Introduction

The farrowing unit is the most expensive building in the sow unit, but also a very important one. It should provide comfort for the sow and for the newborn piglets as well accommodate the staff, while carrying out management procedures. The objective of the farrowing unit is to deliver as many piglets with a high weaning weight as possible. Of course, technology is only one part of this equation; thermal environment and management also play an important role.

Farrowing unit – considerations

In the first article of this series it was demonstrated that the farrowing unit must be designed for 5 weeks occupation for a 4-week weaning system. Next, each unit should be designed for all in all out management to allow cleaning between batches and close control of the temperature.

The number of pens per room depends on genetics and herd size. Thus, if prolific hybrids such as the French or Danish ones are used 10-15% extra pens must be added per room for foster mothers. These pens will stay empty until foster sows are moved into the section from another farrowing unit. The number of pens required for foster sows may be calculated from the average number of liveborn and the average number of piglets per sow after cross-fostering.

Normally, one farrowing room per sow batch is sufficient. However, in herds with more than 2000 sows it might worthwhile having two farrowing rooms per batch to allocate workload of cleaning pens and moving sows over more days. The American version is to design each farrowing room for 20-24 sows and wean 4-5 days per week.

Temperature control of the farrowing unit is extremely important. Since two types of animals with completely opposite temperature demands are housed in the same unit – this task is not easy. The newborn piglet requires a temperature of 34 C at birth, which is reduced to 28-30 C at weaning, while the sow’s preference is a temperature of 20-22 C at farrowing and 15-16 C at 3-4 weeks after farrowing while milk production and feed intake peaks.

Another important design criteria is noise. According to EU legislation noise levels must be kept below 85dB(A). Studies have shown that the nursing and suckling pattern might be disturbed and milk production may be smaller for sows exposed to similar or higher noise levels. Thus, noise from ventilation fans should be considered.

System design

Fulfilment of the biological requirements of the piglets and sows are fundamental when designing the farrowing unit. Globally, the farrowing crate has been the most common answer to this dilemma. The farrowing crate comes in a wide variety of designs. When it comes to the temperature requirement of the piglets it is most commonly solved by providing a heated creep area. Frequently, the creep area is a water heated mat on one or both sides of the sow. This type of design allows easy inspection of the piglets and effortless cleaning while providing a warm surface for the piglets. However, it also adds extra heat to the room, which is unfavourable for the sow.

A newer type of design comprises a covered creep area with a water heated floor, which is more commonly used in Northern Europe. The covered creep area provides a microclimate for the piglets while the room temperature is not affected. It should provide an area of 0.7-0.8 m2 to allow enough space for all piglets.

During warm periods cooling is required to reduce the negative effects of heat on sow feed intake and milk production. It must be remembered that heat production of a lactating sow is at least twice that of a pregnant animal.

Pen design

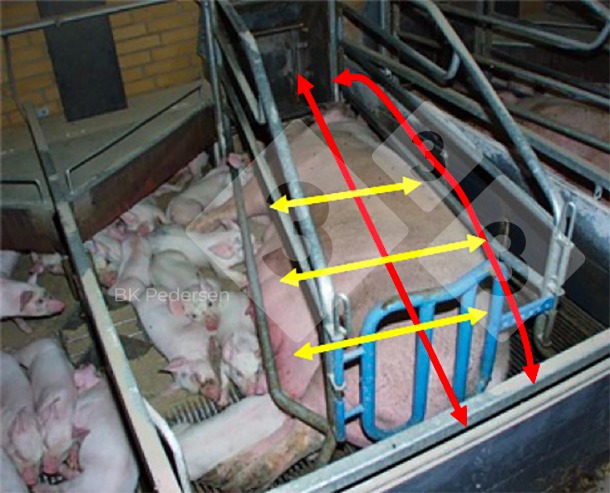

The farrowing stall – the second important feature of the farrowing crate - is meant to control the sow’s body movements while lying down. The Danish pig producers’ research organisation has tested a number of different designs. They recommend pen dimensions of 2.7x1.8 m to accommodate modern prolific breeds. In addition, they propose that stall length should be 200-210 cm long and have an adjustable width from 35 up to 90 cm. The width of the stall should be adjustable to provide space for the piglets according to their growth. At farrowing the pen should be in a narrow to position to force the sow to lie down slow before turning to a recumbent position.

Stall steel bars should be horizontal to allow easy access to the sow. The bottom bar should have fingers and must not impede suckling and nursing behaviour. Danish stalls are always positioned in an angle to allow enough space for the creep area. Moreover, this position allows the caretaker to move freely around the crate without getting out of the pen.

Flooring must not injure the sow or the piglets and should be non-slippery in the sow zone – preferably cast iron 10/10 mm and should provide good pen hygiene in general.

Fully slatted:

|

Partially slatted:

|

Crate

|

|

Fully slatted pens increase ammonia emission as compared to partly slatted pens, but they are easier to clean. Partly slatted pens are most commonly used in Denmark due to the fact that frequency of injuries is lower, temperature and ammonia emission are easier to control than in fully slatted ones.

It should be noted that raised flooring in the sow zone has not been documented to prevent piglet crushing or improve pen output.

Lack of water is the first limiting factor for a high milk production. Therefore, the sow trough should be provided with a high yielding water nipple (10-13 litre/min). Low water yield from water nipples is one of the most common technology failures in farrowing units.

Piglets should also have access to a water nipple or small water bowl. But it is important to be aware of the water hygiene. Since piglets do not activate the water nipple the first couple of weeks after birth – old water should be removed through the water nipple before they start using it.

The sow trough should be shaped to accommodate the sow’s anatomy (head) and eating motions. Generally, it should have a volume of at least 20 litres. The trough design must accommodate easy cleaning without any blind corners or sharp edges that may injure the sow.