Many farmers choose to make their own ramps to load their animals; either to save money or because they need something custom-built. There are all kinds: wooden, iron, or steel, mixed, with or without wheels, with or without a height adjustment mechanism, etc.

However, a ramp is not a trivial tool; loading pigs on the truck is a strenuous job that requires experience. It is important to understand pig behavior and to create an "attractive" route that first encourages them to approach the ramp and then to go up it. The pigs must be guided along a single path that prevents dangerous crowding. When they reach the ramp, they often get stuck, either because of the novelty (different flooring, outdoor environment, light/darkness, etc.) or because of the slope.

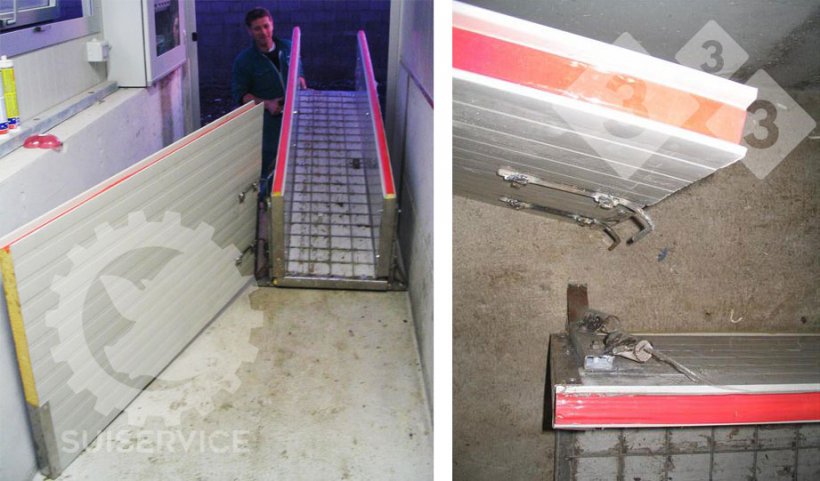

Here we present an "emergency" ramp that this farmer fabricated using leftover insulation panels from the construction of the nursery. Three panels (the side walls and floor) are bolted to three U-shaped frames that support the structure.

Three insulating panels (the kind used in barns) are bolted to three U-shaped iron frames that act as supports for the structure. Since these panels are lightweight (consisting of two metal sheets with insulation in between), they give sturdiness and lightness to the structure, which can be easily moved by a single person.

Electrowelded wire mesh has been fixed to the base which serves to keep the animals' feet from slipping.

It is very important for the piglets to have a firm grip on their feet when going up the ramp. In this case, an "anti-slip" electrowelded wire mesh has been attached to the base panel.

These panels are so light that the ramp is easily transportable, even without wheels. Naturally, such a structure can only be used to load piglets (and not large animals). In this case, it is used to load piglets that weigh less than 30 kg. In addition, due to its limited length, it can only be used from an already-elevated aisle.

The ramp is placed in the service aisle of the barn, ready for loading, with a movable panel that redirects the piglets. The aisle is elevated (50-60 cm) with respect to the outside surface, so a relatively short ramp is sufficient.

Detail of the coupling system of the panel redirecting to the ramp: two iron rods conveniently bent and fixed to the panel are inserted into two corresponding pipes fixed to the left panel of the ramp. The mobility of the coupling allows vertical movement of the ramp and horizontal movement of the panel without the risk of it coming unhooked.

In addition, a fourth panel with a simple ramp attachment system is used that acts as a funnel to the loading ramp. It's not perfect, but it works!