Introduction

Since the outbreak of porcine epidemic diarrhea (PED) in North America, researchers have proven that PED virus can be present and infectious in feed, and that other coronaviruses can survive in various feed ingredients (Trudeau et al 2017). They have also shown that PED is transmitted from the U.S. to Canada by importing raw porcine-derived materials (Dee et al 2018). Recently, multiple viruses have been shown to survive in pig feed raw materials. Because of these findings in North America, plans have been developed to decrease the likelihood of swine disease transmission. This article describes the results of recent review of the supply chain of imported vitamins.

Viruses as feed contaminants

In terms of risk in transmitting swine diseases, the type of virus genome has implications on its survival in the environment and how effective a treatment is at inactivating it. The use of heat to inactivate bacteria and other pathogens in feed is commonly used. The best way to characterize viruses is by using inactivation kinetics (Table 1).

Table 1. Characteristics of viruses of interest in North America as feed contaminants

| Virus | Family | Genome | Enveloped | Risk score1 | Survival2 | Heat resistance3 |

|---|---|---|---|---|---|---|

| Foot-and-mouth |

Picornaviridae |

ssRNA, + | No | 9.0 | 12/14 | D50 = 732-1,275 s D80 = 2 - 6 s |

| African swine fever | Asfarviridae | dsDNA, + | Yes | 8.3 | 10/14 | D48 = 638 s |

| Classical swine fever | Flaviviridae | ssRNA, + | Yes | 7.7 | 0/14 | N/A |

| PED | Alphacoronaviridae | ssRNA, + | Yes | 5.7 | 5/7 | D120 = 1,020 s |

1 Order of the most important viral diseases in North America: 1 = least important and 9 = most important (https://www.swinehealth.org/swine-disease-matrix/).

2 Proven survival in 14 ingredients (Dee et al., 2018).

3 Data from (Knight et al., 2013) and (Trudeau et al., 2017c; Trudeau et al., 2017a). The value "D" is the time needed to decrease the concentration of the pathogen in a logarithmic unit (90%) at the temperature indicated in the subscript

Work done so far has shown that viruses are able to survive in feed ingredients and the finished feed long enough to infect animals between countries. However, we must remember that there is a major difference between a hazard and a risk. The hazard is the pathogen capable of harming animals while the risk is the probability that the event will occur. Figure 1 shows a shark as a hazard, but the observer is not at risk while he is on the beach. He will be at risk however, if he enters the water with the shark. Similar to this example, viruses have been shown to survive in feed, but it has not been demonstrated that viruses are present in the feed ingredient supply chain.

Figure 1. The difference between hazard and risk. Source: EFSA

Evaluation of the vitamin supply chain

The U.S. Department of Agriculture's Center for Epidemiology and Disease Transmission has assembled a panel of risk analysis experts to assess the possibility of virus entry into the U.S. via various routes. The expert panel has categorized the risk of African swine fever (ASF) introduction as a negligible (will almost never occur) to moderate risk (equal chance of occurrence and non-occurrence). However, these experts classify the risk with great uncertainty due to the limited amount of information available. Because of these uncertainties, US veterinarians and pig producers have called for the implementation of environmental sanitation and biosecurity programs in both feed mills and the product import supply chain.

Table 2. Summary of introduction routes of African swine fever into the United States (USDA-APHIS Veterinary Services)

| Route | Live hogs | Feed (animal origin) | Feed (plant origin) |

|---|---|---|---|

| Legal | Negligible with low uncertainty | Low to moderate with high uncertainty | Negligible to moderate with great uncertainty |

| Illegal | Negligible to low with moderate uncertainty | Negligible to low with high uncertainty | Low with high uncertainty |

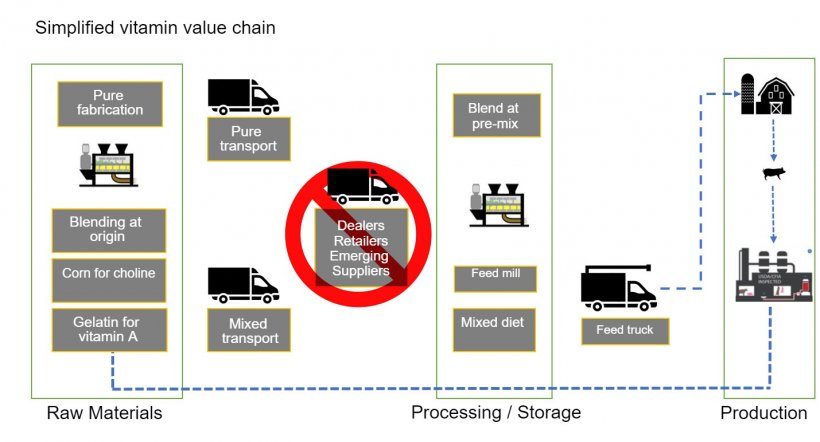

Figure 1. General description of the vitamin value chain for animal feed.

The vast majority of vitamins are produced in China and, depending on the vitamin, it is almost impossible to acquire the volume needed to feed pigs in the USA without using vitamins from China. Therefore, scientists from the University of Minnesota have met with pig producers, manufacturers, and suppliers of vitamins for animal feed. Vitamins are made in production plants with strict food safety standards, good manufacturing practices, and third-party quality certifications. These vitamins are transported to the destination countries in their pure form without mixing in excipients. However, there are exceptions. Vitamins such as vitamin A need to be mixed with gelatin and choline chlorate, requiring the use of corn. Suppliers recognize that vitamins are in transit under their supervision for more than 120 days, enough time to inactivate the Seneca Valley virus and to meet the minimum ingredient quarantine recommended for pig producers. However, in the world market there are suppliers and dealers of vitamins with limited ability to trace the origin of imported products.

This brief is the outcome of a meeting between vitamin manufacturers and pig producers and serves as an example of how the feed and hog industries have collaborated to establish joint biosecurity measures. The complete document can be viewed here (pdf).