Airborne transmission of infectious agents continues to be one of the most important problems for the swine industry. Examples of pathogens that are transmitted by air include Influenza viruses, Mycoplasma hyopneumoniae, PRRS virus, Aujeszky’s disease virus, viruses responsible for vesicular diseases, Salmonella, and the Porcine Epidemic Diarrhea virus. Unfortunately, there are limited options to limit the spread of airborne pathogens.

After being emitted by an infectious host, virus and bacteria that become airborne travel in the air attached to particles of various origins and sizes. The dust, especially dust originating from agricultural facilities with animals, includes contaminants (of organic and inorganic origin) that, after being inhaled, may have a detrimental effect on animal performance and the health and well-being of animals and farmers. Dust causes irritation of the respiratory tract, increased susceptibility to respiratory diseases, and it plays a significant role as a vehicle of transmission for viruses and bacteria that can cause disease in livestock.

The most direct strategy to decrease the concentration in the air of airborne pathogens is dust reduction. There are many strategies that are able to decrease the amount of dust in livestock facilities. These include different feeding related strategies (i.e. liquid feed techniques, pelleting feed and the use of certain feed additives), the use of water or oil to dampen surfaces, barn ventilation and air distribution systems and electrostatic particle ionization systems.

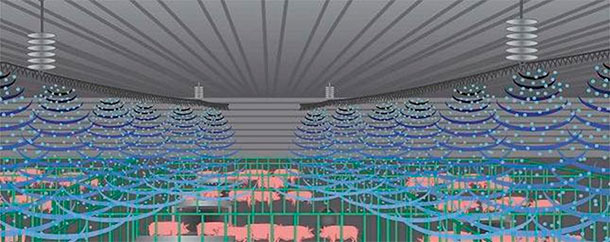

The use of ionization as a means to eliminate particles from the air is not new to animal agricultural. The effect of this technology has been demonstrated previously in research projects on poultry as well as with swine. This is considered one of the most effective technologies for removing particles from the air compared to more conventional technologies such as the spraying of water or oil, changes in ventilation rates or changes in air distribution. Nowadays, there is a commercially available particle ionization system known as EPI (Electrostatic Particle Ionization) technology. This technology consists of a long ionizer bar with sharp point electrodes connected to a high voltage power supply (-30 KV) that generates and releases a high negative ion output into the air. The interaction of these ions with airborne particles results in the particles receiving a negative charge (ionization). This process causes the particles to attract to nearby surfaces (i.e. walls and ceilings) and may be cleared from the air (figure 1).

Figure 1. Illustration of the EPI system in the farm. Source: www.epiair.com

Experimental results in different commercial farms have analyzed the economic aspect of this technology. Results of these trials demonstrated that the implementation of this ionization technology increased the average daily gain by 12.2% and decreased the mortality by 1.2% in pigs from wean-to-finish facilities of a large swine production company during a 12 month period.

Subsequently, Montserrat Torremorell and Carmen Alonso from the University of Minnesota have carried out a group of studies with the goal of analyzing the efficacy of the system against airborne particles, specifically against PRRS, influenza and PED viruses present in aerosols and generated by infected animals.

In order to study the capabilities of the EPI system for the removal of these microorganisms from the air and the effect on their viability once exposed to the presence of these ions, different farm conditions were analyzed. Different air samplers and molecular techniques such as quantitative PCR and virus isolation techniques were used to demonstrate the presence of live viruses. Results from the air samples of these studies demonstrated that the EPI system was efficient at removing particles from the air. However, this efficiency was dependent on the particle size. The removal efficiency was 76% on particles that ranged from 0.5-1.0 microns and 80% on particles from 1.0- 3.0 microns.

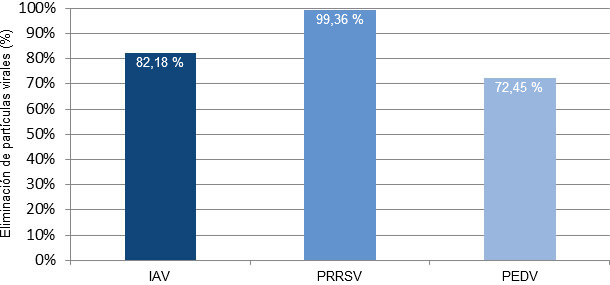

Results related to the presence of viruses measured with a specific cyclonic air collector demonstrated that the system had different efficiencies at removing different pathogens from the air (Graphic 1). PRRSV was eliminated from the air in higher quantities, followed by influenza and PEDV. The results of the isolation of the viruses in the air samples demonstrated the presence of live viruses after the aerosols were exposed to the ions.

Graphic 1. Virus removal efficiency (%) after treating the aerosol generated

from pigs acutely infected with influenza (IAV), PRRSV and PEDV

Understanding the potential of these air cleaning technologies moves us a step closer to effective mitigation of the spread of pathogens through the air and the improvement of the health of the animals on the farms and the people that work with them.

Figure 2. EPI system in a swine facility and cyclonic air collector

(device used in field projects to collect air samples in liquid media). Courtesy of Dr. Gil Patterson