Systems and mechanisms for feeding lactating sows have changed as technology has modernized swine farms.

In the first article we discussed more traditional systems (hand-feeding, dispensers, and hoppers).

In this article we will look at the systems that have been implemented in recent years. These systems have the goal of:

- Simplifying manual labor

- Achieving "true" ad libitum feeding.

- Avoiding that the human factor is what decides if a sow eats more or not.

The Feeding Ball

There are various designs of feeders with dosing devices of different types (ball, swivel, etc) paired with dispensers.

Although the most well known system is the feeding ball, different other companies have similar designs.

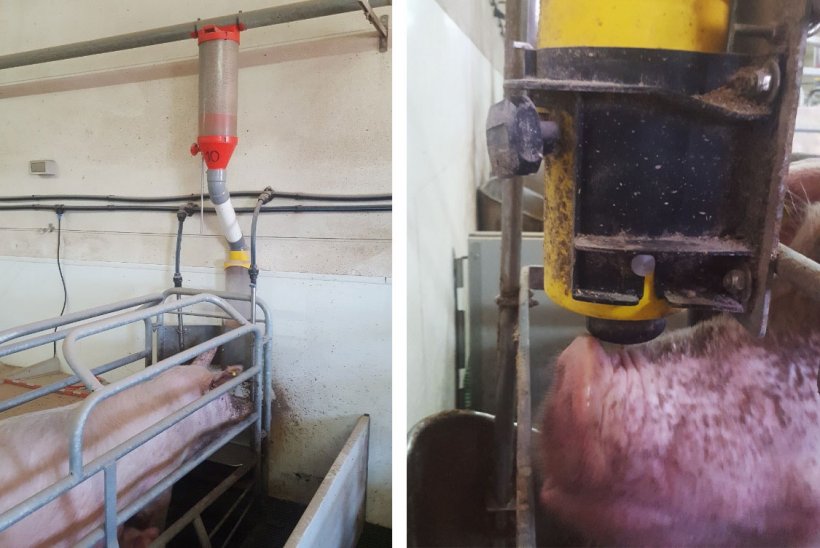

Figure 1. This feeding system consists of a dispenser, a fairly long connection tube, a device with the hopper and a ball mechanism

This feeding system allows the dispenser to be used before farrowing and for the first few days post farrowing. In this way we control the amount of feed given, limiting the amount at first and then progressively increasing it until day 7 or 10 of lactation.

After this point, the dispenser is set to the maximum amount, allowing the hopper to fill and the sow decides how much to eat.

System Advantages :

- Allows a controlled intake but also a progressive feed increase at the start of lactation and, as lactation continues, the system allows ad libitum feeding.

- The hopper is physically separate from the trough so that the feed stays fresh, clean, and dry before the sow makes it fall in the trough.

- Allows the sow to eat at other times of the day apart from when the automatic system is activated. This is very helpful during hot seasons, allowing the sow to eat during the cooler hours (in the evening), and in a way this can reduce the drop in feed intake that often happens with these hotter seasons.

Keep in mind:

- With this system, a sow can consume a lot of feed at once (up to 5 or 6 kg). We run the risk of increasing deaths due to stomach torsion or enterotoxemias associated with excessive feed intake. Especially when the transition from controlled to ad libitum feeding is very abrupt, or the farm is inconsistent in feeding (for example if a meal is skipped during weekends).

- A mechanism should be in place to prevent feed from falling too easily when a sow has the tendency to play with the feed instead of eating it.

- In some cases if a sow doesn't have very many piglets or doesn't produce much milk, the amount of feed she ingests may be excessive, even causing her to get fat during lactation which is not beneficial to her coming into heat well.

Electronic Systems for Dry Feeding

In the last few years electronic systems have been used in which feeding is controlled by entering a feeding curve into a software program.

In a way, these systems mimic the way liquid feeding works. One or more feed curves are determined and each sow in lactation is assigned to a feeding curve.

As the lactation progresses, the sow receives more feed according to the assigned feeding curve.

Photo 2. Electronic dry feeding system

System Advantages:

- Allows the daily allowance to be distributed in several different meals, making it easier to increase the total feed intake and even allows evening feeding during hot seasons.

- Different feed curves can be created according to the needs of the animals (for first parity sows or multiparous sows, for example)

- Reduces feed waste by distributing each meal in distinct portions that the sow herself can self-administer using a switch (photo 3).

- From the computer we can modify the feed curves, analyze the individual consumption of the sows, etc.

Foto 3. The majority of these systems drop the ration in servings of a few grams at a time. To avoid feed waste, there is an initial drop of feed which serves as a "call to eat," but more feed doesn't drop if the sow doesn't hit the dispenser switch.

Keep in mind:

- This system costs more than the others.

- Trained staff is needed, familiar with the use of computers.

- We can't ever do completely without "human supervision" to manage feeding.

Liquid Feeding

Widely used in European countries, this system allows sows to be fed on feed curves.

Its biggest advantage is the economic one, since the system allows the use of by-products reducing the feed price, although the greatest advantage is obtained in the finishing and not in the lactation phase.

Another advantage is that by supplying diluted feed, the sow also drinks a lot of water while she eats.

Older systems drop the entire feed ration regardless of whether the sow has eaten her previous meal or not. In any case, with these systems supervision and modification of the curve were needed to avoid feed waste.

More modern systems incorporate a sensor to measure level (photo 4). Excellent feed intakes can be achieved with well-managed liquid feeding, but it requires a high initial investment, excellent system management, and careful hygiene and cleaning. of the system.

Photo 4. With the level sensor, the more feed is not dispensed if the sow has not finished her previous meal.

New systems also often require changes in husbandry and changes in the way the animals are observed.

With hand feeding or with a dispenser, farrowing staff is present when the sow eats so it is very easy to see if a sow stands to eat or not. If she is not, it is easy to find out the reason why she isn't eating and act accordingly.

With many of the new systems, the sows eat when staff is not present, meaning we must change how we control feeding: look if the volumetric dispenser that holds the feed has gone down as expected, use relevant reports from the computer, observe the sows more carefully, etc.

Today we have various different options to feed sows in lactation. No system is perfect; all come with their own advantages and downsides.

Each farm should think about which system would work best, keeping in mind the farm's working conditions, genetics, and employees.