Vaccine use on our farms is an essential practice for disease prevention, with increasing prominence as a tool to drastically reduce the use of antibiotics. However, vaccines are sensitive biological products and to ensure that they work properly we must carefully control some critical points in their handling:

- How should vaccines reach the farm?

- How should we receive and store vaccines?

- How should we administer vaccines depending on the type?

In this first article, we will address the transport of vaccines and reception at the farm.

1. Transport and on farm reception

It is important not to fail in the first stage of the process, so we should ensure that the vaccines are transported by specialized means and by personnel trained to handle biological material.

The critical points before reaching the farm are:

- Packaging: Ensure the cold chain is maintained and the stability of the vaccine. Some recommendations may be:

Figure 1. Double insulated box.

- The inside of the transport box should be made of expanded polystyrene or polyurethane and should be solid, insulating, and airtight. For this purpose, using a double box with a cardboard exterior and an interior made of the aforementioned material can help.

- Use cold accumulators to maintain the right temperature. We must prevent the bags from being in direct contact with the vaccines to prevent freezing.

- Use any material that allows us not to leave empty spaces inside the box to prevent the vaccines from moving.

- Always include an electronic device inside the boxes to record the temperature during the transport or at least maximum and minimum thermometers to verify that the desired temperature range is maintained:

Figure 2. Data logger.

- The temperature should always be between 4 and 8 ºC. Thermal variations of more than 6ºC can damage the vaccines.

- Transport:

- We should ensure full traceability of the process and a complete record of the process.

- We need a transportation system that guarantees the cold chain is maintained.

Once the package has arrived at the farm and before accepting it, we must:

- Check package integrity:

- Check the exterior: If more than 5% of the exterior is damaged, it should be recorded.

- Open the cardboard box and check that the inner insulating box is not damaged and that it is tightly closed.

- The last step would be to check that the vaccine boxes are in good condition:

- No traces of moisture → This could tell us that the cold chain may have been broken.

- No vials are broken → Just 1 broken bottle is a sign of improper shipping and the delivery should not be accepted.

- Check traceability:

- Review the transportation sheet to check departure times.

- Review the packing slip and check against the actual shipment to ensure that the number, batches, and expiration dates are correct.

- Check the temperature during transport:

- As soon as we open the box, we must check the maximum and minimum thermometer or the datalogger if it has one. The temperature should always be within the range of 4 to 8 ºC. If this is not the case, the shipment must be rejected and the supplier must be notified immediately.

- There are also disposable temperature indicators that allow us to check if the package has ever gone below 0ºC. We could place it between the boxes of vaccines for testing.

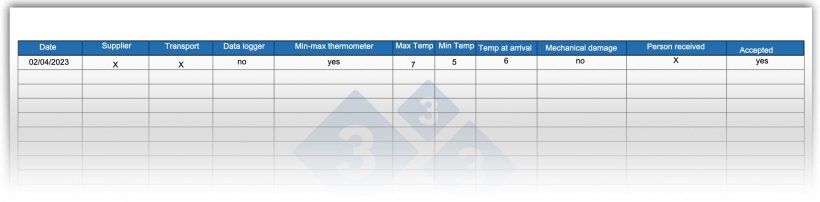

Figure 3. Example of a receiving sheet.

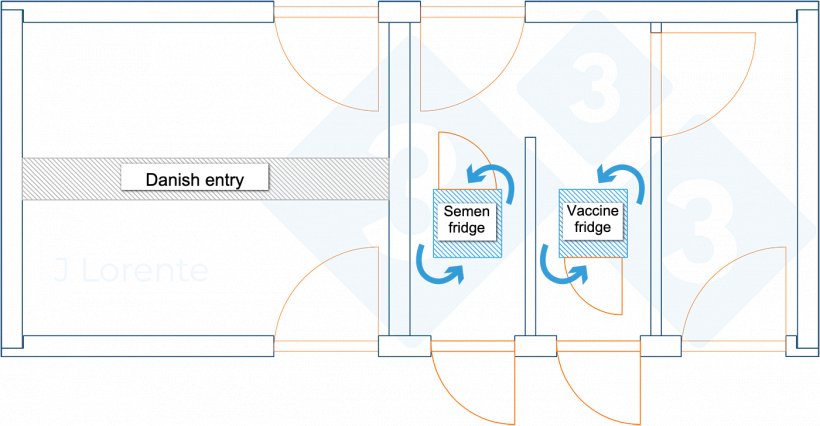

Figure 4. Reception area with separation of areas. Doors: Farm entrance, semen reception, reception of products requiring refrigeration, and general reception of medications.

Figure 5. Reception area layout with separation of areas.

- Avoid exposing the vaccine directly to the sun → The vast majority of vaccines are photosensitive so a short exposure to direct sunlight may alter their effect.

- Keep the area clean and dry → Moisture can reduce the shelf life of vaccines and clean areas will reduce the possibility of cross-contamination.

- Comply with all biosecurity measures to prevent the entry of any pathogens into the farm through the vaccine package. To do this we can:

- Discard the outer box of the vaccines: This should remain in the dirty zone.

- Have a rotating refrigerator that allows vaccines to be dropped off from the outside and picked up inside without any contact.

- Correctly disinfect the containers to be brought into the farm.

- Always keep vaccines within their proper temperature range between 4 and 8ºC.