The livestock industry's rapid growth has increased pressure on natural resources. The swine industry also contributes to greenhouse gas (GHG) emissions. Its annual global emissions are estimated at around 700 million tons of CO₂ equivalent, a considerable figure. However, when compared to other livestock sectors, it is lower. For instance beef industry is responsible for approximately 5.8% of global greenhouse gas emissions, generating more than 1.3 billion tons of CO₂ equivalent per year. The main source of these emissions comes from methane released during digestion (enteric fermentation) and manure management. This places cattle as one of the largest contributors within livestock farming, with double the emissions of swine.

If we extend the comparison to non-livestock industries, such as commercial aviation, we find an interesting outlook. In 2019, aviation emitted around 918 million tons of CO₂, representing approximately 2.5% of global CO₂ emissions from fossil fuel use. This level of emissions is comparable to those of the swine industry, underscoring the environmental impact of both industries.

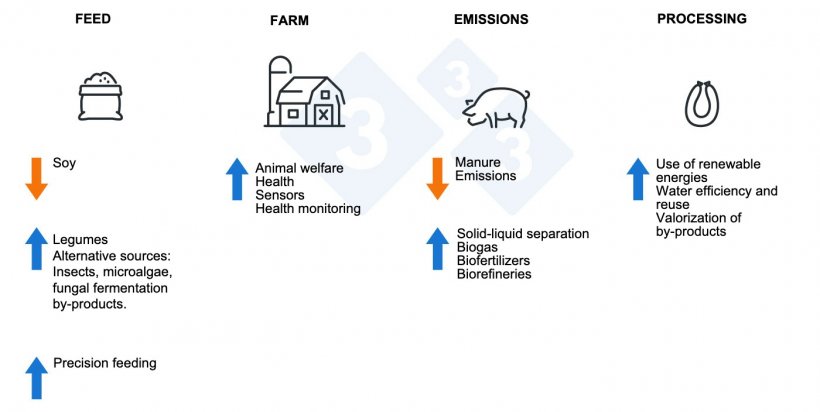

While the pig sector has been working for years on ways to become more sustainable, let us now examine all the points along the value chain where interventions can be made to reduce these emissions and advance sustainability.

How to make the swine industry more sustainable?

More sustainable animal feeding

Ninety percent of the feed tends to be comprised of soybeans and cereals. Cereals such as wheat, barley, and corn are widely produced in the European Union, but conditions are not optimal for soybean production and they must be imported. Imported soybeans may be associated with deforestation processes prior to their production, having a significant environmental impact. The felling of trees leads to a reduction in sequestered CO2, which contributes to global warming and reduced available oxygen. That is why it is important, although not completely mandatory by the EU, that farms buy soybeans with a sustainability certificate that guarantees that no deforestation has taken place to produce them.

Soybeans are the best protein source known so far for feed production because they have a very good amino acid profile. However, protein sources such as legumes (peas or beans) can be increased. Countries including France and Germany are already investigating how to grow more protein crops. Also under study is how to obtain protein from alternative sources such as microalgae, insects, or that which could be obtained from the fermentation of fungi.

On the other hand, improving pig feeding efficiency and precision (offering the required feed at each growth period and matching the protein needs with the nutritional intake required) reduces the amount of nitrogen in the slurry. Improving feeding results in less manure and more sustainable manure.

Emission reduction and manure treatment

Manure management is one of the key points for improving the sustainability of the meat industry's production process. A series of slurry treatment technologies are available to farmers to improve slurry management. The main limitation is the high water content which makes transporting it very costly. Currently, the most widely used technology is solid-liquid separation, which allows a solid fraction to be obtained, with a high concentration of nutrients and organic matter, which should be exported to areas with a demand for nutrients. On the other hand, the liquid fraction obtained should be applied in the nearby area.

The level of implementation of new treatment technologies to improve slurry management is still relatively low due to economic, technical, and legal aspects. Therefore, research is working on new technologies and strategies to produce new high-value-added products, mainly biofertilizers from manure, which help to make the whole process more sustainable. Many of these strategies are based on the design of biorefineries, which are facilities that combine different technologies to treat manure on a small scale.

One of the main value-added products that can be obtained from manure is biogas. Producing it opens the door to new forms of energy recovery within the farm itself, or exporting it and generating new income that can help make the industry more sustainable. However, it is important not to lose sight of the fact that biogas production generates a new by-product, digestate, which we must manage efficiently. Countries such as Denmark already have manure management and biogas production systems in place, with some 50 plants, including some of the most significant in Europe.

Improved animal welfare and farm typology

Pig farms have undergone significant structural transformations, such as adopting cage-free systems. In addition, enrichment materials, such as straw, wood, or toys, have been incorporated, allowing pigs to express natural behaviors such as exploring and interacting with their environment. At the same time, automation and advanced technologies, such as sensors to monitor animal health, have optimized farm efficiency.

Sweden and the Netherlands are known for strict enforcement of animal welfare standards, including prohibiting controversial practices such as tail docking with a focus on improving environmental conditions in the pens to reduce stress and encourage natural behaviors.

A more sustainable processing stage

Certain energy and emission reduction regulations must be complied with in the slaughter and processing phases. One way to achieve this is to use renewable energy, improve the energy efficiency of the facilities, or reduce water usage through precision use and good treatment so that it can be reused. The application of advanced technologies for treating wastewater from the agri-food industry allows water with potential for reuse to be obtained and thus promotes the circularity of a fundamental resource. The Technological Centre in Biodiversity, Ecology and Environmental and Food Technology (CT BETA) of the University of Vic - Central University of Catalonia (UVic-UCC) has worked on an advisory guide to promote the recovery and reuse of water in meat processing, based on the results and conclusions obtained in research and knowledge transfer projects.

The management of slaughterhouse by-products must also be improved, determining the best way to valorize each by-product or organic waste obtained (meat scraps, blood, bones, skin, sewage sludge). Some can be used as raw materials in human or animal food, others for agronomic or energy recovery, and some products should be disposed of.

Tools that enable us to be more efficient

To help the swine industry achieve higher sustainability standards, the CT BETA of UVic-UCC, with the collaboration of the clusters INNOVACC and I+Porc, the GSP Association, and 333Corporate, have developed an innovative tool designed to calculate the environmental footprint along the swine industry's entire value chain: PigPEF.

Conclusions

In conclusion, to make the swine industry more sustainable, it is essential to improve efficiency in the use of resources, properly manage manure, and adopt local and sustainable protein sources. Advancing animal welfare is also key, promoting more ethical systems and better conditions for pigs. Implementing innovative technologies at all stages of the process, from farms to processing, can reduce the environmental impact and improve the industry's sustainability.