In 2011, the total cost for producing a 105 kg pig in Spain was 125.0 €. Approximately a 64.3% of this price belongs to the growing and fattening stages. From the total costs in the growing and fattening stages, about an 82% were due to feeding, while the 15.7% were fixed and integrations costs, and a 2.3% was spent on medications.

The main factors that affect the production indices and, as a consequence, the growing and fattening pigs costs are well known: among them, the genetic strain and the commercial kind of pig produced, the feeding, the conditions of the installations and the health condition stand out. Due to this, it is interesting to have representative information of the Spanish pig industry related to the handling characteristics, the installations and the health of the fattening pigs.

So, the main goal of this study was to create a representative database of the pig growing and fattening farms integrated in several Spanish companies.

Data

Between July 2008 and July 2010 data from 764 fattening batches from a total of 452 feedlots pertaining to nine out of 25 of the biggest integration companies in Spain (together they account for about a 20% of the national production of fattening pigs) were collected. In total, 1,157,212 pigs were controlled, and they correspond to the 1.5% of the pigs slaughtered in Spain during the studied period. The majority of the farms are located in Aragón and Catalonia (44% and 35% respectively), an 18% of them are located in Castilla y León, and the rest (3%) in La Rioja, Navarre and Valencia.

The data were collected for each batch using a survey model that was divided in four parts: a) general information, b) installations, c) feeding, and d) production indices.

Results

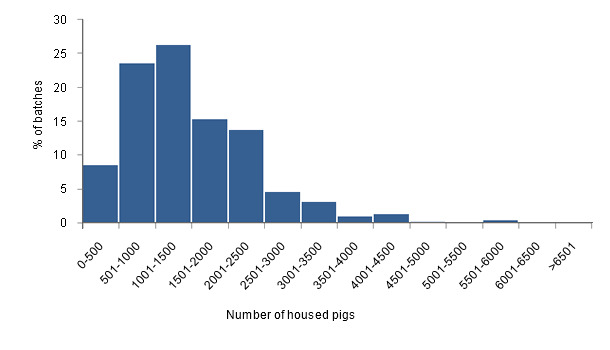

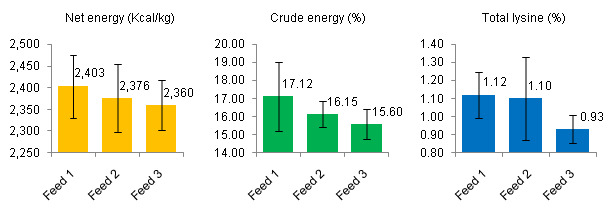

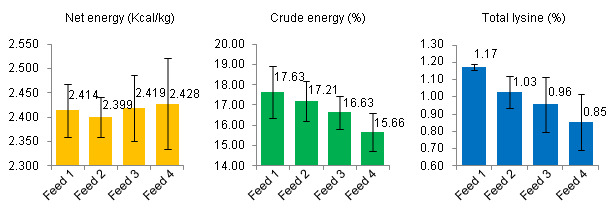

The results of the production conditions are presented in Table 1. Figure 1 shows the distribution of the number of pigs housed per batch, and Figure 2 presents the averages of the net energy (Kcal/kg), crude protein (%) and total lysine (%) contents in the compound feeds used during the growing and fattening stages.

Table 1. Description of the production conditions of 452 pig growing and fattening farms in Spain.

| Variable | Categories |

| a) General information | |

| Year of the entrance of the batches1 | 2008 (33.7%), 2009 (63.5%), 2010 (2.8%) |

| Quarter of the entrance of the batches1 | Jan-Feb-Mar (18.3%), Apr-May-Jun (26.4%), Jul-Aug-Sep (18.1%), Oct-Nov-Dec (37.2%) |

| Kind of farm | S2+S3 (5.3%), S3 (94.7%) |

| Kind of fattened pig | industrial 95-110 kg (86.7%), heavy > 110 kg (13.3%) |

| Segregation of the genders in the pens | mixed (50.2%), segregated (49.8%) |

| Genders present | males, females and castrated (11.7%), males and females (59.5%), castrated and females (23.5%), absent (5.3%) |

| Genetics of the terminal boar | Pietrain (69.9%), white (Lw, Ld or Lw x Ld) (19.6%), Duroc (7.8%), Pietrain x white (1.3%), others (1,3%) |

| Number of origins of the pigs | one origin (54.4%), two or more origins (45.6%) |

| Aujeszky's disease vaccine | one dose (11.1%), two doses (21.9%), three doses (65.3%), absent (1.7%) |

| Circovirus vaccine | no (76.4%), yes (21.9%), absent (1.7%) |

| Mycoplasma vaccine | no (76.2%), yes (22.1%), absent (1.7%) |

| b) Installations | |

| Time since the farms were built | < 10 years (11.5%), between 10 and 30 years (41.8%), > 30 years (8.2%), absent (38.5%) |

| Number of pigs per pen | ≤ 12 pigs (9.3%), between 13 and 20 pigs (87.2%), > 20 pigs (1.1%), absent (2.4%) |

| Percentage of slats on the floor | < 50% slats (27.9%), ≥ 50% slats (69.9%), absent (2.2%) |

| Kind of feeding trough | multi-space (24.3%), single space (54.0%), single space with built-in drinker (20.6%), others (0.2%), absent (0.9%) |

| Kind of drinker | nipple (88.7%), bowl (6.6%), only the drinker built in the feeding trough (2.7%), absent (2.0%) |

| Kind of control of the airing | manual (27.9%), automatic (71.2%), absent (2.0%) |

| System for the humidification of the air | no (87,8%), yes (10,3%), absent (1,7%) |

| c) Feeding | |

| Number of compound feeds used | two (0.7%), three (75.0%), four (24.3%) |

| Physical presentation of the compound feed | pellets (90.9%), meal (9.1%) |

| Frequency of the antibiotics treatments | up to two times (37.8%), three or more times (61.3%), absent (0.9%) |

| Administering route of the antibiotics | water (1.1%), compound feed (21.3%), injection (0.2%), water + compound feed (13.9%), compound feed + injection (9.1%), water + compound feed + injection (51.3%), absent (3.1%) |

| Source of the drinking water on the farm | well (23.2%), river (17.7%), public water network (36.5%), others (8.4%), absent (14.2%) |

| Water treatment water on the farm | no (37.8%), yes (55.8%), absent (6.4%) |

1 The batch was considered as the experimental unit (n=764).

Figure 1. Distribution of the number of pigs housed per growing and fattening batch (n = 764 batches).

Figure 2. Averages and standard deviations of the net energy (kcal/kg), crude protein (%) and total lysine (%) contents of the compound feeds used during the growing ad fattening stages.

Figure 2. Averages and standard deviations of the net energy (kcal/kg), crude protein (%) and total lysine (%) contents of the compound feeds used during the growing ad fattening stages.

a) Three compound feeds (555 batches on 347 farms).

b) Four compound feeds (218 batches on 116 farms).

The average number of pigs housed per batch was 1,515 ± 949 with a minimum and maximum value of 233 and 6,198 respectively. The 80% of the batches housed between 500 and 2,500 pigs.

Factors such as the genetics of the terminal boar, the sex/gender and the segregation between them in the pens, the number of compound feeds used and the physical presentation of the compound feeds were directly related to the kind of fattened pig or the final weight. In this sense, the 82% of the farms that produce industrial pigs (95-110 kg) have Pietrain terminal boars, while the 72% of the heavy pigs (>110 kg) producing farms use Lw, Ld or Lw x Ld males, and the 28% of them have Duroc terminal boars. With respect to the sexes/genders present, the 70% of the industrial pigs farms have entire males instead of castrated males. Nevertheless, there are no entire males in any of the heavy pigs farms. It was also seen that in half of the industrial pigs farms they separate the sexes/genders in the pens, while in the 100% of the heavy pigs farms they do not carry out this kind of handling. Approximately an 84% of the industrial pigs farms use a feeding program in three stages during the growing and the fattening, and all the heavy pigs farms use four stages. With respect to the physical presentation of the compound feeds used, all the industrial pigs farms use pelleted compound feeds and the 74% of the heavy pigs farms use meal.

With respect to the number of origins of the pigs and the frequency of the antibiotic treatments during the growing and the fattening stages, it was seen that about the 67% of the farms that filled its installations with pigs from two or more origins carry out three or more antibiotic treatments.

The last relationship seen was with respect to the traits of the drinking water. In this way, the 82% of the farms that obtain it through the public water network do not carry out any kind of water treatment in the farm.

We also see that the composition of the compound feeds on the farms integrated under a same company is very specific. Nevertheless, we find differences between the values of the different companies. The high variability seen in the net energy levels of the "compound feed no. 4" was probably due to the fact that almost half of the farms that use four compound feeds produce industrial pigs, and the level of net energy consumed on these farms is a little bit higher than the one on the farms that produce heavy pigs.