We know how important it is to attain maximum feed consumption by the sows during the lactation period. This will have an influence on the weight of piglets and, above all, will guarantee the future, as breeders, of the weaned sows. On the other hand, there still are many farms that waste a lot of feed in the farrowing quarters.

The devices that we normally use to give feed to the sows (hoppers or feeders) will condition our ability for attaining maximum feed intakes. We will have to adapt the feeding management according to each device in order to make the most of their strong points and try to correct their weak points.

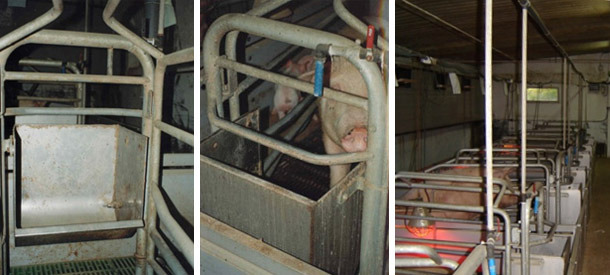

Hoppers

When we say that our goal is to attain maximum feed consumptions we can reach the quick conclusion that the best solution is to set up a hopper so the sow eats the amount of feed it wishes to and whenever it wants to do it. The hopper guarantees ad libitum consumption at all times, and the sows will be very calm regardless of the time when we enter the farrowing quarters.

Many technicians (us included) consider convenient to stick to the rationed feeding before the farrowing and to increase the ration progressively until reaching the maximum intake. We can solve this by setting up a telescopic pipe in the downspout of the feeder in order to attain different filling levels of the hopper, or even by setting up a dispenser in the downspout that then unloads the feed in the hopper.

Photo 1. Hopper that is regulated with a blade gate and that has a bowl. This system for regulating the falling of the feed is not very accurate.

|

Photo 2. Hopper with a fall mechanism. The regulation is more accurate than with the previous system. Bowl for providing water. |

We could think that delivering feed when we have hoppers is just a question of starting up the feeder so it fills all them up. Nevertheless, we must not forget that before filling them up we should check them in order to detect those sows that do not eat much or have stopped eating. Appetite is our main "tool" for detecting sows with problems. Nevertheless, when we use hoppers we normally have a less accurate control of the intake of each of our sows.

The design of the majority of the hoppers also complicates their cleaning when foul feed accumulates on the dish. Also, we must not forget that the sows housed in stalls may show stererotypies, and the continuous tampering with the mechanisms that regulate the falling of the feed can entail an increase of the feed waste. We must be very careful with the regulation of these mechanisms and be very attentive with regard to the presence of feed on the floor or the pit.

Normally, the use of hoppers also entails that the water supply will be apart from that of the feed supply. We think that the typical bowl with a nipple drinker can, due to its size and flow, affect the "comfort" with which the sow drinks and also affect, indirectly, the water intake.

Feeder

We associate the feeder with a certain number of meals per day in which we decide the amount of feed provided (we establish a feeding curve). Normally, the feeder has a nipple drinker and the sow eats wet feed (if the sows eat wet feed they normally attain higher intakes). From this, we can see that the feeders imply a higher dedication:

- When the time of the meal comes we unload the feed dispensers. We can automate some or all of these.

- According to the amount eaten by the sows we will increase (or not) the ration depending on the established curve.

- If any sow has lost her appetite it is convenient to remove the surplus feed to avoid that it becomes spoilt in the feeder. We will have to adjust that sow's feeding curve.

Photo 3. Big feeder with a high flow nipple drinker (7 litres/min). Drainage hole at the side for keeping the water at a certain level.

This higher dedication also entails a better knowledge of the intake level of each animal and also a more thorough monitoring of their general condition (every day we will watch if the sows get up to eat, if they show some kind of lameness, etc.).

Photo 4. Hand-feeding in very big feeders. The sow has a drinker with a medium flow available, but we have a tap in each place to add water when the time of the meals come or whenever we wish to.

The size of the feeder is important. Abundant feed rations mixed with water need big feeders (especially in those systems with a liquid feeding).

Photo 5. High flow nipple drinker in a small feeder. When we give feed we have a high waste.

A good feeder can also help us to attain a high water intake. In order for the sow to drink a lot we have to make things easy for her. A big feeder together with devices that supply a high flow of water guarantee that the feeder always has a good level of water. In this case the sow will be able to drink high volumes of water without difficulty.

Photo 6. Feeder with level valve. The sow has a good volume of water available at all times in the feeder without having to make the effort of obtaining it from a nipple drinker.

When there is an excessive amount of water in the feeders we must remove it before giving the meals in order to avoid feed waste. This can be due to stereotypies, but it happens, above all, when the sows feel hot in summer. In these cases we must improve the thermal comfort of the sow (refrigeration systems). A drainage hole that will determine the maximum level of water can also be present in the feeder.

In some cases we have seen "mixed" solutions: dispensers that instead of unloading the feed in a feeder they do so in a hopper, dispensers with a pulsation device that unload the feed in a feeder…

It is convenient to choose well the device and the management that we implement, because:

- High intakes are a guarantee of good results.

- The feed and the workforce represent an important percentage of the production costs.