Introduction

A pig building might be ventilated in several ways, which might be categorized according to the method that is used for moving the air through the building. A first categorization includes natural ventilation and mechanical ventilation.

Each system has advantages and disadvantages, but it is worth noting that pig production performance is similar in trials comparing ventilation principles, when all other things are kept equal. Thus, if the ventilation system and building is dimensioned correctly performance is independent of type of system.

|

|

|

Natural ventilation

|

Negative Pressure

|

|

|

|

Neutral Pressure System

|

Positive Pressure System

|

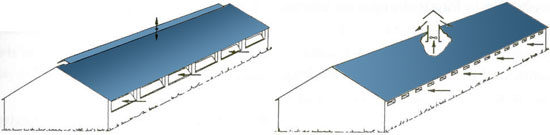

Figure 1. Ventilation principles.

Natural ventilation

A natural ventilation system is working by means of thermal forces and wind speed only. Warm air inside the building is not as heavy as the cooler outside air entering the building. The warm air moves toward the ceiling creating a negative pressure which moves cold air from the outside into the building. Air might also be moved across the building via openings in the sides and by means of the static pressure created by the wind. The amount of ventilation air cannot be controlled since it depends on the inside and outdoor temperature as well as the wind speed. When outdoor temperature is the same or higher than the indoor one ventilation rate might be very low. A natural ventilation system comprises an open ridge at the top of the roof and large opening at the sides. Natural ventilation is not very common in modern pig buildings due to the lack of control of air flow rate and air distribution.

Mechanical ventilation

Mechanical ventilation principles might be further divided into positive pressure systems, neutral and negative pressure system. The categorization is based on the technical way air is moved through a building.

Positive pressure system

A positive pressure system pushes the air into the building via mechanical fans and the air leaves the building through openings in ducts or exhaust pipes. This system is not very common since warm moist air might be pushed into the construction, which leads to condensation and deterioration of the structure.

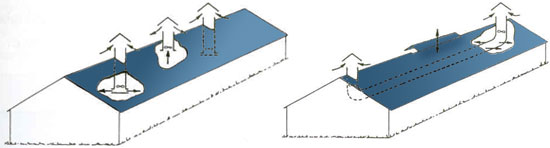

Figure 2. Positive pressure system – fans are pushing air into the building

Neutral pressure system

A neutral pressure system comprises fans that push the air into the building and exhaust fans that move air out of the building. However, to avoid condensation problems a system should be designed with a slight negative pressure.

A neutral pressure system does not incorporate the building as part of the structure and it is not as affected by the wind pressure as other ventilation principles. A common system comprises vertical inlet ducts, which distribute air through air inlets along the circumference of the duct. Inlet holes vary in diameter according to direction of the air. Thus, the largest openings are moving the air toward the corners while the smallest are directing the air toward the walls that are in a shorter distance from the inlets than the corners of the buildings. In this way risk of draught is minimized.

Figure 3. Neutral pressure system with inlet duct (top right) and exhaust fan (top left).

Frequently, an air mixing fan is added to the lower part of the inlet fan, which moves and mixes the warm inside air with cold incoming air during the cold season. In this way risk of cold air currents in the animal zone is reduced.

Figure 4. Neutral pressure system with air mixing fan at the bottom of the inlet duct.

The inlet fans must be placed along the center of the room and evenly distributed. Normally, a room is divided into squares with an inlet duct in the centre of each. The position of the exhaust fans is not so important, since they do not affect air flow pattern. To understand this fact one might compare an exhaust fan with the tube of a vacuum cleaner. Only when the tube is very close to your hand you will be able to feel it suck in air. The greatest disadvantage with a neutral pressure system is the fact that energy use is double of other mechanical systems.

Negative pressure system

Negative pressure systems are the most popular ventilation principle today, which is probably due to the fact that it is simpler to control and consumes less energy than other mechanical systems. The traditional model comprises small inlets along the side walls of the building and exhaust fans in the centre of the room.

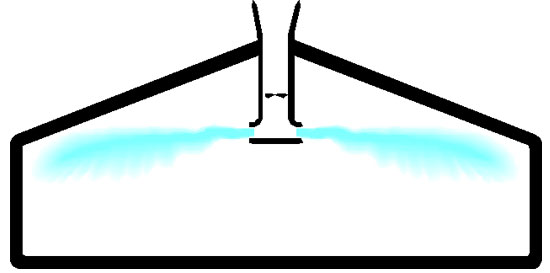

Figure 5. Negative pressure system with air inlet in the wall and exhaust fan in the centre.

Air inlets direct the air toward the centre of the room mixing the incoming cold air with the warm inside air before it reaches the animals. It is important that the inlet flaps are directing the air toward the ceiling during the cold season and toward the pen area during the warm season. To prevent draughts supplement heat should be placed below the inlets.

Inlets might also be placed along the ceiling. In that case air is taken into the building via the roof. Ceiling inlets are suitable for wide buildings. However, since distance from the inlet to the animal zone is small room height should be higher (3 m) than with other ventilation systems to reduce risk of draughts.

Floor ventilation might be combined with a negative pressure system. In that case 30-50% of the ventilation air is removed via channels below the pen floor. Floor ventilation provides a good air quality since most ammonia is removed before it reaches the room. It is a system that is becoming increasing popular in Denmark because it is providing a good working environment and might easily be combined with an air cleaning system that reduces ammonia and odour emission.