Feed manufacturing is not just about mixing essential nutrients, it also affects the health, safety, and welfare of animals and people, as well as the producer's commitment to profitability. All these elements must be taken into account when producing feed.

The following are some of the processes that often positively or negatively affect production efficiency, feed consumption, animal health, and above all, the profitability and economy of the farm:

Grinding

Grinding ingredients favors proper mixing, reduces the probability of particle segregation in meal preparations, and improves pellet quality. It optimizes animals' nutrient utilization due to the larger contact surface with digestive enzymes.

Particle size can be measured by the geometric mean diameter (GMD) and its standard deviation, which has an optimal value according to the category of animal. Too low a GMD (fine particles) increases the incidence of gastric ulcers, reduces feed consumption, and consequently reduces production efficiency; in extreme cases it can even lead to animal death.

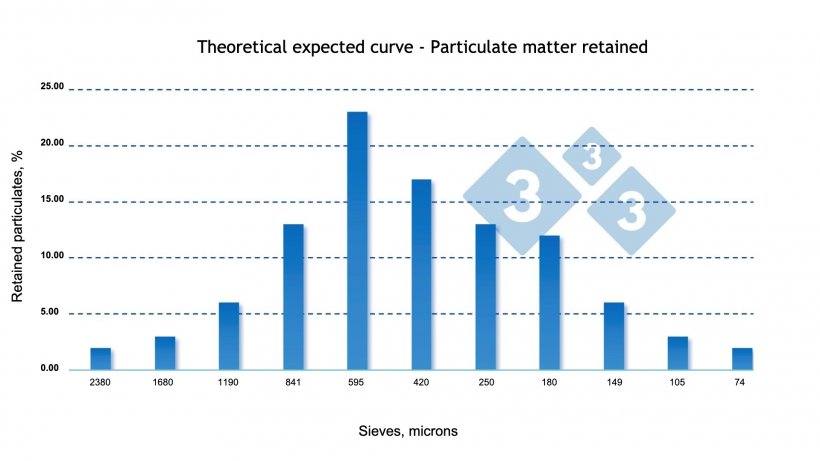

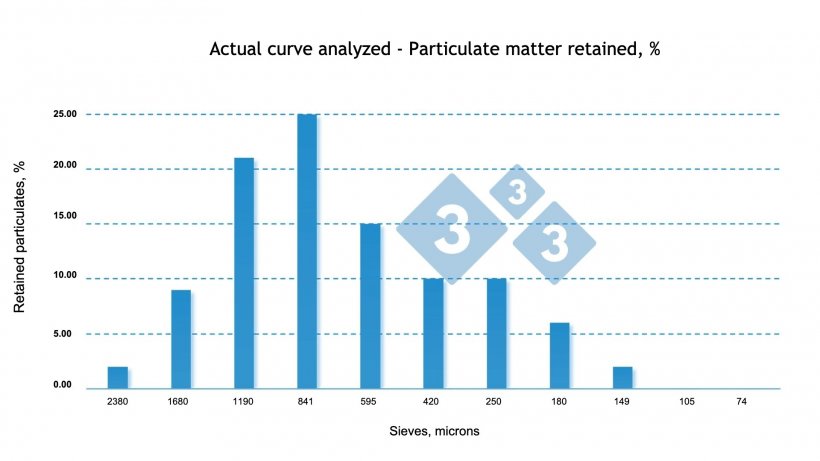

When checking the feeders it is common to find feed with extremely coarse and uneven particles or to find pieces of grain in the feces, evidencing that the animals were not able to digest the feed properly which has direct repercussions on the production efficiency of the farm. Figures 2 and 3 demonstrate an example of the difference between an ideal particle retention curve for growing pig rations versus an actual curve from a commercial farm.

Figure 2: Ideal particle retention curve in feed for growing pigs.

Figure 3: Actual feed particle retention curve of growing pigs from a commercial farm, in this feed there is a higher % of particles retained in the larger caliber sieves, evidencing that the ration contains coarser particles than expected for this category of animals.

Table 1: Table of recommendations of geometric mean diameter (GMD) in micrometers according to animal category.

| Type of animal | Geometric mean diameter (GMD) |

|---|---|

| Piglet | 400 μm - 500 μm |

| Growing/Finishing | 500 μm - 650 μm |

| Breeding sows | 500 μm - 600 μm |

Source: Neta, 2015; Zanotto, 1999; Penz, 1998.

Dosage

Correct dosage of ingredients is essential in order to meet the nutritional requirements of the animals, so it is imperative to know and respect the limits of acceptable deviations.

Generally in feed mills, the list of available ingredients is short and the main causes of intoxications, such as microminerals, are included in commercial premixes. Thus, the main risk is related to the lack of dosage of an ingredient.

A quite common example is seeing animals with bone development problems or fractures, caused by a failure in the dosing equipment or the operator forgetting to add the vitamin and mineral premix/ to the mixer; in addition, errors in dosing amino acids and drugs can reduce the production efficiency or compromise the health of the animals.

Cross-contamination

There are many critical points that can lead to cross-contamination, such as internal transport, silos, weighing hoppers, mills, mixers, pelletizers, tools, people, trucks, pests, etc.

A classic example would be the contamination of rations containing ionophores with pleuromutilin antibiotics such as tiamulin. The effects on animals can be devastating, with high mortality.

Another important point is the presence of pests such as pigeons and rats, which can contaminate feed with high Salmonella loads, causing serious enteric problems, mainly in young pigs.

Table 2: Main findings and causes of cross-contamination in feed mills.

| Type of cross-contamination | Practical examples | Main causes |

|---|---|---|

| Physical | Presence of foreign bodies in the feed (plastic, wood, etc.) |

|

| Presence of corn grains in the soybean meal or any contamination between raw materials |

|

|

| Chemical | Presence of drug residues above the permitted level in non-medicated feeds; Presence of monensin in feed that includes tiamulin in its formulation. |

|

| Presence of feeds with an erroneous nutritional profile with respect to their category; Presence of drugs in non-medicated feeds. |

|

|

| Microbiological | Microbiological count above the permitted level; Clinical cases of salmonellosis in piglets |

|

Storage

The way raw materials or feed are stored, as well as the tidiness and cleanliness of the warehouses, can determine the final quality of the products.

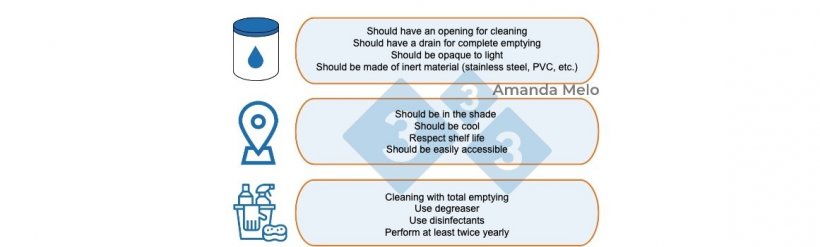

Vegetable oils or animal fats are commonly used in feed formulation, due to their high energy content. If stored incorrectly (long periods of exposure to high temperatures or sunlight, in inadequate and dirty containers, and without the regular use of antioxidants), fatty acid peroxidation and loss of activity of fat-soluble vitamins occur, which leads to a decrease in palatability, animals refusing to eat the feed, and low efficiency.

Figure 4: Recommendations for the proper storage of vegetable oils and animal fats.

Table 3. Main synthetic and natural antioxidants used in preserving raw materials, fats, and oils.

| Synthetic |

|

Butylated hydroxyanisole (BHA) |

| Butylated hydroxytoluene (BHT) |

| tert-Butylhydroquinone (TBHQ) |

| Propyl gallate (PG) |

| Natural |

| Tocopherols |

| Ascorbic acid |

*Consult the current legislation in your country

Mycotoxins can also be directly related to deficiencies in storage such as lack of rotation, high presence of damaged grains, insects, lack of aeration, and high temperatures. They cause various problems ranging from low feed intake or feed refusal, to clinical signs and death in extreme cases.

Table 4: Mycotoxins posing the highest risk to animal and human health

| Micotoxin | Fungi that produces it | Raw material |

|---|---|---|

| Aflatoxin | Aspergilus flavus, A. parasiticus. | Corn, peanuts, oilseeds, other cereals. |

| Fumonisins | Fusarium verticilioides, F proliferatum, Alternaria alternata f. sp. Lucopersici. | Corn, other cereals. |

| Zearalenone | Fusarium graminearum, F. culmorum, F.esquiseti. | Corn, barley, wheat, sorghum, rice, rye, soybeans. |

| Deoxinivalenol | Fusarium graminearum, F.culmorum. | Corn, barley, rye, oats, wheat. |

| T-2 mycotoxin | Fusarium sporotrichioides, Myrothecium, Phomopsis, etc. | Corn, wheat, other cereals. |

| Ochratoxin | Aspergillus ochraceous, A. carbonarius, Penicilium sp., Fusarium sp. | Corn, barley, coffee, rice, beans, wheat. |

Source: Adapted from Embrapa, 2015.

These are just some of the points of impact that feed manufacturing can have on the farm; it is essential to know the dynamics of each point to establish effective controls and thus prevent negative impacts.