On most French farms, the finishing pig barn environment is managed by a dynamic ventilation system based on maintaining an ambient temperature that favors animal comfort and optimal zootechnical performance in terms of weight gain and feed conversion. Numerous studies have been conducted on the influence of temperature on finishing pig performance, which has led to the almost universal introduction of a set point temperature of around 22 °C in finishing barns, a temperature close to thermoneutrality.

In northern Europe, some countries such as Denmark and the Netherlands implement set temperatures around 18°C, stating the aim is to maintain animal performance and, above all, reduce ammonia emissions.

France has committed at the European level to reduce its ammonia emissions by 15% by 2030 compared to 2005. With barns over 20 years old managed by farmers 49 years old on average, it is necessary to study solutions for reducing emissions that do not require structural modifications and that can be adapted to existing facilities.

This study aimed to analyze the effect of implementing ambient temperatures below thermoneutrality on both the zootechnical performance of finishing pigs and their environmental performance (gaseous emissions and slurry composition and volume).

For this purpose, a trial was carried out at IFIP's experimental station in Romillé. IFIP engineers designed a temperature-controlled unit to maintain a constant ambient temperature throughout the finishing period, making it possible to study the influence of temperature on the pigs' zootechnical and environmental performance.

For the needs of this study, three temperature levels were used: 16, 18, and 22°C. In parallel, finishing pigs were housed in a conventional finishing room with a fixed temperature of 22°C.

- Regarding the monitoring of zootechnical performance, the animals in the rooms that participated in the study were weighed individually at entry, during the changeover to finishing feed, and at slaughter to calculate the animals' average daily gain (ADG). Feed consumption per pen and water consumption per room were recorded and, together with weight gain, were used to calculate the feed conversion ratio (FCR).

- For the environmental results, the concentration of ammonia (NH3), nitrous oxide (N2O), and methane (CH4) was measured semi-continuously in each of the rooms in the trial. The volume of slurry was also measured at each animal weighing and samples were taken at the same time to determine the effluent composition for each temperature range.

In the temperature-controlled unit, the mean ambient temperature reached the set targets, i.e., 16, 18, and 22°C. In the control room, the target temperature was 22°C, and the mean room temperature was 26.3±1.4°C.

The zootechnical performance of the pigs kept in lower temperature conditions did not show statistically significant differences in slaughter weight, ADG, or carcass quality. Statistical analysis of the FCR was not possible, but only the 18°C room had a lower mean value than the other three (-0.17 points).

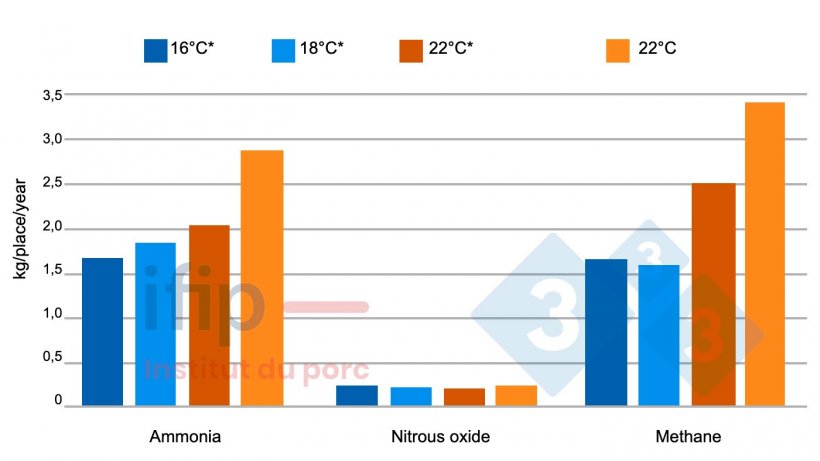

Ammonia emissions from the rooms at 16 and 18°C were statistically significant compared to those of the reference room at 22°C (-42% and -36% respectively for 16 and 18°C). Methane emissions were reduced by more than 50% for the rooms at 16 and 18°C in the temperature-controlled unit. In contrast, no effect was found for nitrous oxide (N2O).

Gaseous emissions as a function of temperature. *Constant temperature applied in the temperature-controlled unit.

Exposing the pigs to constant cold temperatures throughout the entire finishing period reduced their water consumption and consequently decreased the volume of slurry produced during finishing (-25%).

Reducing the ambient temperature in finishing barns is entirely feasible, regardless of how old the facilities are and their configuration. Although confirmation would have to be made on a larger sample of animals regarding the zootechnical performance aspect, this practice would allow many farms to reduce their contribution of gaseous emissions.