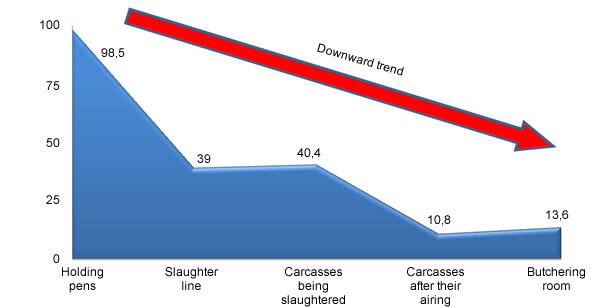

In the previous article, we have introduced the importance of the abattoir in the concept “from the farm to the table” with respect to the control of salmonellosis. In the abattoir there are three distinct physical areas: the lairage pens, the slaughter line and, lastly, the butchering room (if it is, physically, in the abattoir). In a study carried out by our investigation group in various abattoirs, we checked that the contamination in the abattoir due to salmonellas decreases from the lairage pens to the butchering room, as it can be seen in the figure (figure 1). Also, the prevalence found in the carcasses seems to be related to the contamination of the room in which the samples are taken. In this article we will try to analyze which are the critical contamination points in the abattoir, as well as the measures that can be taken with regard to them.

Mean prevalence at each point

Figura 1. Prevalences attributable to different areas of the abattoir

The lairage pens: a source of salmonellas

The majority of the studies carried out conclude that the lairage pens represent a very important source of infection for the pigs housed in them. The contamination of the environment by the infected pigs contributes to the spreading of the infection to the healthy pigs. Also, the cleaning and disinfection protocols are very ineffective. The Salmonella strains found in the lairage pens have been frequently related to the strains present in the carcasses. Amongst the possibilities of contamination in the lairage pens there is, of course, a great influence of the time that the pigs remain in these pens from the moment of the unloading from the lorries until their slaughter.

What happens in the slaughter line ?

As it can be seen in the figure (figure 2), in the dirty area of the slaughter line there are variations with respect to the amount of enterobacteria (amongst them Salmonellas) found in the surface of the carcass. The carcasses enter the slaughter line contaminated, very frequently, by the salmonellas present in the faeces. The singeing and scalding processes, always that the temperature is higher than 63°C, reduce or even eliminate the enterobacteria present on the surface of the carcass, whilst the dehairing machines favour the recontamination of the carcasses, because in the dehairing machines there is an accumulation of organic matter with salmonellas that are then scattered.

Prevalencia en canales durante el sacrificio

Figura 2. Evolution of the prevalence in the carcasses during their slaughter operations.

Once the carcass arrives to the clean area, its contamination will depend on the characteristics of the slaughter line. Generally speaking, it can be said that the more automatized a slaughter line is, the lower the risk of contamination of the surface of the carcass. The manual operations favour the spreading of salmonellas, and due to this the continuous cleaning of the tools and their immersion in containers with water at an adequate temperature (around 82°C) is very important, as well as the frequent change of gloves and a correct advising to the staff. The salmonellas are found mainly in the intestines, in the mesenteric lymph nodes and in the tonsils, so, due to this, a correct evisceration without the piercing or tearing of the intestines is key for avoiding the spreading of the salmonellas.

|

Isolation of Salmonella in MSRV. |

The manual activities in which the work is done on a great surface of the carcass, as for instance the removing of the abdominal lard or fat, or the removing and partial condemnation of parts of the carcass, are also critical for the spreading of salmonellas, because in general terms, the tools and the hands of the workers get contaminated easily and contribute to the crossed contamination of the carcasses. Due to this, in order to reduce the contamination of the carcasses due to salmonella, we must pay special attention on the correct development of the manual operations.

Another possible action in the slaughter line entails the installation of hot water showers or showers with water that contains compounds such as lactic acid, hydrogen peroxide, chlorine derivatives, etc. During the last few months, the experts of the European Food Safety Agency (EFSA) have debated on the authorization for the applying of some of these compounds in showers as a control measure for salmonellas on the carcasses, because up to this moment they were not permitted and can have a considerable efficacy.

What happens in the butchering room ?

As it can be seen in figure 2, during the chilling process, if it is carried out during an enough amount of time and in adequate conditions, there is a significant reduction in the detection of salmonellas on the carcasses. Our experience tells us that the prevalence on the carcasses after chilling of at least twelve hours is 4 times less than before these processes are performed. The butchering, being a point in which the raw matter is meat, is where a lower number of actions can be carried out. Due to this, the best strategy that can be implemented is, without a doubt, to avoid the arrival of salmonellas to the butchering room. In a study carried out in various butchering rooms we found salmonellas, with a low frequency, in the conveyor belts and the workers (hands and tools), but we found them with a relatively high frequency in the organic matter accumulated on the saws and other machines as, for instance, the derinders. Due to the speed of these lines, it is difficult to take measures with regard to them, but the cleaning of the tools and of the working surfaces, as well as the elimination of organic matter remnants during the stops along the working day, and the exhaustive cleaning at the end of the working day are actions that can be taken into consideration in the butchering room, although the ideal situation would be to attain effective measures in the processes previous to the butchering.

We have tackled the control of swine salmonellosis from the perspective of the abattoir. Salmonellas are a causative agent of food poisonings that encompass all the points in the production chain, and the abattoir can have a strategic and fundamental role in its control due to its situation in the food chain and to the possibilities that it offers.

Apart from the reduction of the prevalence in the farms, the improvement of the hygiene during the transportation and in the lairage pens of the abattoir, and the implementation of HACCPs programmes, as well as strategic measures, as for instance showers or logistic slaughters separating the pigs that come from farms contaminated by salmonellas from those that come from salmonella-free farms, can improve noticeably the final levels of salmonella found on the carcasses and, as a consequence, in the meat.