Introduction

The planning of a new pig unit or remodelling of an existing one starts with the biological assumptions for the production that is going to take place in the unit. However, designing the pig unit is more complicated today than earlier due to the fact that animal welfare legislation in some countries requires that sows be group-housed during gestation. This means that there are a lot of alternative system designs available. Moreover, pen design needs to be considered according to the number of animals in each group and their management. Building dimension or building width in particular is another factor that greatly influences design of the facility. Similarly, input of feed and output of animals and animal waste must be considered carefully while designing livestock facilities. Basic considerations and examples of how various factors affect design of pig housing will be presented in a series of five articles – the first one contemplating general biological design considerations.

Designing the sow unit

The fundamental assumptions that determine the preliminary design of the sow unit are the following factors:

- sow reproduction cycle and weaning age

- genetics

- cross-fostering strategy

One of the integral parts of pig biology is variation. Thus, weaning to mating interval, farrowing rate and length of the gestation period varies between individuals and over season. On the contrary building dimensions are fixed and cannot be varied. Therefore, the design is always a compromise that must meet certain production assumptions, but it can never be exact.

Reproduction cycle

Generally, a sow herd is divided in batches according to the reproduction cycle. Thus, number of days from weaning to mating is 5 days average with a variation from 4-7 days and standard length of the gestation period is normally 116 days plus minus 3 days.

The weaning age determines how long time the sow stays in the farrowing unit. According to EU regulation piglets cannot be weaned at less than 3 weeks of age and only if they are moved to a unit, which is separate from the sow unit and managed all in all out. Since sows generally are managed in weekly batches and time of mating as well as gestation length varies it means that weaning age must be 4 weeks on average to ensure that all weaned piglets have reached an age of at least 3 weeks of age. In reality, average weaning age is 26 days in a 4 week weaning system, which allows a couple of days for cleaning and disinfection of the farrowing unit. Thus, a 4 week weaning system comprising 1-week interval between sow batches means that the reproduction cycle is 5 + 116 + 26 = 147 days or 21 batches. Similarly, a 5 week weaning system comprising 1-week intervals between sow batches may be calculated as 5 + 116 + 33 = 154 days or 22 batches 1-week batches.

Batch systems

The one week sow batch system is the most simple regardless of weaning age and it is the most common system since it fits nicely with the sow’s reproduction. Thus, returns are easy to fit in with another batch – due to the 3 week oestrus interval.

Next design constraint is the biosecurity requirement, which means that pigs of the same age should be kept within one section that must be managed all in all out. Building costs decrease with increasing room or building size. In short it means that 1-week sow batch interval is only economical for herds with more than 500 sows ~ 22 sows per batch ~ 250 pigs weaned per week.

However, there are many other systems available including 2-week, 3-week, 4-week and 5-week systems. But in practice only 2- and 3-week systems are manageable in the long run. With longer intervals it becomes difficult to handle cross-fostering and returns. Small herds may use longer intervals between sow batches than large herds and obtain the same advantages as those. Increasing the sow batch interval means that there are more sows in each batch and therefore the number of pigs with similar age increases. Moreover, work load will change – thus, in weeks with farrowings there will be more labour requirement than in between these. An example of the effect of batch intervals on housing design is shown in table 1.

Table 1. Effect of batch interval on pig housing design

| Batch interval | Farrowing sections | Weaning sections | Finishing sections |

|---|---|---|---|

| 1 week | 5 | 8 | 12 |

| 2 week | 3 | 4 | 6 |

| 3 week | 2 | 3 | 4 |

Genetics

Today, there may be considerable variation in number of liveborn piglets among different genetics. Genetics producing many liveborn will not be able to nurse all piglets. Therefore, cross-fostering is required to maintain a high piglet survival rate. The number of liveborn piglets and the cross-fostering strategy determines how many farrowing pens are needed as illustrated in table 2.

Table 2. Requirement for farrowing pens in a 1000 sow herd with 1-week sow interval, 45 sows/ batch, 13 liveborn piglets/litter and 4 week weaning.

| Piglets/sow after cross-fostering | 10 | 11 | 11,5 | 12 |

|---|---|---|---|---|

| Farrowing pens nominal | 225 | 225 | 225 | 225 |

| Farrowing pens for cross-fostering | 68 | 42 | 30 | 19 |

| Farrowing pens total | 293 | 267 | 255 | 244 |

Thus, there are many considerations that must be done when designing the sow unit. Next article will focus on some of the other design requirements of the sow unit.

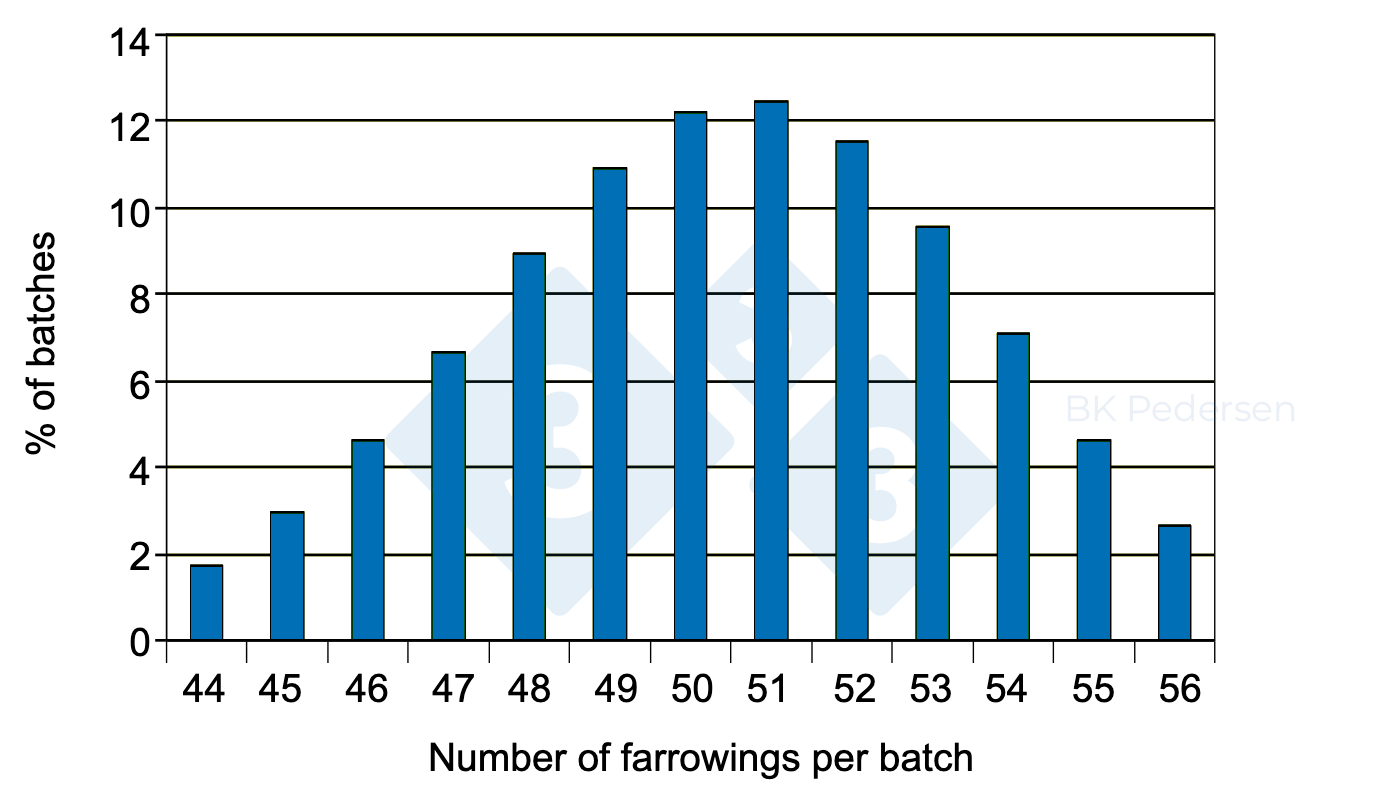

80% farrowing rate, 50 sows/batch

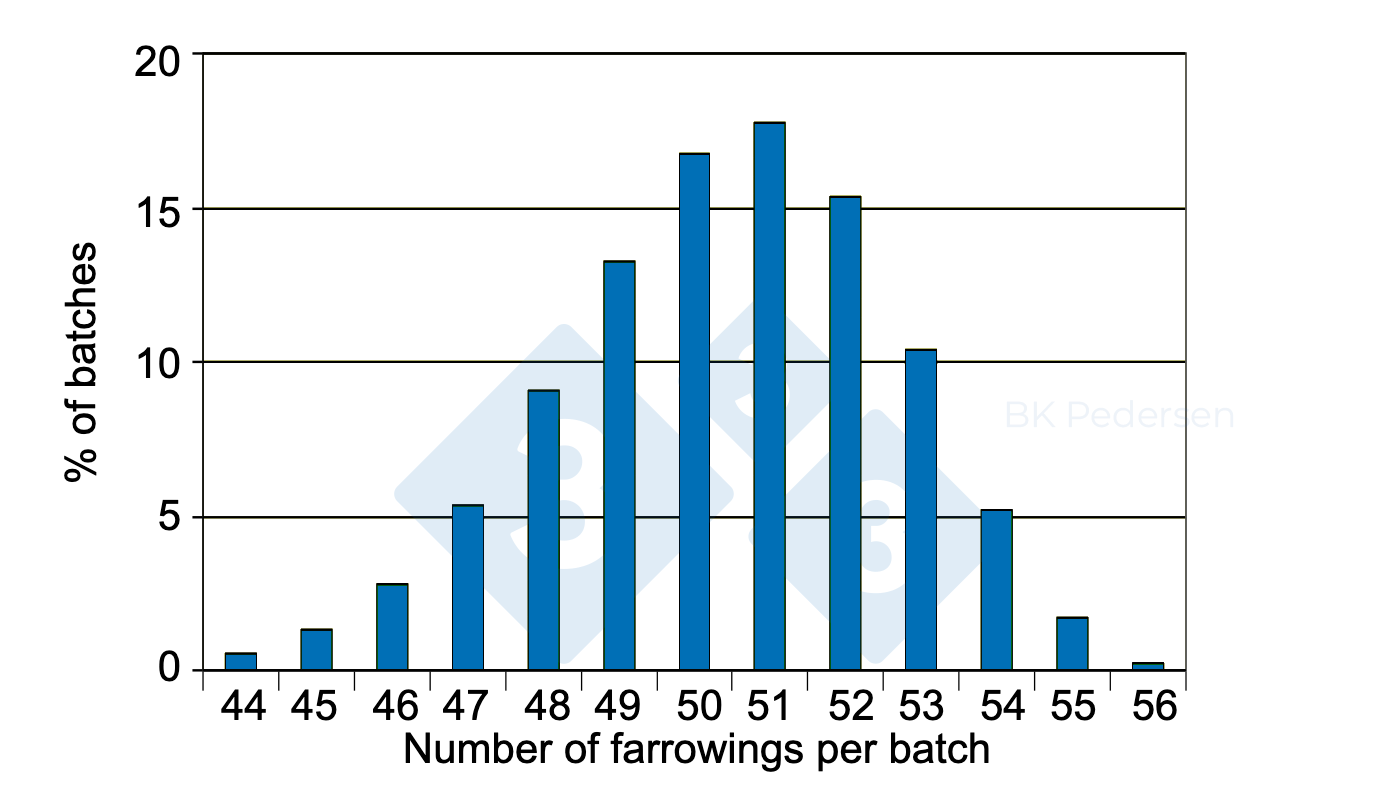

90% farrowing rate, 50 sows/batch