In high-density swine regions of North America, air filtration is playing an important role in the effort to maintain PRRS free commercial sow herds. After initial trials in Artificial Insemination (AI) centers, there are now more than 200,000 sows housed in filtered farms in the Midwest United States alone. Air filtration prevents infection or re-infection of farms via aerosol spread of the PRRS virus. It has been well demonstrated that this puts them at a much higher level of biosecurity. But…are we familiar with the system? Do we understand the nomenclature? The objective of this article is the review of the important technical data related to this new technology in farming and an analysis of the different strategies being increasingly implemented on commercial sow farms.

Important technical definitions:

- Bioaerosol: Biological, solid or liquid particles that stay suspended in the air or other gaseous environments. In general, they are between 0.4 and 0.7 microns. The PRRS virus, with a size of 0.050 - 0.065 microns, moves as a bioaerosol, surrounded by organic material, to distances of more than 9 km.

- Efficiency: Capacity of the filters to stop particles like dust, pollen, mold and bacteria. The more efficient the filter, the smaller the particles it can stop. The filter become more efficient over time, due to the fact that it can trap a larger percentage of smaller particles.

- Filter resistance: This is the effect that the filter has on air flow. When filter resistance is high, filter efficiency increases, but the total volume of air that can pass through the filter decreases. As a result, more filtered air inlets are needed. On the other hand, when filter resistance is low, filter efficiency decreases but the total volume of air that can pass through the filter is greater and fewer filters will be needed. Air flow volume is measured in m3/s.

Filter types and their classification:

- DOP test: System of filter classification (expressed in %) based on the efficiency of the filter in preventing air particle transmission. The air particles used are aerosol-dispersed “di-octyl phthalate” (DOP) drops with a 0.3 µm diameter.

- HEPA filters: Filter with a 99.97% DOP capacity. These are the most efficient but they offer increased resistance.

- MERV (Minimum Efficiency Reporting Value): Standard American system of filter efficiency classification which allows for the comparison of filters manufactured by different companies. The higher the MERV classification, the more efficient the filter is in the three testing ranges. (i.e. E1 (0,3 to 1 µm ), E2 (1 to 3 µm) and E3 (3 to 10 µm)). MERV classification is from 1 to 20 (least to most efficient).

- EU: Standard European system of filter efficiency classification system and is similar to the American MERV nomenclature. It has a range of 1-14.

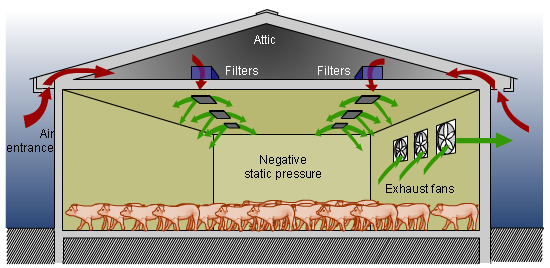

The most widely used ventilation system in North America is negative pressure ventilation. Farms use exhaust fans that draw the air from the animal space inside the barn to the outside area. They create negative static pressure that normally varies from 12.45 to 50 Pascals (0.05-0.2 inches of water). The higher the filter resistance, the higher the static pressure and the lower the volume of air that is permitted to pass through the barn. In order to achieve an adequate volume of filtered air when air volume turnover demand is high, we will need more filtered air inlet space. As always, static pressure monitoring is key to good swine barn ventilation.

Graph 1: Negative pressure ventilation system with air filtration of attic inlets.

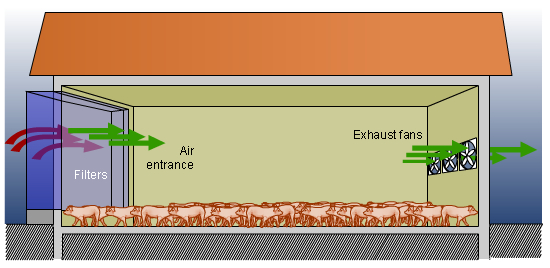

Graph 2: Negative pressure tunnel ventilation. Summer ventilation.

Graph 2: Negative pressure tunnel ventilation. Summer ventilation.

The filters most widely used on commercial sow farms in high-density swine areas (high risk of infection) are the MERV 14 or EU 6 (DOP 85-90%). These filters, technically, are characterized by allowing 0.43 m3/s of air per filter at a static pressure of 50 Pascals and offering a resistance of 20 Pascals at 0.3 m3/s. How can we calculate how many filters are necessary on a farm? Although all these numbers seem complicated, they are easy to understand when you know the ventilation needed for each type of production stage (lactation, gestation, weaning…) as well as total number of animals in the farm. The tech support department of companies that install filtration systems employs professionals that carry out the displacement process with these numbers based on each farm’s specific requirements. They take into account the number of animals, the necessary air volume, the type of filters, fanpower and total openings.

There is not a single combination or system that is ideal for all farms. Each filtration system is constructed individually, and the different combinations of filters, fans and openings have to take the following into consideration:

- Budget available for investment.

- Geographical location of the farm (high swine density and high risk of airborne infection vs. low density and less risk).

- Level of risk accepted by the owner (year round filtration vs. filtration only in winter).

- Production type (commercial farms, breeding stock, weaning, etc.).

On average, a farm of 3000 sows in a high-density area can have 1200 filters installed to ensure a correct functioning system. The cost:benefit of these farms is being evaluated by the Disease Eradication Center of the University of Minnesota.