Introduction

The primary objective of the weaner and finishing unit is to provide a comfortable environment, which provides optimal conditions for a high growth rate and a feed conversion rate. Compared to natural conditions weaning under practical conditions is characterized by sudden separation from the mother at an early stage of age, complete change of diet and feeding method, complete change of environment and con-specifics. Moreover, the pig is exposed to handling and in some cases transport to another location. Finally, the pig’s ability to learn how to access food and water is challenged as well. Each of these changes is stressful events, which imply that the first few weeks post-weaning are particularly critical for the newly weaned pig.

Weaning unit – considerations

The weaning unit should be designed for all in all out management to allow cleaning and disinfection between batches and close control of the environment.

The number of weaner rooms depends on the projected average daily gain and expected live weight when pigs are leaving the unit again for sale or transfer to the finishing unit. In Spain pigs are transferred or sold at a weight of around 20 kg, which is somewhat lower than in northern Europe where the normal weight at transfer is 30 kg. The difference in weight at transfer affects design as shown in tables below.

Table 1. Effect of transfer weight on design criteria (start weight = 7 kg)

| Weight at transfer | |||

|---|---|---|---|

| 20 kg | 30 kg | ||

| Daily gain, g | 350 | 450 | |

| Days in unit | 39 | 53 | |

| Days for cleaning | 3 | 3 | |

| Space per pig, m2 | 0.25 | 0.35 | |

| Ventilation, m3/hr* | 25-38 | 45-68 | |

| Relative humidity, % | 50-70 | 50-70 | |

*Ventilation rate depends on climate – the lowest rate should be applied in a temperate climate like the Danish – while the rate should be increased in a warmer one such as the Spanish.

Environment and design

Pioneering research during the last three decades regarding pigs’ heat balance, heat production and heat demand has provided important guidelines for design of weaning facilities. Thus, it is well-known that the young pig is extremely sensitive to cold and drafts. Thus, the temperature at the time of weaning should be around 30º C. The design of the unit may accommodate the pigs’ heat demand in several ways. The most common design comprises the so-called hot nursery, which comprises a heated room with fully slatted pens with automatically controlled ventilation and heat (Figure 1).

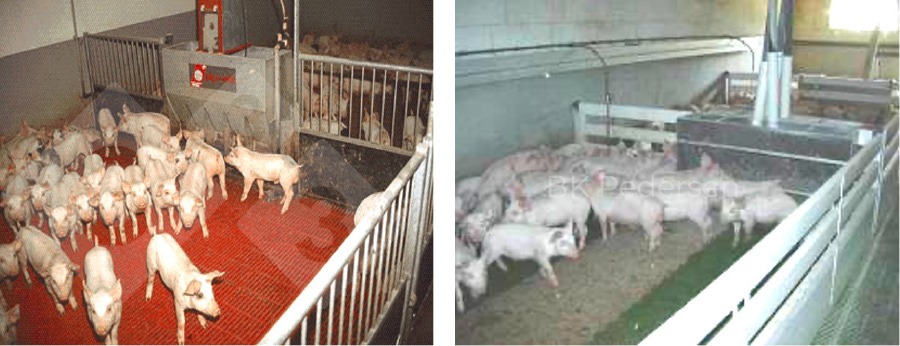

| Figure 1. Typical hot nursery pen with fully slatted flooring and room heat. | Figure 2. Hot nursery with partially slatted flooring and floor heating. |

A variety of this design is a system with supplementary floor heating in panels integrated in the flooring system (Figure 2). For both systems energy consumption is high due to the fact that the entire room must be heated to reach a temperature of 30º C, which is then gradually decreased to 20º C before pigs are leaving the unit.

However, a newer design (Figure 3), which is now used exclusively in Denmark and other Nordic countries, is the so-called two-climate system, which comprises a partially slatted pen with a covered lying area. The floor below the cover is heated with hot water pipes for the first couple of weeks after weaning. The heat is then turned off and the pigs’ own heat production is sufficient to keep the room below the cover warm. The cover may be lifted up during the last couple of weeks when heat demand is less. Since room temperature may be reduced to 24º C at weaning energy consumption is generally 50% lower than in a hot nursery. The effect of the cover is an increase in temperature of +6º C. Thus, below the cover temperature is 30º C while room temperature at start is 24º C. Moreover, this design provides pigs with more choices and a more varied environment than a fully slatted pen and therefore, it is considered more welfare friendly.

Figure 3. Two climate pen with partially slatted flooring and floor heating.

Pen design

Danish trials indicate that pen shape should be rectangular with a 2:1 length:width ratio, which accommodates activities such as resting, eating, defecating as well as social activities.

Trials have shown that a group size of 20-25 pigs per pen is ideal and it also coincides with the capacity of most feeders on the market. An extra water source apart from that supplied via the feeder should be provided.

Foot lesions are more likely to occur with small slat widths and large slot widths. Plastic flooring works well in fully slatted accommodations, but pigs should have access to a rougher surface such as concrete when they reach a weight of 20 kg to avoid long claws and claw lesions. In two climate pens – the slatted flooring should be cast iron 14/14 mm, which provides the best hygiene.