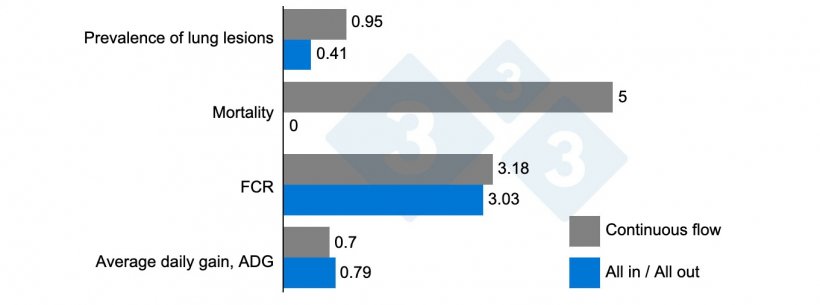

Proper management should start with good room hygiene where pigs are to be raised and that implies complete emptying followed by proper cleaning and disinfection. Proper all-in/all-out (AIAO) management will have a direct impact on productivity and will reduce the feed conversion ratio (FCR).

Photo 1. Clean weaning room.

Graph 1. Effect of all-in/all-out management on various production indexes. Scheidt AB, et al. 1995.

The stocking density at which pigs are housed will also have an impact on the efficiency of diet utilization. Results from numerous research trials make it clear that as post-weaning and finishing pigs have less space per individual, feed intake decreases, with a decrease in daily gain. It is not clear whether a reduction in feed intake causes the decrease in daily gain, or whether a decrease in daily gain results in a reduction in daily feed intake. The impact on feed conversion efficiency is less predictable and may well depend on the increase in stocking density, but we cannot forget that providing too little space per pig increases the chances of triggering behavioral problems such as tail biting that will, among other things, have a negative impact on feed conversion.

Photo 2. Example of a finishing barn with excessive density.

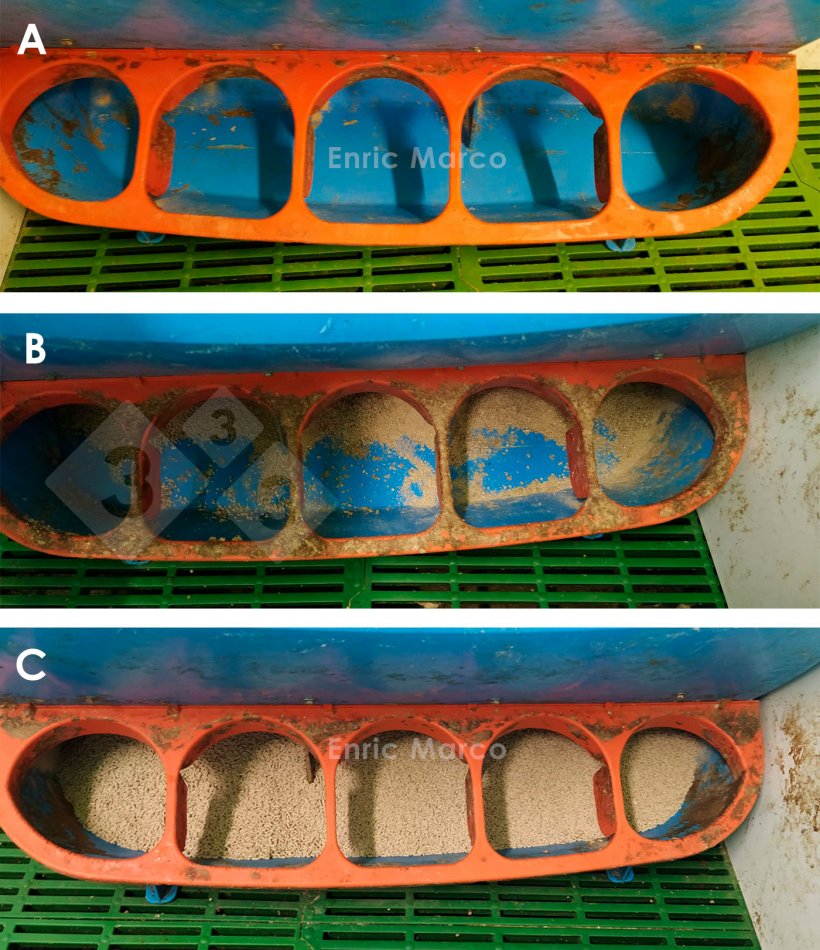

Restricted feed intake and increased competition for feed, due to limited access, are generally confounded in group housing conditions. Reducing the feeder space provided to pigs has been shown to have a similar effect to reducing the surface area provided to pigs. Generally, increasing the number of pigs per feeder will reduce feed intake and reduce daily gain, but the feed conversion ratio would only be affected when the reduction in intake is such that maintenance requirements begin to represent a significant percentage of total requirements (due to reduced growth requirements). Restrictions can be determined by an insufficient number of feeders for the pigs in the pen or because the distribution of feed output in the pen is not homogeneous, thus reducing the available space. The correct regulation of the feeders will also be important, because if they are too closed they will make it difficult for the pigs to access the feed, causing the same effect as a reduction of the feeder space. However, excessive opening will lead to feed wastage that will negatively impact feed conversion.

Photo 3. Nursery pig feeder according to its opening: A- Too closed. B- Correct regulation. C- Too open.

Under field conditions, it is common for the hopper capacity to be small or to not be filled completely (excessively short delivery tubes) leading to situations where there is always a feeder that runs out of feed. It has been shown that intermittent periods of fasting during finishing phases would generate an effect similar to reduced feeder space, since the time of use of the trough in question would be limited, the pigs not being able to ingest the maximum daily amount of feed.

Photo 4. An out-of-feed event in a nursery.

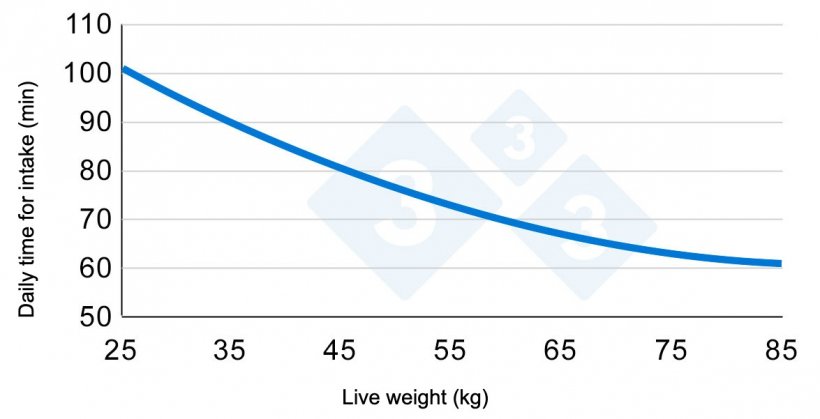

Lack of sufficient water, especially in hot weather, can lead to reduced daily feed intakes which, in turn, will have a negative impact on production results and may negatively influence feed conversion ratios in the case of severe restrictions.

Graph 2. Variation in time spent on feed intake during growth of pigs. Adapted from Hyun et al., 1997.

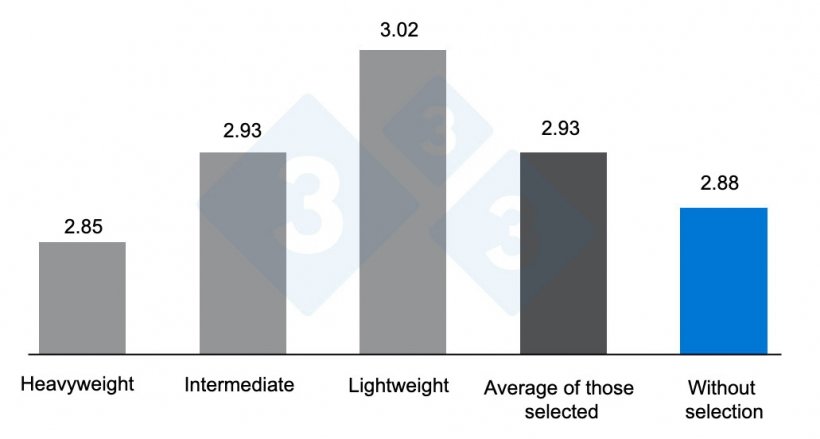

Management in filling and emptying the barns will also have an impact on feed utilization efficiency. Not sorting by size upon entry in the finishing phase, contrary to popular belief, improves the FCR of the group rather than worsening it (see graph). When emptying the barns, selling the heaviest pigs early will free up space and optimize production outcomes for the remaining pigs. The practice of fasting before loading for slaughter, if done correctly, will also result in feed savings and, therefore, in improved feed conversion. However, excessively long fasts (>24 h) bring about weight loss that will prevent the benefits of fasting from being realized.

Graph 3. Effect of selecting or not selecting pens by weight on feed conversion ratio. Adapted from O'Quinn et al. 2001.

The relationship between the farmer and pigs also has an impact on the production results obtained. Aggressive attitudes that cause fear in pigs have been related to poorer production results, including poorer conversion ratios.

Deficiencies in the feed storage or distribution system on the farm, errors in the distribution of the different types of feed, broken feeders, etc. can cause feed wastage which, naturally, will result in poorer feed conversion ratios.

Continue to delve deeper into the external factors affecting the FCR by reading articles on:

Or browse the tool to identify the cause of your elevated FCR:

Return to the beginning of the tool