Having a correct lighting is basic for the productivity of the sow and the farm workers. The recommended minimum is 250 lux for 16 hours per day. We must remember that, in farrowing rooms, a good lighting is needed for two reasons: it increases the weight at weaning and it allows the sow to 'start' her pregnancy during the previous lactation.

To achieve a correct lighting it is necessary to have a good artificial lighting system for the season with less natural light hours and to compensate the part of the day, and the whole days, when natural light is not intense enough.

Lighting can be increased considerable with other solutions apart from artificial lighting. Here we have some:

Whitewash the buildings

Whitewashing is very cheap and easy.

Whitewashed pregnancy control building. We can see that with a little natural light entering the building, the lighting is good.

Use white plastic partitions

Apart from their brightness, they are easy to clean and disinfect.

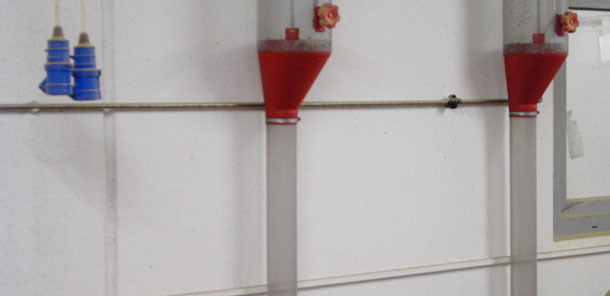

Farrowing room with plastic wall surface

Paint the walls white

It is more expensive than whitewashing, but it lasts longer.

There is a better lighting with painted than with whitewashed walls.

Placing a partially translucent ceiling

It can be done in new and old buildings. Before buying and placing the translucent ceiling pieces we must find out about the different materials that can be used and about their mechanic, light and thermal properties, because there are great differences in the way that they let light in and heat the buildings. Another element to bear in mind is durability, because some materials turn yellow with time. In buildings located in hot regions, if we make translucent too big a part of the ceiling, this can cause too much heat in summer. We can also face the opposite problem in winter in cold regions. It is convenient that the translucent part of the ceiling is located as high as possible to obtain a better diffusion of light. Common materials for this kind of ceilings are polythene, acrylic, polyester, PVC or polycarbonate. There are many kinds and mixes with additives and other resins that make the properties change a lot.

Confirmed pregnancy building with translucent part placed lengthways

Old building in which lighting has been improved with a window.

Farrowing room with translucent part placed across. The lighting is good, but less uniform than when the layout is lengthwise.

Farm with translucent ceiling. We can see the considerable increase in lighting.

Being placed lengthwise and at a great height, we get a more uniform distribution of light than with other layouts.