Artificial insemination (AI) in swine is a highly technified process at any of its stages: facilities and management of the boars, optimization of the ejaculates collection and processing, semen checking, semen packing and storage and insemination techniques. The constant AI development allows to process a large number of high quality semen doses and, on the other hand, new techniques allow a higher production of semen doses per boar. The goal of the research and development teams is to satisfy the great demand for technology required by AI.

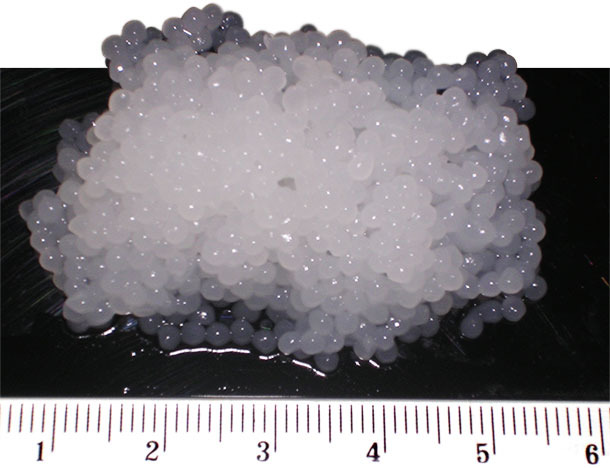

Figure 1. Undiluted pig sperm capsules

Properties and uses of encapsulation

The goal of encapsulation is to encase an active ingredient in a semipermeable membrane with the aim of protecting it from the external environment, keeping the activity of the active ingredient complete for as long as possible. Another property of this system that is very interesting in many fields is the ability to release the compounds that are inside the capsule gradually. This phenomenon allows a gradual and continuous transfer (or as pulses) of the active ingredient depending on certain physical or chemical conditions. These properties are very useful in several fields, such as the chemical, pharmacological, agricultural, cosmetics, food industries, etc. In the field of biotechnology it has been used to encapsulate active biological material, such as cells or tissues, creating what has been called bioartificial organs. Their use allows the treatment of central nervous system, endocrine and immunological diseases and cancer. Semen encapsulation was initiated by Nebel et al. in 1985.

Encapsulation in swine

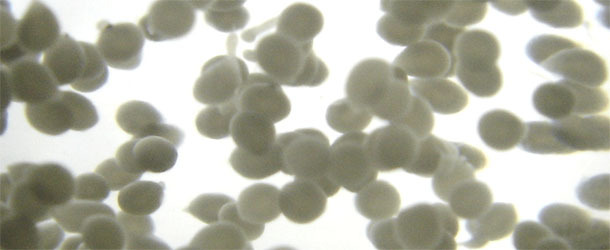

Encapsulated semen has very interesting properties that also change some of the basic concepts of the AI technique. The creation of the capsule matrix is made with natural polymers biocompatible with sperm. Spermatozoa are trapped inside them, immobilized without it entailing damage to their structure and functionality. On the other hand, the membrane that constitutes the capsule keeps a selective permeability that allows the passage of low-molecular-weight molecules such as glucose, a main component on the refrigerated semen extenders, and it blocks the passage of macromolecules, such as immunoglobulins (Lim and Sun, 1980), and of microorganisms that cause alterations in the sperm during their storage. These situations create optimal conditions for the refrigerated storage of encapsulated sperm at 15ºC (Figures 1 and 2).

Figure 2. Diluted pig semen capsules

Once introduced in the sow's genital tract, the structure of the sperm capsules becomes more viscous, allowing a better retention in the uterus and partially avoiding the semen dose reflux (Nebel et al., 1996). Sperm losses that occur during the sperm transport due to different mechanisms are also avoided. We have been able to confirm these facts in our studies, in which we saw a higher number of sperm in the oviducts of the sows inseminated with a single dose of encapsulated semen in comparison with sows inseminated with two doses of non-encapsulated semen (Sánchez-Sánchez et al., 2014).

In the last years, one of the most desired goals to optimize the AI technique has been to reduce the number of semen doses per inseminated sow, for which different methods, such as the determination of the moment of ovulation by ultrasonography, the induction of ovulations with GnRH agonists, and semen encapsulation are used. A very appreciated property provided by the encapsulation system is the sequential release of the sperm inside the capsule, allowing for the release of sperm along time. This is useful for generating waves of sperm to cover the sow's ovulation period.