Last November, during the Porc d'Or annual gala, La Almenara farm was awarded the "MAPA Special Award" by the Spanish Ministry of Agriculture, Fisheries and Food. We visited the farm with the manager, Sara Beitia, Emilio Magallón (co-owner), and Roberto Bautista (head of integrated farms from Inga Food in Aragón) (Photo 1).

Photo 1: From left to right: Emilio Magallón, Sara Beitia, and Roberto Bautista with the “MAPA Special Award” trophy.

This farm, located in Tauste, in the Spanish province of Zaragoza, had its first farrowings in September 2019, houses 3300 sows delivering weaned piglets. In addition to having technical support from Inga Food, the farm's integrator company, the farm belongs to a group of partners that includes Emilio Magallón, who is very involved and contributes extensive production knowledge. The rest of the partners are Noel Alimentaria, Antonio Soler, and Luis Carlos Cuartero.

La Almenara farm has multiple certifications including animal welfare certified -IAWS (Interporc Animal Welfare Spain), the WelfairTM animal welfare certification, as well as ISO 9001, which allows its production to be destined as a priority for the strict British market.

Personnel, the key to success

We must take care of the staff so that they can devote themselves to taking care of the animals, and at La Almenara, the staff care is undeniable. The individual and modular changing rooms solve the frequent problem of having more workers of one sex than what was planned according to the size of the changing room. More privacy for changing and showering can be especially important for certain people and cultures and is something to consider when attracting new workers to farms. Note: The locker rooms have a small safe in each dressing room for valuable belongings, such as cell phones.

Photo 2: A motivated, trained team with low turnover is undoubtedly key to the success of the farm.

The staff, consisting of 12 workers plus the manager, is split into three shifts with an intensive 7-14 hour workday, with two people in the afternoon and working every third weekend. Holidays and vacations are planned well in advance to better organize the staff. Workers travel from the surrounding towns of Tauste and even from the city of Zaragoza, some 40 km away. To facilitate coming to work, the company provides the workers with three vehicles.

It is very good news for the industry to see a young woman like Sara Beitia (an animal health and science graduate with a master's degree in swine health and production) at the head of the farm. Sara tells us that the level of employee turnover is less than 10%. In fact, the vast majority of the employees were there during the start-up of the farm. At that time, only three of the workers had previous experience. Learning plays an important role on the farm and regular internal training sessions are organized on various topics (biosecurity, management, health and safety, etc.) according to the needs that are identified.

It is worth noting that the farm's production data is updated and visible in the cafeteria/training room to keep everyone involved and motivated.

Photo 3: The main production indicators are visible in the cafeteria/training room and updated to involve the team in the results.

Commitment to health

The commitment to health begins with a simple and functional design that helps to ensure that the biosecurity of the facilities is maintained. The farm has spacious barns that are fully connected by a covered central corridor. This type of design makes it very easy to clearly define the clean and dirty areas of the facility. There are also two benchesacting as shoe barriers (at the entrance to the changing room from the outside and at the entrance to the barns) that help reduce the risk of pathogen entry and contribute to keeping the dining area, office, etc. clean.

Photo 4: A simple and functional design helps maintain farm biosecurity.

The farm has an incinerator and a hydrolysis system for carcass disposal. The use of both systems combined provides great flexibility and optimizes the use of every system to eliminate the material for which it is most suitable, taking into account that both are systems that minimize sanitary risks.

The farm's replacement animals come from an external source every two months and are housed in a quarantine at one end of the facility where they are kept in isolation until tested.

As part of the program to combat antimicrobial resistance, the farm periodically reviews its antibiotic usage (PresVet report), which stands at 9.58 mg/PCU (January-June 2022).

Commitment to animal welfare

In order to minimize the time that sows are kept in stalls, this farm uses a "mate and release" system. In the mating area, the sows are housed in stalls that have self-catching systems. Here they are confined for 3 days post-mating and then released to rejoin the group.

Photo 5 (left): Mate and release area with auto-capture stalls. Photo 6 (right): Sows have access to a variety of enrichment materials.

When gestation is confirmed, the sows are moved to pens with electronic feeders. There are static groups of 40 or 60 sows with a ratio of one feeder for every 20 dams to minimize waiting times and fights. These machines do not require a previous learning process to be in place prior to mating.

Photo 7: Confirmed gestation pens.

Photo 8: The gestation pens have one electronic feeder for every 20 sows.

In order to improve feed consumption and reduce feed wastage, the farm works with liquid feed, except in confirmed gestation where wet/dry feeding is used. During mating and early gestation, animals are grouped by body condition since the self-catching stalls do not allow for individualized feeding. In this area, the females are fed twice a day in a continous trough with a valve for every five animals. All females have access to drinkers at all times.

When sows are moved to the gestation pens after pregnancy has been confirmed, they are assigned a feeding curve that is reevaluated at three weeks. The daily sow feeding routine starts at 2:00 a.m. and daily alerts are checked for sows that have any incidence (loss of ear tag or sows that have not eaten). Early detection and attention to sows with problems is a key tool in improving their welfare and productivity.

Gestating sow pens have a significant proportion of solid floor, which facilitates the incorporation of enrichment material such as straw.

Photo 9: The resting areas in the gestation pens have a solid floor, which facilitates the incorporation of straw.

The farrowing barn has dual corridors, one on each side of the rooms. One is for personnel and the other is for moving animals and has a non-slip floor. The farm does not synchronize farrowing. Lactation lasts an average of 27 days and the piglets receive, with few exceptions, a single solid feed in the nursery with a feed consumption of around 200 grams per weaned piglet. To facilitate adaptation to the nursery, they are provided the same feed that they will find once they are weaned. Occasionally, the dividers of the farrowing pens are lifted to allow shared lactation and to reduce stress at weaning.

Commitment to sustainability

The farm installed a slurry cooling system in 11 of the 15 farrowing rooms. By means of a closed circuit installed under the pits, heat is extracted from the slurry pits to cool the slurry and, thus, reduce emissions. On the other hand, the geothermal pumps, by capturing this heat, generate the energy necessary to heat the underfloor heating in the farrowing rooms. Therefore, this system provides three benefits:

- it provides significant savings in heating costs

- the cooling of the slurry reduces ammonia emissions by 70%

- it also contributes to improving the environment for the animals and the personnel in the rooms where it is installed.

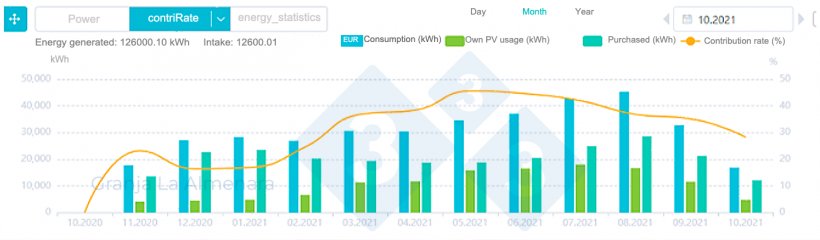

The farm also has photovoltaic panels that provide, on a yearly average, 36% of its electricity needs, reaching up to 45% in summer. There is a project to increase the number of photovoltaic panels, as well as to install a wind turbine in order to achieve total energy autonomy and to sell surplus energy to the grid.

Figure 1. Monthly evolution of the energy generated by the photovoltaic panels and the energy consumed.

Implementing precision livestock farming and technology

La Almenara is an example of how to successfully implement different elements of precision livestock farming. For example, we will mention data management and animal counting.

Today, farms provide an infinite amount of data, but what is important is to transform it into information that can be used to have a better understanding of what is happening on the farm and to act accordingly. La Almenara does an excellent job at this.

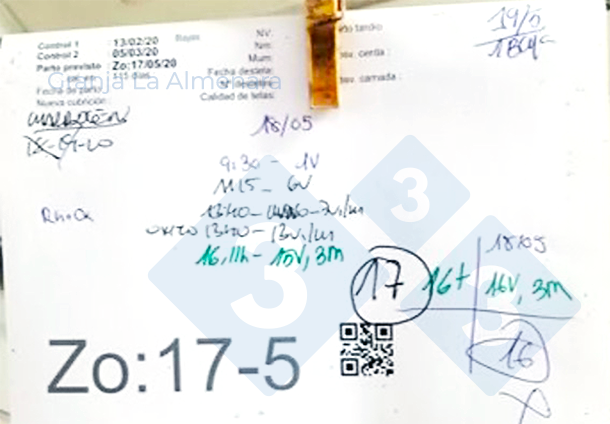

On a farm of this size, recording and transferring information is key. The sow cards have QR codes that allow easy cell phone access to record, consult, and edit information, which speeds up data entry and reduces the chance for error when transcribing information.

Photo 10: QR codes on the sow cards to facilitate data entry.

Photo 11: More screens and less paper in an office that transforms data into information.

Another practical application of precision livestock farming is the use of cameras for animal counting. Counting piglets at weaning without mistakes is not an easy task. The farm has an automatic animal counting system, with a camera installed in the piglet loading corridor. The system counts the animals as they pass through, subtracting them if they turn around. This system streamlines the loading process and provides the farm and the integrator confidence in the actual number of piglets loaded.

The combination of a consolidated, well-trained, and committed work team, with excellent technical support, along with good health management with high biosecurity measures and functional, well-designed and maintained facilities, make La Almenara a very efficient farm that optimizes sow feed consumption (39.35 kg of feed/sow/piglet at 27 days and an average weight of 6.4 kilograms in 2022), achieving an excellent piglet production cost with a high level of animal welfare.