After reviewing the previous articles on how to store vaccines correctly, it is now time to administer them.

Each farm should have its own vaccination plan adapted to each case by the veterinarian responsible. It should describe the types of vaccines to be used, their route of administration, and the exact age or point in the cycle in which they should be administered. It is essential to administer the vaccine at the indicated time to be successful.

Vaccine administration routes

Whenever a vaccine is to be used, in addition to following our veterinarian's guidelines, we must read the package insert to make sure we follow the manufacturer's recommendations:

- Temperature of administration

- Volume

- Dosage

- Withdrawal period, if any

- Adjuvant inclusion

- Mixing of vaccines if possible

- Etc.

Vaccines can be differentiated according to the route of administration. The most frequent are:

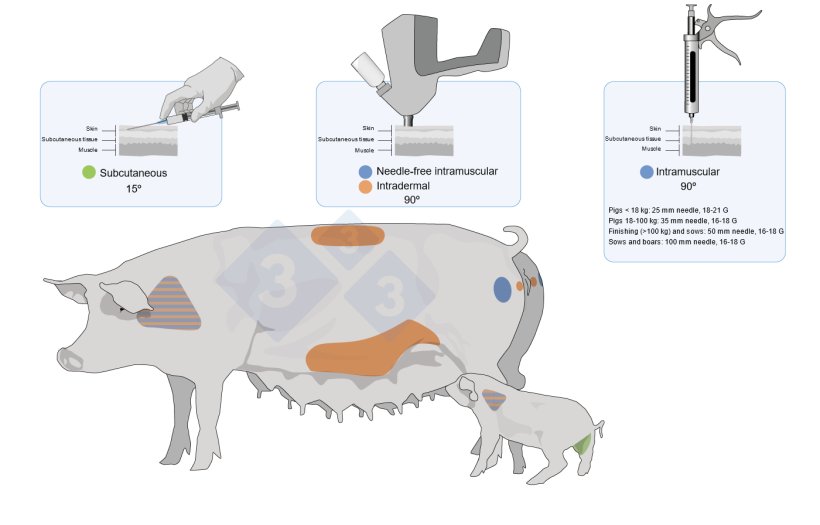

1. Intramuscular: we can differentiate between:

- Vaccination with a needle: it is essential to choose the correct needle size (Figure 1) to:

- Be able to pass through the skin, the fat layer, and enter the muscle depending on the size of the animal.

- To allow the liquid to flow without problems depending on the density of the vaccine and the volume to be administered.

Figure 1. Needle sizes.

- The most frequent injection site is in the neck, but they can also be administered on the ham of the hind legs. Both sites have advantages and disadvantages, the most significant are:

- Neck:

- Advantages:

- Good vascularization facilitates the absorption and distribution of the vaccine in the animal.

- Wide area to administer.

- Disadvantages:

- Hard to access when the animals must be accessed from behind, which can pose a risk to the operator.

- Possibility of abscesses when administered incorrectly or the needles are in poor condition.

- Advantages:

- Ham:

- Advantages:

- Easy to access when animals are in crates or pens.

- Disadvantages:

- Can cause abscesses in the ham and therefore its condemnation.

- Advantages:

- Neck:

- Intramuscular needle-free administration via high pressure devices in the neck area.

Needle-free systems reduce the risk of pathogen transmission, wounds or abscesses, and potential broken needles in the carcass. For the staff, they also eliminate the risk of accidental injection. In these systems, the application pressure must be calibrated according to the type of animal.

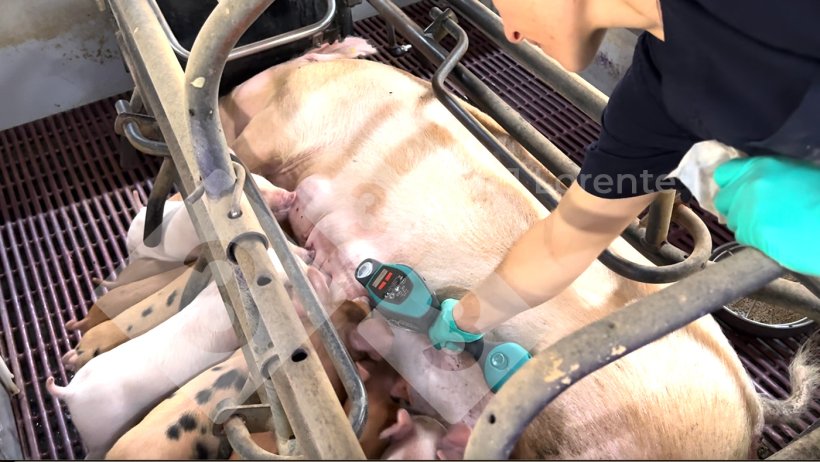

2. Intradermal: They can be administered with a needle, but needle-free administration with special high pressure devices that introduce a small volume in the dermis is increasingly used. The injection sites should have little hair and be sufficiently flat. The most frequent are the neck, ham, back, and for sows also on their middle above the udders. Figure 2. Intradermal vaccination device.

3. Subcutaneous: It is injected under the skin and is usually used for smaller piglets. The ideal injection site for these is the inner thigh in the skin folds.

4. Oral: Administered mainly through the drinking water. This system facilitates administration in large groups but only certain vaccines can be administered via this route. It is important not to use other products that may alter the effectiveness of oral vaccines: chlorine, other medications, etc.

5. Intranasal: The vaccine is absorbed through the mucous membranes and stimulates an immune response in the animal.

In all cases, the administration site should always be clean and dry.

Figure 3. Vaccine application sites and types in pigs and piglets.

Administration route according to the type of animal

1. Piglets in the farrowing room: Pick them up one at a time to ensure proper administration.

2. Nursery piglets and finishing pigs

- Piglets up to 25 kg: We must pick them up one at a time to ensure the vaccine is administered at the proper site. To facilitate this process, we can divide the pen in two, leaving less space to catch the piglets. As they are vaccinated they can be marked and left on the other side. In many cases, the aisle can also be useful for this.

Figure 4. Nursery barn with large groups with the option for paneling and reducing spaces.

Figure 5. Finishing barn with large groups with the option for paneling and reducing spaces.

- Pigs over 25 kg: They can be vaccinated without picking them up individually. Reducing the available surface area when vaccinating helps do so more precisely but this is not strictly necessary. If we work with large groups we should have systems that allow us to do this routinely.

To facilitate this type of vaccination, syringe “extension” systems can be used. These systems can be useful because they improve position when vaccinating, but you have to be used to this and trained in their use since:- It is easier to miss the proper injection site, being the neck in this case.

- It is easier for the needles to bend.

Figure 6. Vaccination extender.

- Boars and sows in crates

- They are vaccinated one at a time, preferably from behind if the system allows.

- Sows or boars in groups:

- Small groups: If we have a system that feeds all animals simultaneously, the best time to vaccinate will be during feeding.

Figure 7. Finishing pigs eating at the same time.

- Large groups:

- If the system can select the animals and separate them from the group, we will do so in smaller groups to be able to vaccinate them.

- If the system does not select the animals, we have to look for when the animals are resting and calm and do it slowly, approaching from one side so as to not scare them.

- Small groups: If we have a system that feeds all animals simultaneously, the best time to vaccinate will be during feeding.

For any age and depending on the health status of the farm, it will be necessary to change needles between litters or between adult animals, following the recommendations of the veterinarian in charge.

Managing vaccination materials

1. Needles

Using the appropriate size of needle is essential (Figure 1).

The farm must have a written protocol for changing needles (Table 1), which must be adapted to the specific health situation since needles can transmit diseases. The veterinarian will make the corresponding decisions.

In any case, we will change the needle whenever it has bent or lost its sharpness since needles in poor condition may have a greater risk of breaking or may cause injuries.

Table 1. Basic protocol for changing needles on the farm. It must be adapted according to the health status of the farm.

| Animals | Situation | Needle change |

|---|---|---|

| Nursing piglets | Every litter | |

| Nursery piglets | Small groups (up to 30 piglets) | Every group |

| Large groups | Every 30 piglets | |

| Finishing pigs | Small groups (up to 12-15 pigs) | Every group |

| Large groups | Every 10 animals | |

| Sows | Farms with good health status | Every 5 animals |

| Farms with poor health status | Every animal | |

| Boars | Every animal |

The hospital pen and quarantine areas must have all the necessary supplies for vaccination and treatment that are to be used in that area EXCLUSIVELY. This includes snares, needles, syringes, markers, etc.

If the needle breaks when vaccinating and we suspect it remains inside the pig, we must ear tag the affected animal and separate it to notify the slaughterhouse. There are needles that are detectable in the slaughterhouse through the use of metal detectors. There are meat companies that require their suppliers to use these to reduce the risk of needles in the carcass.

Used needles and vaccine remains must be collected in specific containers and each farm must have a waste management contract. Figure 8. Sharps containers. Photo courtesy of National Pork Board, Des Moines, Iowa.

2. Vaccination syringes and inyectors

We must use the syringes and inyectors the veterinary services recommend and ensure they function correctly.

After EACH USE, the syringes and injectors must be washed to remove all traces.

Figure 9. Clean vaccination supplies.

We must have a maintenance plan for all the supplies used to vaccinate.

In the last article of the series, we will talk about how to minimize possible vaccine failures.