Mistakes at this stage can lead to major economic losses to the producer, so they should always be included in the critical control points for feed mills.

Receipt

The process of receiving raw materials begins with the quality requirements and specifications, a document with the expected characteristics- from organoleptic to physical-chemical. This serves to establish with the suppliers the particularities of the raw materials to be purchased, prices, discounts in case of non-compliance, etc. At the time of reception, it will serve as a road map indicating the control points to be taken into account.

The farm or feed mill's first contact with the incoming raw material is extremely important; it is where we begin to verify its quality and, based on that, define its use, forming a strategy according to the category of the animals.

Table 1. Quality specification: Degummed soybean oil

| Organoleptic parameters | ||

|---|---|---|

| Parameter | Standard | Analysis frequency |

| Color | Lovibond yellow 38.0 red 4.2 (yellowish orange) | Each entry |

| Odor | Pleasant, absence of musty odor | Each entry |

| Appearance | Characteristic appearance | Each entry |

| Physical-chemical parameters | |||

|---|---|---|---|

| Parameter | Minimum | Maximum | Analysis frequency |

| Acidity (%) | - | 0.50 | Each entry |

| Moisture (%) | - | 0.15 | Each entry |

| Peroxide value (meq/kg) | 0.00 | 0.00 | Each entry |

| Sediments | - | 0.10 | Each entry |

Sampling

Sampling of raw materials should be done during intake. This is the first link in the chain of the quality control process. If it is done incorrectly, the laboratory results will not be reliable, nor will the correct decisions be made, causing major economic losses to the producer.

The objective of the sample is for it to represent the entire lot in a small portion. To achieve this, it is essential to have a sampling protocol and to follow it strictly. The protocol should establish how to sample, who is responsible, and the frequency.

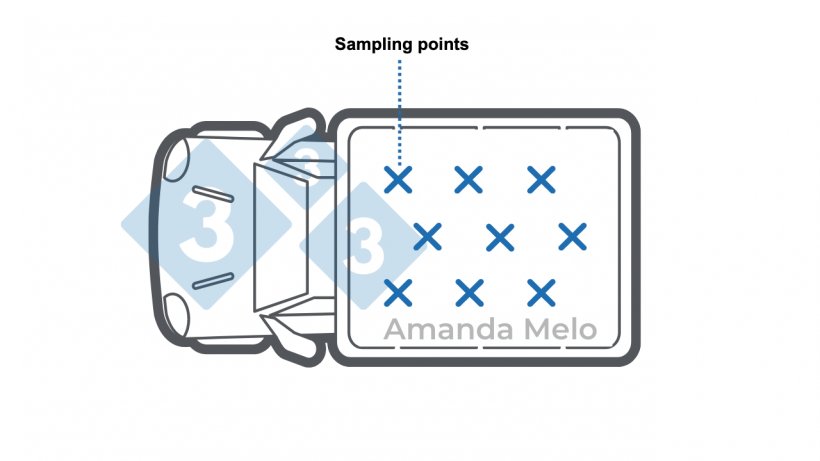

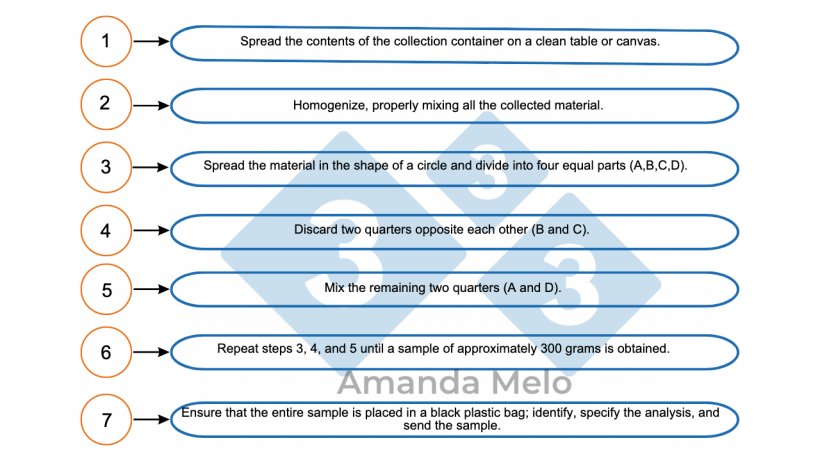

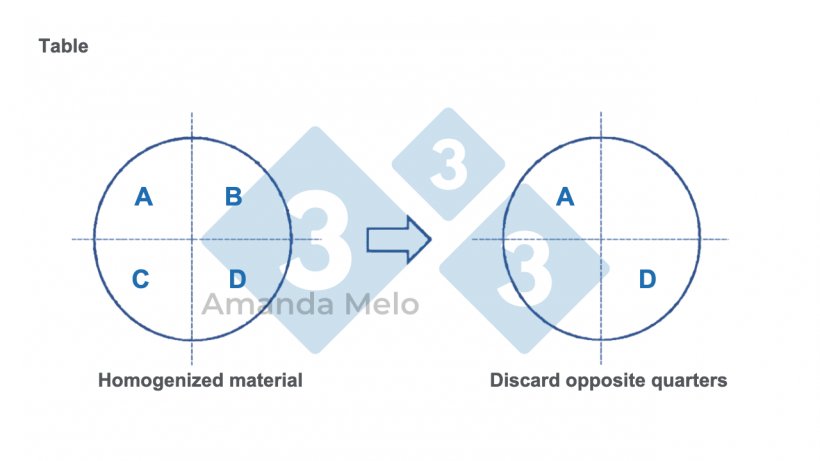

For bulk raw materials, for example in hopper trucks, it is necessary to have a long grain probe and introduce it into different points of the load (Figure 1) and pour each sampled point on a table to visualize the different parts of the whole. Finally, make a pool with each point, quarter the sample (see Figure 5), and send the final sample to the laboratory to conduct the corresponding analyses.

Figure 1: Schematic of the points to sample with a probe on a truck with bulk grains.

In the case of hooper silos, in order to get a representative sample, it is recommended to recirculate the material and, through an opening that allows sampling, collect small fractions of the product throughout the recirculation time.

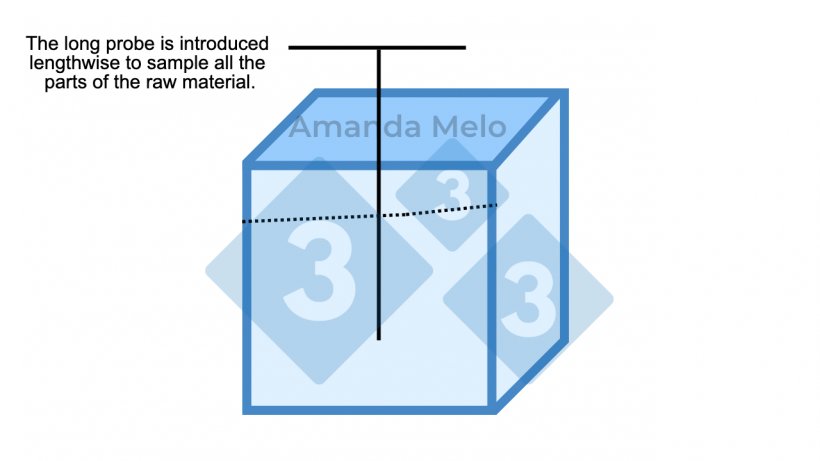

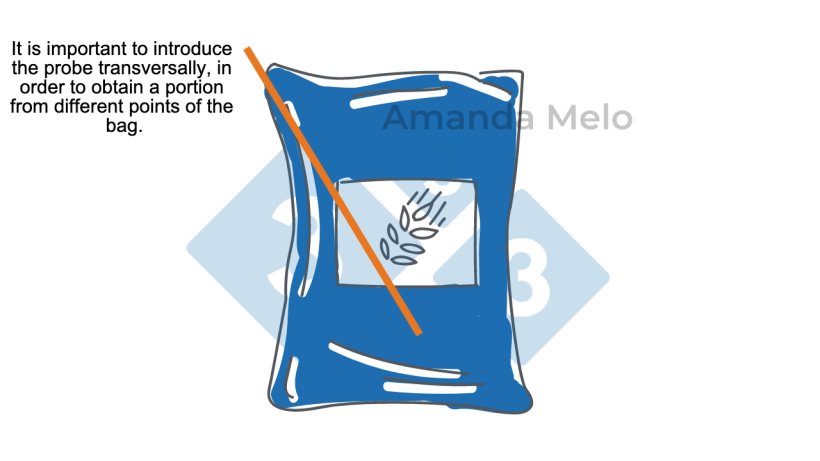

For raw materials in bags or big bags, it is normally recommended to randomly sample 10% of the total number of packages, make a pool with each sampled package, quarter them, and send it to the laboratory (Figures 2 to 5).

Figure 2: Diagram of sampling points in a big bag with a long probe.

Figure 3. Diagram of bag sampling with short probe.

Sampling vegetable oils, if they come in hopper trucks, should be done by taking small aliquots throughout the unloading time. If they come in tanks, randomly sample 10% of the total number of tanks.

In summary, the most important thing when sampling raw materials is not to lose sight of the fact that the total must be represented in a small portion and to use your judgment to achieve this on a case-by-case basis.

Figure 4: Step by step of how to quarter a sample.

Figure 5. Sample quartering diagram.

Storage

In the storage stage, the objective is to maintain the quality with which the raw materials arrived at the plant. The deterioration of quality due to errors at this point may represent direct economic losses due to confiscation or indirect losses due to a drop in the production performance of the animals that consume it.

Generally, grains are stored in hopper silos. In this type of storage, it is very important to take into account the previous cleaning of the grains, since organic impurities can accelerate deterioration or contain seeds that are toxic for pigs (e.g. Datura ferox), besides accumulating dust inside the silos, which increases the risk of fire and pest infestation. Physical contamination with metal fragments, stones, etc. can damage distribution lines, silos, and mills. In addition, it is very important to control the moisture of the grains when they arrive at the silo, because the higher the moisture, the faster they will spoil.

Another point to note is the characteristics of the silos used. For storage longer than 30 days, it is important to have a re-circulation and ventilation system, as well as internal temperature control. It is also essential that the design of the silo allows for proper cleaning and minimum dust accumulation. Also, it is important not to neglect proper upkeep in order to prevent leaks, as well as to have well-adjusted equipment to prevent losses.

Products in bags or big bags must have a specific storage area with a floor, ceiling, and walls that are in good condition, along with good ventilation, protection from light, and that they are free from humidity. They should always be on pallets, with a minimum distance of 20 cm from the walls, to prevent moisture and pests.

For both bulk storage (silos) and bagged storage (warehouses), it is critical to have a program for cleaning and disinfection of spaces, as well as comprehensive control of pests (insects, rodents, birds) that can be vectors of diseases and also accelerate the process of spoilage and loss of quality of raw materials.

At this stage, it is essential to understand and respect FIFO (First In, First Out), i.e., what enters the warehouse first is the first thing that should be consumed, thus avoiding storing expired products. It is therefore necessary to keep the warehouse tidy and clean and to correctly identify and record all raw materials arriving at the establishment (Figure 6).

Figure 6. Critical points of storing raw materials.