Introduction

Precision livestock farming is an innovative production system approach based on the intensive and integrated use of advances in animal sciences and in the new technologies of information and communication (Berckmans 2004). Its main objective is to optimize animal production and the management of the productive processes (Bos et al. 2003). Precision feeding as part of the precision livestock farming approach offers today many opportunities such as the increased nutrient efficiency that can be obtained by reducing excess nutrients controlling the variability that exists among farm animals (Pomar et al. 2014; Wathes et al. 2008).

Precision feeding

Feed cost is by far the greatest input cost in pork production (65-75%) and improving nutrient efficiency has great impact on profitability. In growing-finishing pig operations, feeding programs are proposed to optimize population responses at minimal feed costs. However, nutrient requirements vary greatly between the pigs of a given population (Brossard et al. 2009; Hauschild et al. 2010; Pomar et al. 2003) and for each pig these requirements change over time following individual patterns. In order to optimize population responses nutrients are provided at levels that satisfy the requirements of the most demanding pigs of the herd, with the result that most of the pigs receive more nutrients than they need to express their growth potential (Hauschild et al. 2010). This is because, for most nutrients, underfed pigs will exhibit reduced growth performance and overfed ones will exhibit near optimal performance.

Precision feeding is based on the fact that animals within a herd differ from each other in terms of age, weight and production potential and therefore, each has different nutrient requirements. Precision feeding involves the use of feeding techniques that allow the right amount of feed with the right composition to be provided at the right time to each pig in the herd (Pomar et al. 2009). Essential elements for precision feeding in livestock production systems include,

- Evaluating the nutritional potential of feed ingredients;

- Estimating the real-time nutrient requirements of individual pigs;

- Formulating balanced complementary feeds at minimal cost and limiting excess nutrients;

- Providing individual pigs with daily tailored diets.

Managing feeds and animals by advanced computerized technologies

The proposed sustainable precision livestock farming system automatically collect in real-time individual feed intake and body weight information. This information is used to estimate optimal nutrient concentration of diets to be given daily to each pig of the herd using new modelling approaches (Hauschild et al. 2010). To this end, automatic and intelligent precision feeders (AIPF) developed at the University of Lleida, Spain in collaboration with Agriculture and Agri-Food Canada (Pomar et al. 2011) identifies each pig that introduces his head into the feeder and then blends two or more feeds delivered, upon animal requests, in small meals providing the estimated optimal nutrient concentration.

Intelligent Precission Feeders (AIPF). Source UdL

The impact of moving from conventional to precision feeding systems in growing-finishing pig operations on animal performance, nutrient utilization, and body and carcass composition was studied in a recent experiment (Andretta et al. 2014). Fifteen animals per treatment for a total of 60 pigs of 41.2 (SE = 0.5) kg of BW were used in a performance trial (84 d) with 4 treatments: a 3-phase feeding program (3P) obtained by blending fixed proportions of feeds A (high nutrient density) and B (low nutrient density); a 3-phase commercial feeding program (COM); and 2 daily-phase feeding programs in which the blended proportions of feeds A and B were adjusted daily to meet the estimated nutritional requirements of the group (MPG) or of each pig individually (MPI). Daily feed intake was recorded each day and pigs were weighed weekly during the trial. Body composition was assessed at the beginning of the trial and every 28 d by dual-energy X-ray densitometry. Nitrogen and phosphorus excretion was estimated as the difference between retention and intake. Organ, carcass, and primal cut measurements were taken after slaughter.

Table 1. Performance of pigs fed according to a 3-phase feeding program (3P) obtained by blending fixed proportions of diets A and B, a commercial 3-phase feeding program (COM), or two daily-phase feeding programs in which the blending proportions of diets A and B were estimated daily to match the lysine requirements of the group (MPG) or of each individual pig (MPI) (trial AIPF I)1

| Treatments | SEM | P-value2 | ||||

| 3P | COM | MPG | MPI | |||

| ADFI3, kg/d | 3.05a | 2.73b | 3.07a | 3.05a | 0.043 | 0.0025 |

| ADG, kg/d | 1.11 | 1.07 | 1.11 | 1.10 | 0.011 | 0.5805 |

| FCR, kg/kg | 2.76a | 2.58b | 2.81a | 2.78a | 0.035 | 0.0095 |

| APD, g/d | 161 | 155 | 155 | 154 | 0.210 | 0.6492 |

| Final BW, kg | 134 | 131 | 135 | 136 | 1.170 | 0.2422 |

1 LSmeans obtained from a repeated measures analysis, ADFI: average daily feed intake, ADG: average daily gain, FCR: feed conversion ratio, APD: average daily protein deposition, BW: body weight.

2 Effects of treatment, period and interaction were considered in the analysis. Period was significant (P < 0.01) for all variables. Interaction period*treatment was significant for ADFI (P < 0.01), ADG (P < 0.01) and FCR (P < 0.05).

3 Means within lines followed by different letters are significantly different (P < 0.05).

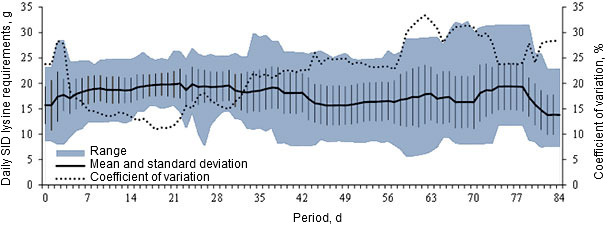

The between-animal variation in SID Lys requirements was high (Figure 1) with intra-day SD of 2.9, 3.8 and 4.8 g during the first, second and third feeding phases.The COM feeding program reduced (P< 0.05) ADFI and improved G:F rate in relation to other treatments. The MPG and MPI programs showed values for ADFI, ADG, G:F, final BW, and nitrogen and phosphorus retention that were similar to those obtained for the 3P feeding program. However, compared with the 3P treatment, the MPI feeding program reduced the standardized ileal digestible lysine intake by 27%, the estimated nitrogen excretion by 22%, and the estimated phosphorus excretion by 27% (P< 0.05). Organs, carcass, and primal cut weights did not differ among treatments. In relation to the 3P conventional system, feeding pigs with daily individual tailored diets allowed reducing (P< 0.05) total feed cost by $7/pig (-8%).

Figure 1. Standardized ileal digestible (SID) lysine requirements estimated for each pig in the trial and measures of dispersion.

Conclusion

Feeding growing-finishing pigs with daily tailored diets using precision feeding techniques is an effective approach to reduce nutrient excretion, without compromising pig performance or carcass composition. Furthermore, feeding pigs individually with daily tailored diets formulated based on its own real-time patterns of feed intake and growth represents a fundamental paradigm shift in pig feeding. Besides the fact that animals are fed individually, the application of precision feeding techniques in growing-finishing operations implies that optimal dietary nutrient concentration is no longer a static population characteristic, but a dynamic process that evolves independently for each animal modulated by its own intrinsic (e.g., genetics, health, nutritional status, etc.) and extrinsic (e.g., environmental and social stressors, management, etc.) driving forces.