Every complete farm biosecurity program in a pig farm must give full consideration to every movement (i.e. live/dead animals, people, and supplies) into and out of the clean animal production space and across clean/dirty zone boundaries. For each of these movements, a biosecurity protocol is required. In this article, we will focus on the biosecure management of deadstock.

There are several deadstock management options. Some of them, such as incineration are performed by the farm personnel, and others, such as the rendering and the hydrolysis use a specialized external collection service that will take the material (deadstock or hydrolysis subproduct) to the corresponding treatment plant.

Managing carcasses that range from 1 to 250 kg is a farm task that poses some special challenges and needs to be addressed properly to ensure worker safety and farm biosecurity. When considering farm biosecurity, the movement of dead animals and other tissues for disposal (e.g. placentas and fetuses) is an event that poses a risk for pathogen spread and cross contamination on several levels. The following aspects of biosecurity need to be considered:

- Biomanagement (internal biosecurity) - risk to disseminate an infection within the farm via vectors (i.e. insects and rodents) and fomites (i.e. boots, coveralls, tools, etc.)

- Biocontainment (preventing spread to other farms) - risk for pathogen spread to the external environment and transmission by vectors and fomites

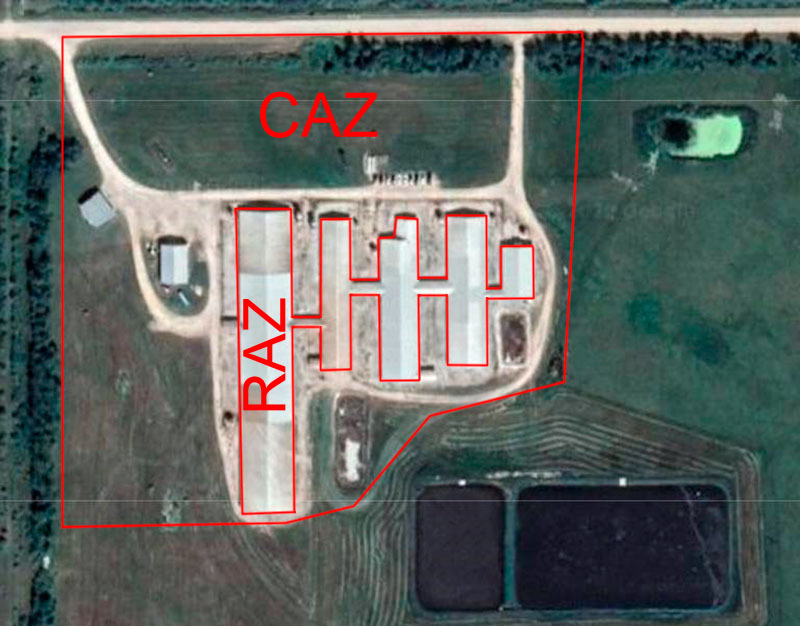

- Bioexclusion (external biosecurity) - risk of a new pathogen entry when crossing the clean/dirty boundary between the animal space (i.e. restricted access zone or RAZ) and the outside of the farm premises (i.e. controlled access zone or CAZ) (Image 1).

All steps needed to be securely performed, so it is critical that carcass removal is included in the biosecurity protocols of the farm and is a part of every workers’ training.

Let’s review the key biosecurity messages:

1. Deadstock removal location from the RAZ

All carcasses should be moved to a properly designated location that can be accessed from outside the restricted area. This placement should be enclosed, easy to clean, and with direct access to the outside controlled accessed zone. There may be single or multiple locations (i.e. lactation, gestation, GDU, etc.) depending on the farm size. Ideally, the locations should be separated from other transition zones (i.e. load in/out, supply entry, personnel entry, etc.) to avoid cross contamination. Finally, the deadstock management area and the designated equipment (i.e. carts, wheelbarrow, baskets) should always remain organized and clean.

2. Transition protocol between zones (red line)

The RAZ red line in Image 1 divides the clean side (i.e. inside) from the dirty side (i.e. outside or the controlled access zone) where the deadstock pick-up/storage location is. The hypothetical boundary between the RAZ and the CAZ can be a red line painted on the floor or it could coincide with a physical barrier (i.e. limit of a door or elevated panel) that will prevent inappropriate movement of personnel and equipment.

Farm personnel should collect the deadstock materials from the designated point using specific protective personal equipment (such as coveralls, footwear, and disposable gloves). These specific equipment for deadstock management should remainoutside the clean area. It is important to highlight that the designated worker or workers in charge of carcass disposal should only return to the farm after a designated downtime and a biosecure re-entry to the facility. It is highly recommended to perform this movement of carasses to the pick-up/storage location at the end of the workday or the shift.

3. Design and location for deadstock pick-up/storage at the CAZ

What is the ideal design of this area? Regardless of the treatment chosen, we will highlight some important design aspects:

- It should be protected so that scavenging animal and birds cannot have access to the materials (Image 2)

- Should easily identify the clean and dirty boundaries for farm personnel considerations so they can follow the corresponding biosecure measures when returning to the controlled zone (Image 3)

- Structures and ground cover of the deadstock management area should be made with durable material and must be part of the routine farm maintenance so they withstand over time under different weather conditions (Image 3)

What is the ideal road designed for vehicles to access and remove the deadstock container (dead animals or hydrolysis/ incinerator subproducts)?

Ideally, clean vehicles (i.e. supplies, semen, genetic stock) and dirty vehicles (i.e. trucks for feed, deadstock removal, slaughter/cull shipment, manure management) should have a distinct entry and exit location (Image 3). In the case of the external collection and the hydrolysis services, the transfers to and from dirty vehicles should occur at the boundary or fence of the controlled access zone (Image 4) but accessed by the farm personnel from the CAZ.