Batch management is not new; it is a way of working that has been implemented on farms for almost 20 years.

Generally speaking, batch management has been implemented on small and medium-sized farms, mainly to optimize animal flows by working with larger groups of the same age and to optimize all-in/all-out management and indirectly to concentrate tasks and improve work distribution. However, in recent years and after the emergence of the latest highly virulent strains of PRRS, this way of working has also started to be implemented on larger farms to allow working with fewer and larger batches of animals of the same age and thus emptying certain farm facilities in their entirety, helping to control the disease by "forcing" a strict all-in/all-out and a good sanitary downtime between batches. The batch chosen in this case is undoubtedly the 5-week batch.

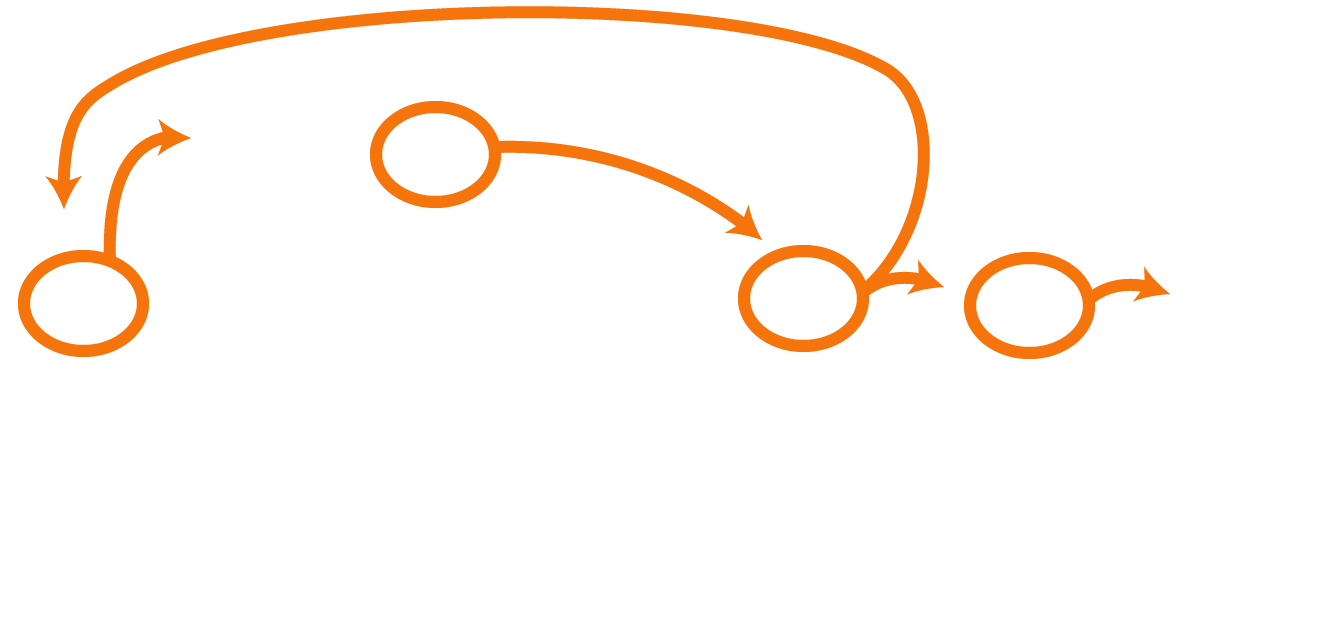

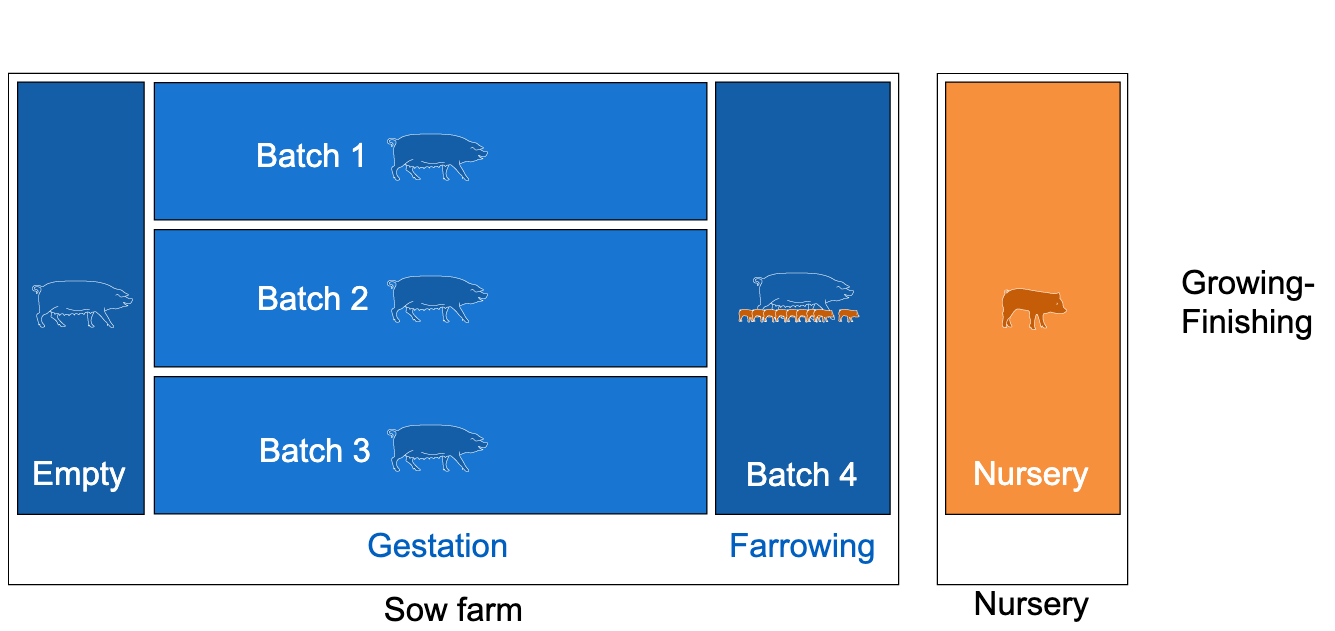

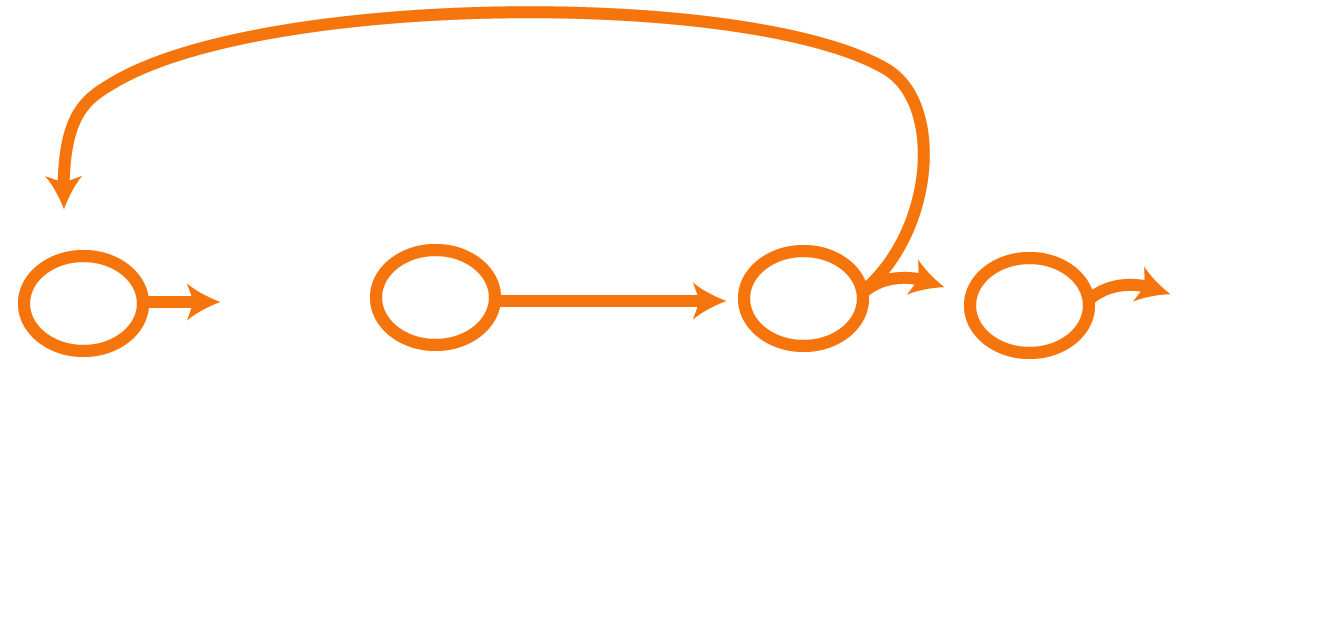

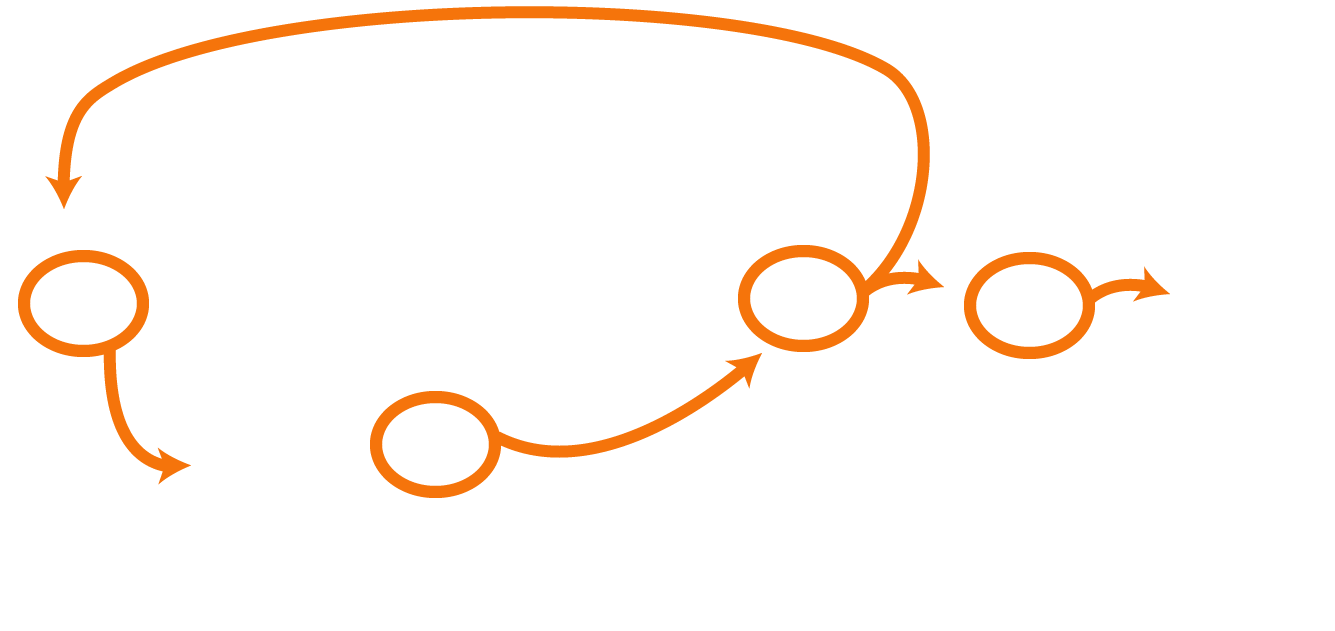

With a 5-week batch management system, we will have in theory:

- 4 batches of sows on the sow farm

- 1 in the farrowing area.

- 3 in gestation → Although in this phase we theoretically need the open space equivalent of one batch to be able to move sows.

- 1 batch of piglets on the nursery farm. There could be two batches as long as we have the capacity to keep the animals up to nine weeks, but the case of having two batches in the same facility would not be justified because we would lose the sanitary benefit, something we will discuss later.

To know more about how a 5-week batch or other batches work you can use the Batch management simulator from Pig333.

In practice, the reality is that on a 3,000-sow farm, we will never have 750 empty spaces in gestation to move animals, but as we clean farrowing rooms, we will move animals and free up gestation space.

To address the last point and many other aspects of 5-week batch management, we would like to talk to Luis Sanjoaquín and draw on his experience in implementing this system to help us answer some of our questions on the subject:

1. Why are we considering moving to 5-week batches, especially on large farms?

Currently, we do this exclusively to improve the health of our animal flows and reduce the problems caused by age mixing and outbreaks of virulent strains, primarily PRRS, on farms.

2. What advantages can we gain?

|

Sanitary:

|

|

Logistical:

|

|

Management:

|

|

Team management:

|

3. What are the main challenges?

|

Management:

|

|

Sanitary:

|

|

Facilities:

|

|

Logistical:

|

|

Production:

|

Surely we have missed some advantages and challenges, but we have tried to share all the ones we have encountered in our experience working with these systems.

We will address some of them in more depth in future articles.