Methane is a powerful greenhouse gas, and within the pig meat supply chain, methane accounts for around 25% of greenhouse gas emissions. The lifetime of methane in the atmosphere is short compared to that of CO2, and therefore methane mitigation on farms could make an important contribution to curb global warming in the short term.

On pig farms, manure storage is responsible for 85% of methane emissions, and therefore manure management is the main target for mitigation. Among several strategies for handling or treatment currently investigated, low-dose acidification of liquid manure is a novel approach that could be a flexible and cost-effective technology for climate action.

Methane formation and mechanism of inhibition

Methane is produced by specialized microorganisms (methanogens) that interact with several other groups of microorganisms to degrade the organic matter in manure. The methanogens that are active in slurry are different from those in the digestive system of the animals, and slurry acidification works by delaying the adaptation and growth of the “new” methanogens who can be active in this stressful environment.

Slurry acidification with sulfuric acid will change chemical balances that inhibit methanogens. Additionally, a specialized group of bacteria can utilize sulfate from sulfuric acid, directly competing with methanogens and producing hydrogen sulfide, which further reinforces methanogen inhibition. This may help maintain the inhibition over time.

What is slurry acidification?

Acidification of slurry by concentrated sulfuric acid (96%) was developed around 25 years ago in Denmark as a method to avoid ammonia losses from slurry. Later it was discovered that this treatment also effectively reduced methane emissions, and that in fact several other compounds that contain sulfur also show some inhibition (Petersen, et al. 2012).

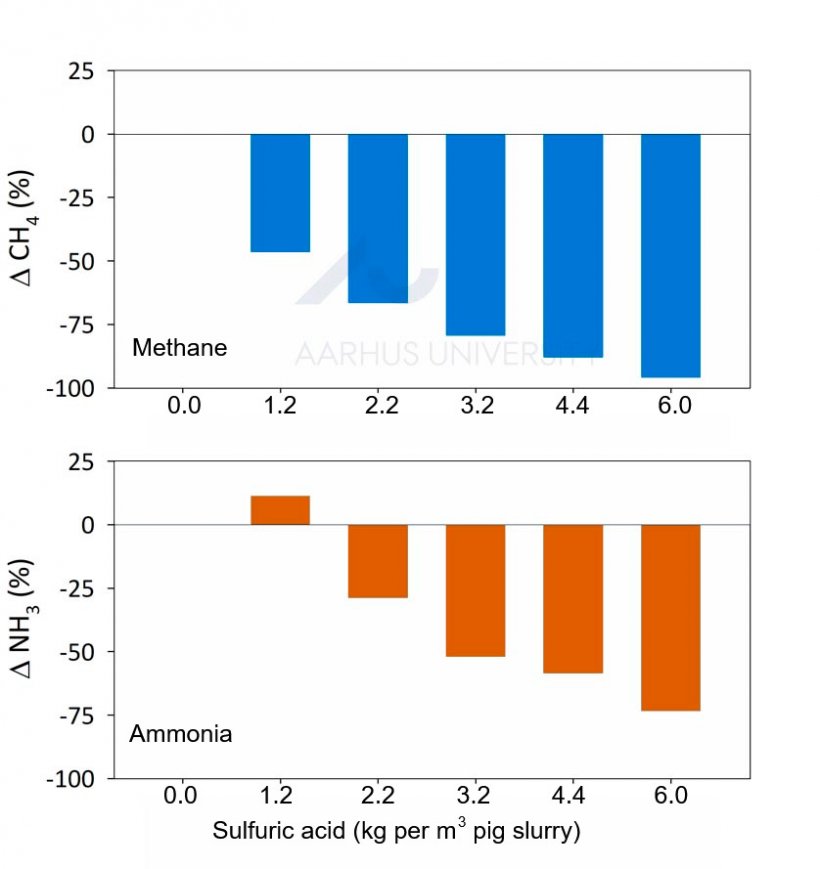

Studies in several countries have later confirmed these observations, and that sulfuric acid is the most powerful agent for inhibiting methane emissions. This led us to consider what would be the effects of lowering the sulfuric acid dose on methane and ammonia emissions. What is the climate benefit with a lower acid dose, and what are the tradeoffs in terms of nitrogen losses and cost savings?

A pilot-scale study was carried out in 2021. It showed that low-dose acidification with 2 kg sulfuric acid per ton of pig slurry (one third of the prescribed dose for ammonia mitigation) could be highly cost-effective for methane mitigation but with less reduction of ammonia emissions (Ma, C., et al., 2022).

Figure 1. Danish regulations prescribe the addition of 6 kg sulfuric acid per m3 pig slurry to reduce ammonia emissions. In a pilot study, six different doses of acid (0 to 6 kg per m3) were used. The two graphs show percentage changes in methane and ammonia emissions, with untreated pig slurry as reference. Source: Ma et al., 2022.

Slurry acidification on practical farms

Concentrated sulfuric acid is hazardous, and technical solutions are needed to ensure the health and safety of both staff and animals. A fully automated commercial technology for slurry acidification in pig barns already exists, but investment costs are high. Slurry can also be acidified in outside storage tanks, where acid is added during vigorous mixing. This must be done by trained personnel using the required safety equipment and procedures, and it is typically carried out by a contractor.

Acidification in outside storage tanks is done today on many farms in Denmark, but shortly before field application. Here, the purpose is to reduce ammonia losses during spreading. However, to reduce methane emissions during storage it is necessary to acidify the slurry in storage tanks during the storage period.

Methane emissions are particularly high during summer and early autumn, and therefore acidification should take place in June, and again around 1 September. Fresh slurry from barns will be pumped to the storage tank at regular intervals. Enough acid should be added in June and September to allow for this dilution and still have a final concentration of 2 kg sulfuric acid per m3 slurry at the end of the storage period.

Frequent slurry transfer from the barn to a storage tank can enhance the overall reduction of methane emissions from slurry by allowing acidification or other treatment technologies outside the barn. However, many existing pig barns have deep pits or shallow pits with a pull-plug system, which cannot be emptied frequently. There is a need to develop and adopt new housing designs for improved manure management.

Low-dose acidification to reduce methane emissions from storage facilities should take place in late spring. It is currently achieved by adding sulfuric acid (96%) during intense mixing. Photo: Søs Lindeborg Pedersen, SEGES Innovation.

Verifying the efficacy of low-dose acidification

Based on the promising results at laboratory- and pilot-scale, the low-dose acidification technology is now being evaluated at practical scale in a study that involves 16 slurry tanks, eight tanks on pig farms and another eight on cattle farms. Six of the eight tanks are acidified. Slurry samples have been collected several times during storage in different positions and at several depths for analysis of slurry composition and methane production rates.

There is a need to have some slurry in the tank already when sulfuric acid is added, and therefore pig slurry was acidified around 1 July and again in September. Most tanks received fresh slurry from the barn at regular intervals.

The results from the first year of the study confirmed that methane production can be effectively inhibited. However, in tanks with pig slurry, which are all bottom fed, we have often seen pockets of slurry near the inlet with high methane production rates even when the slurry was initially acidified. Therefore, further work is needed to optimize the treatment technology and document overall methane mitigation. On-farm measurement campaigns will take place in the next phase of the project.

In a new development, a system for addition of acid during the pumping of slurry from barn to outside storage has been developed by a Danish company and will be evaluated in 2025 on a pig farm and a cattle farm. This would minimize the need for on-farm handling of the acid while ensuring immediate inhibition of methanogens.

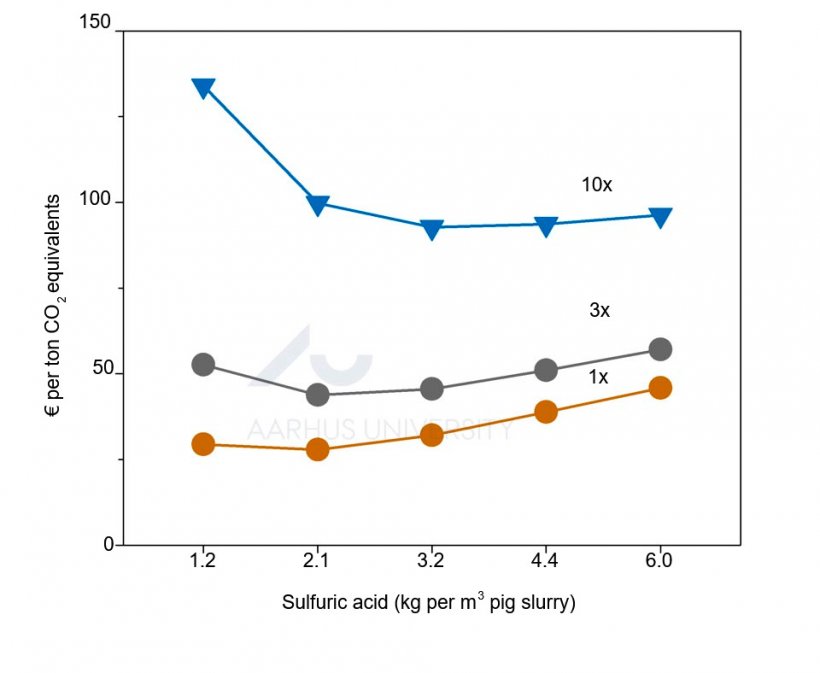

The cost-effectiveness of low-dose acidification strategies will be determined in spring 2026. A preliminary evaluation of cost-effectiveness was done based on the results from the pilot study. The cost of GHG mitigation, expressed as euros per ton of CO2 equivalents, were calculated as a function of acid dose and application strategy (1, 3, or 10 acid treatments) (Fig. 2). Costs considered were acidification by a contractor, the value of N savings from avoided ammonia losses, methane mitigation, and the prevention of nitrous oxide emissions derived from ammonia.

Figure 2. Results from the pilot-scale study were used to assess the economy of slurry acidification for greenhouse gas mitigation. Cost of GHG mitigation by acidification 1, 3, or 10 times annually during storage of pig slurry. Source: Ma et al., 2022.

The cost of EU Carbon Permits is currently at 75€ per ton CO2 equivalents. Depending on the need for mixing during storage, low-dose acidification could be a cost-effective solution.

Acidifying pig slurry in storage tanks one to three times per year could be a cost-effective strategy for mitigating greenhouse gas emissions in agriculture. Cost efficiency can be further enhanced by frequently transferring slurry from barns to outdoor storage tanks, allowing acidification to impact a larger share of the total methane emissions from manure management. Additionally, since the majority of CH₄ emissions occur during summer and early autumn, applying the full acid dose—e.g., 2.1 kg of sulfuric acid/ m3 pig slurry in the final volume—before summer could maximize mitigation during the peak emission period while preventing excessive sulfur input into soils when the slurry is applied in the field.