The Swedish model

Sweden stands out within the EU for having been a pioneer in implementing animal welfare regulations and was one of the first countries to make the use of bedding or manipulable material mandatory and to ban routine tail docking (in 1988 all surgical interventions that could not be justified from a veterinary point of view, including tail docking, were banned). Moreover, in some cases, their regulations are even more stringent than those established at the European level, such as the minimum surface area requirements per animal (pigs are kept in pens of 0.8-0.9 m2/pig starting at approximately 30 kg live weight) and the prohibition of the use of full slat flooring. These regulations have led to a more rigorous system in terms of infrastructure and management, but have also encouraged innovation to improve efficiency.

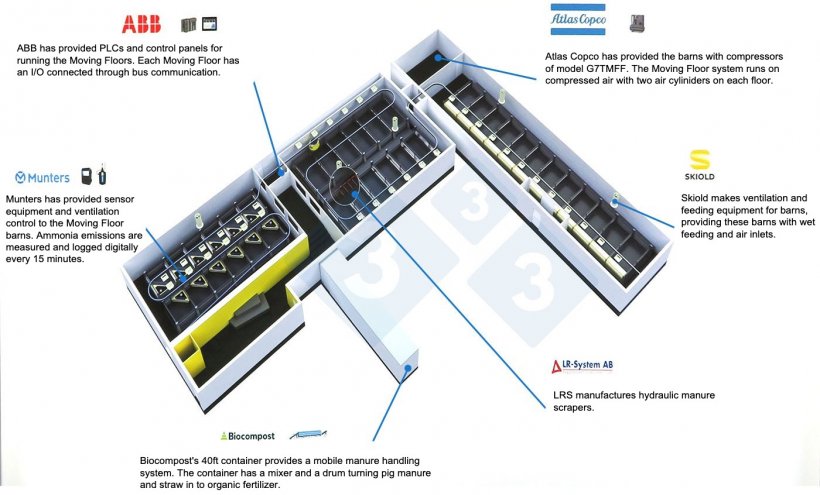

Moving Floor system pilot farm located in Västmanland County, Sweden.

Innovation in manure management: opting for a moving floor system

During our visit to a finishing farm that produces 8,000 pigs per year in Västmanland County, we learned about one of the first implementations of the Moving Floor system in pig production. This technology, widely used on over 100 commercial cattle farms across Europe, Canada, and China aims to improve pen hygiene, reduce emissions, and optimize operating costs.

Layout of the barns with Moving Floor system and collaborating companies. Source: Moving Floor.

Since January 2024, this farm has served as a pilot project. Its remodeled barn has 12 farrowing rooms, 12 nursery pens, and 12 finishing pens with 10 animals per pen (1.16 m2/animal). The renovation has been supported by the Swedish Board of Agriculture and the Swedish Energy Agency, reflecting the country's commitment to sustainability.

How the system works

The Moving Floor is an automated moving floor system consisting of an ultra-strong conveyor belt that slowly moves the slurry (approximately 6 cm per movement) by means of a pneumatic drag mechanism. The slurry is removed to the lower channels, where it is moved outside of the barns, minimizing its accumulation and reducing gas emissions.

Pen with finishing pigs on a movable floor.

The floor of the pens is always kept clean, and by scraping the slurry a few hours after being excreted, the system prevents the maximum release of ammonia, which occurs four to six hours after excretion.

Scraper system at the bottom of the pens that moves the manure out of the barns.

The control of the system by PLC (Programmable Logic Controller) makes it possible to manage the floor movement, straw distribution, and automatic pit cleaning, allowing different cleaning sessions to be programmed. In addition, a safety device at the end of each pen stops the floor movement if a pig gets trapped in the slurry outlet.

Mobile floor system implemented in lactating sows.

Another key feature is the automatic supply of bedding material (chopped straw or shavings) through a mobile dispenser synchronized with the floor cleaning. This system encourages natural rooting behavior, reducing boredom and aggressive behavior.

Preliminary results and scientific validation

The system is being evaluated by institutes such as the Swedish Research Institute (RISE) and the Swedish Veterinary Agency (SVA), analyzing its efficiency in reducing emissions and its impact on animal welfare.

No negative correlation between floor movement and pig behavior has been detected to date. In addition, more than 17,000 photos have been taken to assess limb injuries, concluding that the system is safe.

Ammonia and ventilation sensors optimize cleaning cycles, achieving up to 85% reduction. While traditional systems have ammonia levels between 7 and 14 ppm, the moving floor reduces them to 1-4 ppm.

Gas sensor.

Slurry management and composting

The farm is connected to a centralized biogas plant and is also piloting on-site composting, using a small drum to process the slurry. The idea of the composting drum is to take advantage of the natural self-heating process of the manure and accelerate it. Emissions generated during the process can be treated by a scrubber, unlike open-air windrow composting.

This process aims to obtain high-quality fertilizers with lower ammonia content.

Composting drum for part of the manure from the barn, mixed with horse manure to balance the raw material to be composted.

Economic and operational considerations

According to the data they provided us, the cost of implementation is estimated at approximately €430/place (almost half the cost of building new facilities in Sweden, which is around €1,000/finishing place) since the moving floor system only requires a flat floor surface for implementation, which eliminates retrofitting work in the case of farm remodeling. Maintenance costs average 10 to 15 euros per pen per year for spare parts. Average energy consumption is less than 500 kWh per sow per year. Regarding payback (return on investment), on average, the investment in the system is recovered in three years, considering both the operating costs and animal health benefits and the higher growth rate of the pigs.