Since the majority of the current genetic lines are very lean and have a high prolificacy and milk yield, the management of feed, especially during the lactation stage, has become a key factor. The more the sows eat in the farrowing room, the more milk they produce and the more their piglets grow. Apart from the quality of the piglet, the future of the sow in the following reproductive cycle is at stake. The sows with a less endangered body condition and metabolic state show a better return to oestrus (lowering of the weaning-to-oestrus interval), ovulation and maintenance of the pregnancy (lower embryonic death). This turns into a better fertility, prolificacy, and a lower number of culled sows. In order to maximise feed intake it is important to split the number of meals, offering many daily portions of small amounts of feed. On the one hand we attain a better digestibility and a higher freshness of the feed, and on the other hand a lower waste of feed, because if a sow reduces its intake in a meal we will have to remove a lower amount of feed from it.

When we deliver the feed manually and we wish to give the sow several daily meals divided homogeneously, the first limiting factor is the length of the workday. Along the years, alternatives have been sought that allow offering feed during times in which there is no staff on the farm (even during the night), apart from reducing the time dedicated to its supply.

Free-access troughs

The simplest system is the free-access trough. The sow eats at libitum, but with a limit (the amount of feed that we introduce in the trough). The concept of the trough is good, but in practice its regulation is not easy, and it is much more difficult to remove the feed that has not been eaten and has become spoilt, so if they are not very well managed, more feed will become spoilt and feed intake may become even lower than if we use conventional troughs.

Slow flow with activation system

It is another of the existing options in the market devised for correcting the shortcomings of the free-access trough. It is a slow-flow feed dispenser. The sows hit a ball that has the mechanism for activating the flow of feed. In this way feed waste is reduced.

Dispensers with a timer

An option for dividing the number of feeds is attaching a timer to the classical automatic feeding system (with dispensers). Turnstiles similar to those used in the windows and controlled with a timer are in charge of pulling the towropes so the feed container opens. In this way we can programme the schedule and the amount of meals we wish to give. We can also programme the water supply in a similar way.

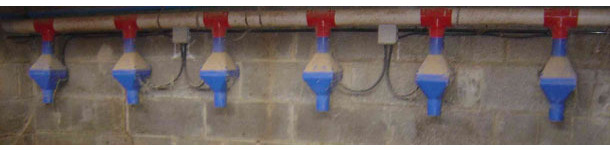

Slow flow with electronic regulator

A slow flow system with an electronic regulator for each space in the farrowing quarters allows the programming of several meals a day with the amount we wish for each sow. It does not allow to regulate a feeding curve automatically, so the regulator will have to be modified manually. It is more common to use it in pregnant sows' pens, but it has also been installed in some farrowing quarters.

Liquid feeding

Liquid feeding also allows the programming, through a computer, of the number of daily meals and, in this case, of the feed intake curve. Several feeding curves and meals can be established for certain groups of sows (for example according to the parity number or the number of piglets), but the treatment can also be customized for each sow, increasing or reducing the percentage of the ration in the proportion we wish (left photograph).

Computerized individual electronic regulator

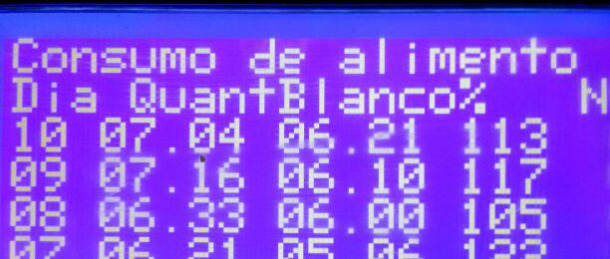

The most novel and sophisticated systems allow a customized feeding regulated through a computer and individual electronic regulators. They are more expensive systems, but that can offer a relatively quick return if they improve intake and reduce feed losses significantly. Apart from reducing the time needed for the supply of feed, it also reduces the time spent for controlling the feeding of the sows, because the computer and the individual regulator for each sow warn us, in real time, about those sows with intakes that are lower than expected, allowing for their quick identification. With these systems, the sow eats when it wishes to, because the feed supply is continuous up to an adjustable limit. The parameters can be modified through each sow's regulator or through the central computer. The sows obtain their ration when they push an electronic shaker, obtaining a small amount of feed. This increases intake and reduces feed losses, because the sow must empty the trough in order to activate the electronic shaker, so no new feed will fall if the sow has not eaten up the previous feed. Another interesting thing is that all the generated information is stored in the computer for its subsequent analysis.

As we can see, there are several options: from the simplest systems to the most complex and automated ones. There are options that allow the sows to eat when they wish to (trough, slow flow with activation, computerized individual electronic regulator), whilst others allow to increase and split the number of daily meals (dispensers with a timer, slow flow with an electronic regulator, liquid feeding).

As we can see, there are several options: from the simplest systems to the most complex and automated ones. There are options that allow the sows to eat when they wish to (trough, slow flow with activation, computerized individual electronic regulator), whilst others allow to increase and split the number of daily meals (dispensers with a timer, slow flow with an electronic regulator, liquid feeding).