In recent decades, artificial insemination (AI) has become an established reproductive technique in swine production. It is estimated that 90-100% of females on farms in major producing countries (with the exception of China) are artificially inseminated. However, in order to supply semen doses and ensure that they are produced with efficient quality control, semen doses that were normally produced on-farm began to be produced at specialized premises, such as artificial insemination centers (boar studs).

Among the benefits of producing semen doses in boar studs are: the intensive genetic improvement applied to boars with constantly updated genetic indexes, biosecurity, using semen from animals free of specific diseases according to the country's legislation such as scabies, tuberculosis, brucellosis, leptospirosis (through control protocol), classical swine fever, and Aujeszky's disease, and strict quality control applied in all phases of semen dose production from collection to delivery to producers.

In this scenario of centralizing the production of seminal doses, the boar studs are strategically located in regions that facilitate the logistics of distribution via road transport. However, in countries such as Brazil, due to its geographic size, long distances are generally traveled to deliver semen doses to producers. In a study conducted by Bennemann et al. (2020), evaluating 32 boar studs in Brazil (representing 61.53% of the country's total), the authors verified that the transport of semen doses is carried out with temperature control in 58.06% of the boar studs, covering distances of up to 600 km.

The transport of boar semen doses from the boar studs to the farms is a step that requires careful attention due to factors such as temperature fluctuations and vibrations, which can influence their quality and affect the spermatozoa. Temperature control during transport is essential to maintain the quality of semen doses as fluctuations above 2-3°C decrease storage time and sperm viability.

The use of real-time applications can help identify critical factors in the transport of seminal doses. Sensors connected to devices such as smartphones make it possible to measure and manage various external factors. To date, there are few studies evaluating the impact of transport on sperm, however, Schulze et al. (2018) demonstrated, using a mobile sensing app with custom programming, that artificial vibration emission has a frequency-dependent effect (up to 300 rpm; simulating a high-impact road) on the quality of semen doses using a short-term extender and agitated for six hours(Table 1).

Table 1. Effect of different vibration emissions (100 and 300 rpm) for six hours immediately after processing the ejaculate from different boars (n= 20) diluted in short-term extender on sperm quality parameters.

| Parameters | Control | 100 rpm | 300 rpm |

|---|---|---|---|

| Mitochondrial activity (%) | 87.3a | 81.2a | 74.2b |

| Plasma/acrosomal membrane integrity (%) | 80.3a | 73.7a | 57.3b |

| Total motility after TRR 30 (%) | 80.7a | 78.0a | 34.6b |

| Total motility after TRT 300 (%) | 69.7a | 64.2a | 24.3b |

Values expressed as average. TRT 30 = thermo-resistance test after 30 minutes of incubation at 38ºC. TRT 300 = thermo-resistance test after 300 minutes of incubation at 38°C. a, b Different letters indicate significant differences between groups within the row (P ≤ 0.05). Adapted from Schulze et al. (2018).

Paschoal et al. (2021), evaluated the effects of simulated vibrations using a shaker at 200 rpm for four hours and also found a detrimental effect of vibrations on sperm motility parameters and plasma membrane integrity, compared to the control group (not subjected to vibrations). The extenders used (short and long-term) did not influence the damage induced by agitation.

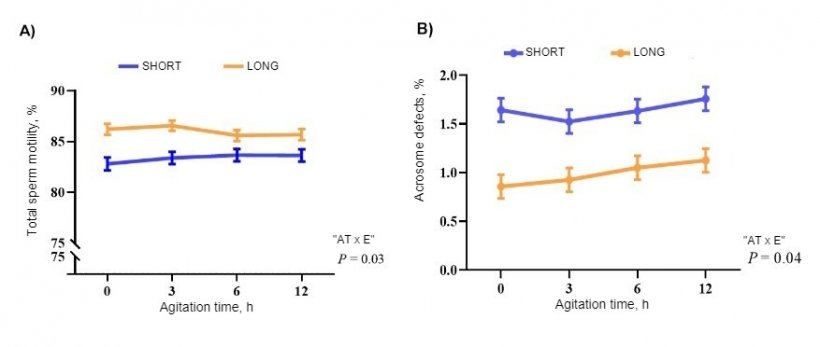

In another study, conducted by Tamanini et al. (2022), evaluating the effect of vibration exposure time and the influence of the diluent on this response, the authors simulated transport through the emission of vibrations induced by a shaker at 70 rpm during 0 (not subjected to vibrations), 3, 6, and 12 hours with diluted doses in short and long-term extenders. This study was able to verify that sperm motility and acrosomal integrity were influenced by the interaction between agitation time and extender, demonstrating a slight detrimental effect of vibrations on these parameters (Figure 1).

Figure 1. Effect of the interaction between agitation time (AT; 0, 3, 6, and 12 hours) and the extender (E) (long-term, LONG, and short-term, SHORT) on total sperm motility (A) and acrosome defects (B) in porcine seminal doses (n=20 boars). Values are expressed as mean ± SE (standard error).

The biological explanation for the deleterious effect of vibration on spermatozoa has not yet been found. It is believed that agitation induces the loss of CO2 from the liquid phase to the air, causing alkalinization of the seminal doses. In addition, oxidative stress induced by mitochondrial changes also damages cells. Shear stress can alter sperm membrane properties and this mechanical damage generates stress levels in spermatozoa.

Therefore, the transport of seminal doses is a complicated step and to date few studies have been conducted to clarify the effects caused by vibration emission and how to minimize them. In view of this, it is important that transport is done properly, preferably in well-maintained cars and roads. Regular training should be provided to drivers involved in the delivery, and strict real-time monitoring of temperature and other factors should be implemented so that semen doses are delivered with quality assurance.