We noted in the previous article that possible changes are on the horizon in the European Union regarding the housing of sows during farrowing. Currently, there are already some systems developed by commercial companies, in collaboration with universities and research organizations, which have already provided some preliminary results. However, the practical implementation of the alternative systems to farrowing crates is still scarce in a large majority of countries, except for those where the use of permanent crates has already been banned (Sweden in 1987, Switzerland in 1997, and Norway in 2000) or those where outdoor and/or organic production has a high prevalence (UK, with 40% outdoor production, or New Zealand, with 45%). The decision to change housing can cause uncertainty, especially when different prototypes exist. At this point in time, it is difficult to predict whether possible legislative changes in relation to abandoning the use of crates will be accompanied by more concrete specifications on aspects such as minimum space requirements or the possibility of temporary sow restraint. We know that Germany intends to ban total sow restraint during farrowing in 2035, which would allow temporary confinement, and which will require a minimum of 6.5 m2. From here on, we will have to pay attention to regulatory proposals and provide information from data evaluated with scientific criteria to decide which systems would best suit each farm, considering both animal welfare and economic sustainability aspects.

Alternative systems to the farrowing crate can take the form of individual or group housing, or a combination. At present, we can divide these systems into three main types: systems that allow temporary confinement, systems without any confinement, and group systems. The main characteristics and some specific examples of individual housing systems are described below.

Individual housing without any type of confinement

These are pens in which the animals are housed individually and are not subjected to any type of movement restriction.

The simplest model would be what is known as "simple pens" (Photo 1). These designs are similar to the current farrowing crates but without the crate. The minimum space required would be that which, at minimum, allows the sow to turn around without difficulty, as well as allowing some protection of the piglets, for which some elements can be included.

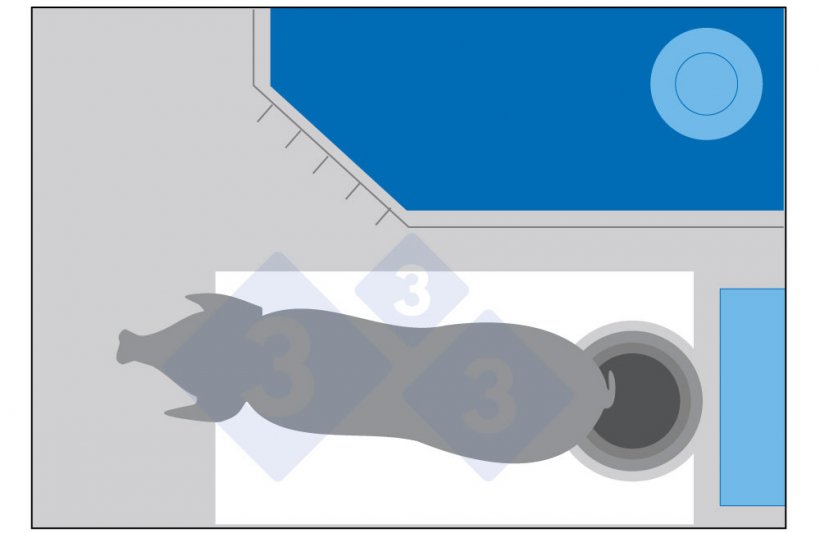

Photo 1. Example of an unmodified pen without crate (photo: www.freefarrowing.org).

However, one of the major problems in "repurposing" the current spaces occupied by farrowing crates into these simple pens is that some studies have shown that the lack of space prevents the sow from properly defining functional areas for defecation, resting, and feeding, as well as increases the risk of crushed piglets due to a lack of a proper nest. Some research (Andersen and Pedersen, 2011) showed that the sow prefers to keep her head as far away as possible from the resting and feeding area when defecating. In conventional cages, the elimination area is always the same, but in alternative systems, pen hygiene will depend on factors such as whether the sow has enough space to establish these different functional zones, respecting her ethological preferences. In addition to this limitation, there is also the need for sufficient space to create a nesting and protection area for the piglets.

Figure 1. If the sow can move but has no more space than she does currently, she may turn her back to the trough to defecate and end up soiling the area in front of the trough.

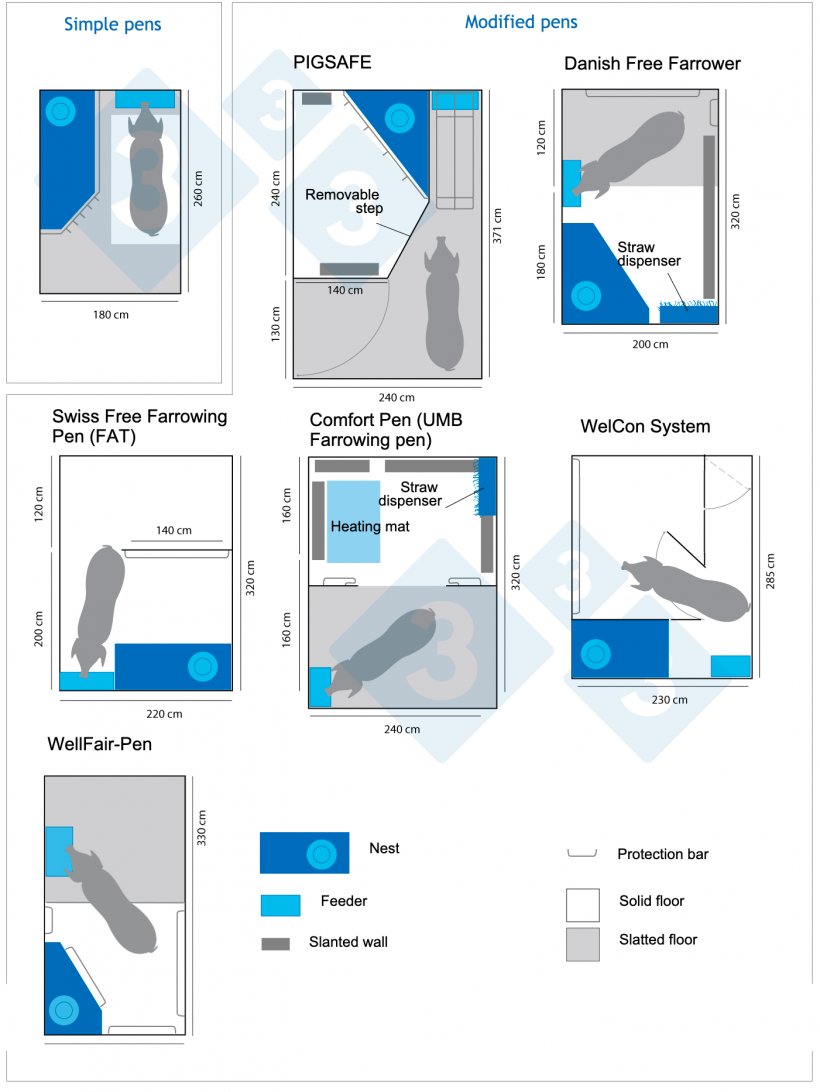

Modified pens. These pen designs add space to define resting, feeding, and defecation areas. In addition, they incorporate elements such as sloped walls, piglet protection systems, and nests. The space these systems take up varies depending on the manufacturer (between 5 and 8.5 m2) however, it is considered that they start to be more effective with at least 6 m2. The advantage of these systems over semi-confinement systems is that they allow the expression of full nesting behavior, although it is true that at present crushing during the first days is still higher. To avoid crushing, good nest management (ease for the piglets to find and use the nest) is considered crucial, especially when temperatures are high and the piglet is less likely to use the nest. Another key aspect to decide is the type of floor: full slat floors are associated with better and easier hygiene, however, in these non-confined systems whose objective is to allow nesting behavior, it is more necessary to consider some area and floor type to provide the appropriate materials. Finally, the accessibility and safety of the personnel to perform certain practices must also be considered, hence some of these systems also incorporate a system to temporarily enclose the sow.

Photo 2. An example of prototypes of this type of housing (PIGSAFE). Source: Emma Baxter.

Figure 2. Different models of farrowing pens with no confinement. Infographic created by 333 based on information from www.freefarrowing.org.

Semi-confinement systems or with temporary constraints

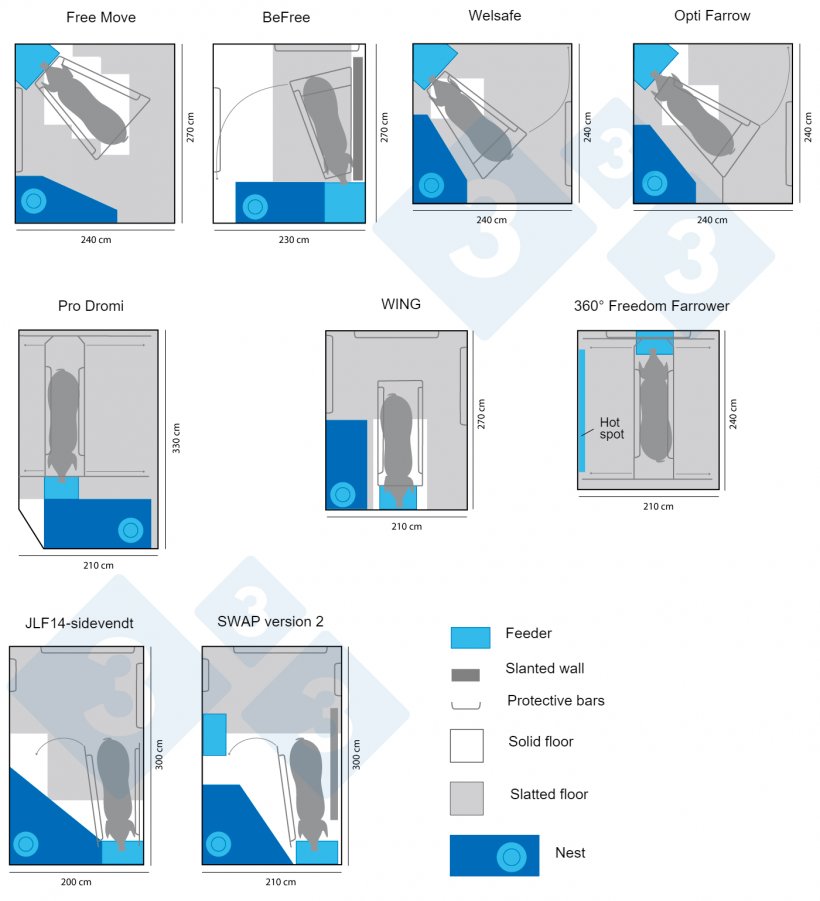

Some of these systems were initiated by opening the farrowing crate during lactation (5-7 days) to allow for greater sow movement (Baxter et al., 2018). These systems typically use slat flooring and occupy around 4.3 m2. However, improved designs are now available, taking into account more aspects of the sow's biological needs, which provide more space (6 m2 and up).

The key points considered in these systems are again to provide enough space for the sow to define her functional zones, to design a nesting area that is attractive to the piglet and quickly utilized, and to consider aspects of management, safety, and accessibility for the farmer.

Although some studies suggested that two days of confinement might be sufficient to reduce mortality due to crushing, Danish and Austrian data indicate that the 4 days after farrowing are days of reduced sow activity, so this period of temporary restriction would be a good compromise between piglet and sow welfare and personnel management needs.

In conclusion, one of the great challenges for both zero confinement and semi-confinement systems will be to keep neonatal mortality under control, especially in hyperprolific sows.

Figure 3. Different commercial models of semi-confinement farrowing crates. Infographic created by 333 based on data from www.freefarrowing.org.

Previous articles have provided data on the commercial operation of systems such as SWAP and JLF15 as well as a design in Italy. You can also obtain a comparison paper of 10 of these systems in a showroom at the Danish SEGES institute. On the freefarrowing.org website you can view tutorials and get more information on other commercially available models.