5. Abortions without a specific cause.

Is one of the most frequent and more serious errors, since its impact on the analysis of abortions is very important. As a general rule, the first proven event must be always recorded (i.e., a sow that returns to heat because it's just had an abortion must be recorded as "abortion"; a sow that has an abortion due to an injury must be recorded as "injury / accident"; a sow with a negative diagnosis of gestation due to metritis must be recorded as "metritis", etc). This is particularly common after 40 days of gestation, when a period of remarkable darkness begins.

6. Sows culled without a cause or with a too generic cause.

Causes are too often recorded as "other causes" or "underachiever". A little effort invested in both standardizing the causes and then precisely recording the reason for each elimination, will allow us to obtain high quality information, which is quite unusual.

| Cause of death | |||||||||||

| No. | Weaned not serviced | Abortion | Barren | Pregnant | Gilt not serviced | ||||||

| No. | % | No. | % | No. | % | No. | % | No. | % | ||

| R00 reproductive problem | 19 | 3 | 15.88 | 0 | 0 | 15 | 78.9 | 1 | 5.3 | ||

| R03 Abortion | 1 | 0 | 0 | 0 | 1 | 100.0 | 0 | ||||

| X00 Other causes | 38 | 9 | 23.77 | 0 | 0 | 28 | 73.7 | 1 | 2.6 | ||

| Total | 58 | 12 | 20.7 | 0 | 0 | 44 | 75.9 | 2 | 3.4 | ||

Figure 3. Farm with a 66% of sales of sows without a recorded cause.

7. Pre-weaning mortality without dates and with confusing causes.

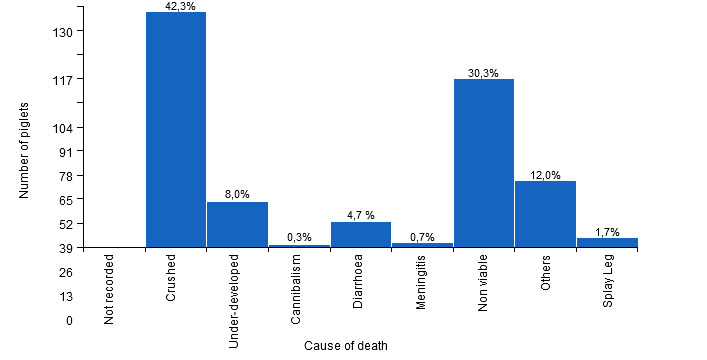

In most cases, the operator's impression when the veterinarian asks "What is the main cause of mortality in piglets and their age?" does not correspond to reality.

This is because some causes stand out more than others to the operators' eyes and, above all, because they quickly get used to what they see every day on the farm. When this happens, abnormal events fail to draw the workers' attention. It is therefore essential to build upon objective data in order to obtain objective information and make appropriate decisions.

Moreover, misconceptions were found in many cases, such as the inability to clearly differentiate between an "under-developed" animal and a "non-viable" one. The root causes are different: lack of milk and feeding problems during gestation, respectively. Therefore, there should never be older than 4-5 days "non-viables".

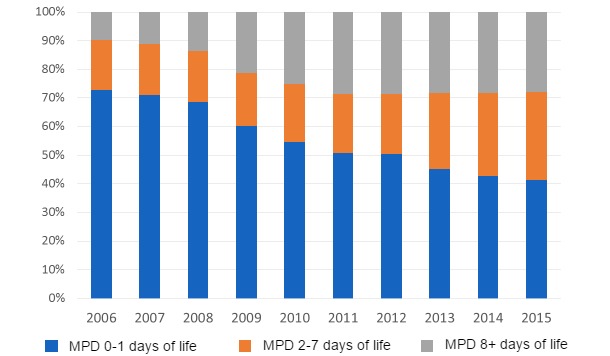

In order to determine the normal levels within each age group, the type of genetics present in the holding must also be taken into account. As Figure 4 shows, the distribution pattern has changed over the years with the increased presence of this type of genetics, decreasing peripartum mortality and moving to the next age group (70% in 2006, whereas in 2015 it was 41%.)

Figure 4. Evolution of the distribution of pre-weaning mortality (PWM) depending on the age at death in the last ten years.

Based on data from 3,102,130 services

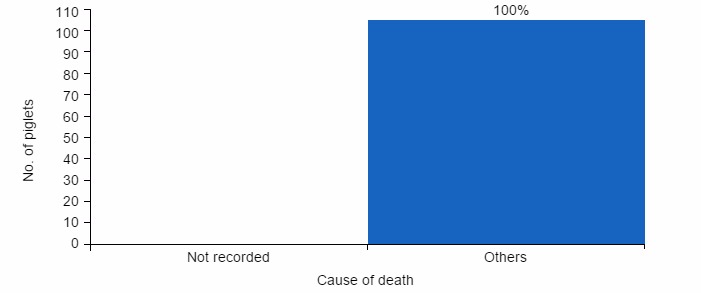

Figure 5. Pre-weaning mortality by cause of death. The graph shows a farm that records deaths incorrectly.

Figure 6. Pre-weaning mortality by cause of death. The graph shows a farm that records deaths correctly.

8. Inadequate processing of nurse sows.

Hyper-prolific genetics increasingly require more and higher-quality work in the farrowing unit, so failure to record this and ignoring its consequences (for better or worse) are both unacceptable for a professional producer. Obviously, a software that can properly process this kind of management (which is not easy and therefore not common) must be available in the first place.

When these data are available, they can be analysed for indicators such as the difference between weaned per litter and weaned per sow, parameter showing the efficiency of the use of nurse sows. The number of weaned / litter indicates the average size of a weaned litter, whereas the number of weaned / sow takes into account the real extra weaned piglets through the use of partial weanings or nurse sows.

| 09-Oct-15 to 29-Oct-15 |

30-Oct-15 to 19-Nov-15 |

20-Nov-15 to 10-Dec-15 |

11-Dec-15 to 31-Dec-15 |

Mean | |

| Sows completely weaned | 105 | 118 | 119 | 98 | 110 |

| Sows weaned | 17 | 14 | 28 | 15 | 18 |

| Sows weaned without a litter | 0 | 4 | 4 | 2 | 2 |

| Litters weaned | 126 | 142 | 139 | 106 | 128 |

| Use of a nurse sow | 21 | 28 | 24 | 10 | 21 |

| Weaned piglets | 1617 | 1733 | 1727 | 1248 | 1581 |

| (from partial weanings) | 52 | 0 | 0 | 0 | 13 |

| Average weaned/litter | 12.8 | 12.2 | 12.4 | 11.8 | 12.3 |

| (Less piglets from partial weanings) | 12.4 | 12.2 | 12.4 | 11.8 | 12.2 |

| Average weaned/sow | 15.4 | 14.7 | 14.5 | 12.7 | 14.4 |

| (Less piglets from partial weanings) | 14.9 | 14.7 | 14.5 | 12.7 | 14.3 |

Figure 7. Weaning parameters of a farm where nurse sows and partial weanings are recorded.

9. Ignoring treatments.

Hormone products (gonadotropins, altrenogest, prostaglandins, vetrabutine or oxytocin) are regularly used to adjust heats, synchronize, facilitate or speed up farrowings, but rarely recorded and processed in order to determine their impact on the variable that needs to be controlled (onset of heat, farrowing day, milk production, etc.) It is a remarkable mistake, since it limits decision-making ability in a critical area on the farm, both for its technical and economic impact.

| Date | Farrowing | Event | Details |

| 26-Oct-15 | Dead piglet | 1 crushed (4 days old) | |

| 31-Oct-15 | Transfer | 1 piglet to sow 242 | |

| 19-Nov-15 | Total weaning | 10 piglets (2 piglets less) (28 days) | |

| 18-Dec-15 | X1 1st service | Semen: PIETRAIN (PM) (29 days) | |

| 18-Dec-15 | X2 Service | Semen: PIETRAIN (AM) | |

| 19-Dec-15 | X3 Service | Semen: PIETRAIN (AM) | |

| 20-Dec-15 | X4 Service | Semen: PIETRAIN (AM) | |

| 11-Apr-16 | 8 | Farrowing | 6 born alive, 2 stillbirths, 0 mummified (115 days) |

| 11-Apr-16 | Adoption | 2 piglets from 136 | |

| 11-Apr-16 | Adoption | 2 piglets from 348 | |

| 15-Apr-16 | Transfer | 1 piglet to 343 | |

| 05-May-16 | Total weaning | 9 piglets (24 days) | |

| 16-May-16 | X1 1st service | Semen: PIETRAIN (PM) (11 days) | |

| 16-May-16 | X2 Service | Semen: PIETRAIN (AM) | |

| 16-May-16 | Mark | G-PG 600 | |

| 17-May-16 | X3 Service | Semen: PIETRAIN (AM) |

Figure 8. Recorded history of a sow treated with PG 600.

All errors described are very common in most farms. The accumulation of such errors hinders the work of technical and farm managers, as reports or worklists are implemented with incorrect or unreal data.

We recommend to correct two errors per month which, within a gestation period, will allow you to considerably increase your ability to improve your production.