We went to visit a farm where the sows are "free" in the farrowing room. It is a purebred multiplication farm that produces weaned piglets. It has about 730 sows and runs three-week batches. All breeding animals are purebred: Large White and Landrace. The barn is newly built and has been operating with this system since 2018. It is located in Emilia Romagna, Italy, at an altitude of 500 meters, with a broad temperature range (from -10°C in winter to 35° in summer). We asked one of the partners (Dr. Repetti) of the company ITACA Soc. Agr. a r.l, and the person in charge (Giuliano) some questions in order to better understand the system.

Figure 1. View from outside the farm.

Figure 2. Exterior fence.

Figure 3. Loading bay.

Dr. Repetti, why did you design farrowing rooms with loose sows if you do not sell pigs directly for slaughter nor are part of a supply chain focused on welfare, but rather on genetic production?

The idea arose in 2016. We wanted to make an investment that would take into account the new provisions for animal welfare, which, in pig farming, will always be a determining factor in the future. Investments are based on a time projection of a couple of decades, so it was decided to adopt this solution that, as the changes in regulations hint at, will end up being mandatory. There is also the intrinsic ethical aspect of livestock farming, which has convinced us that it is the duty of our sector to adopt systems that are increasingly more respectful towards animal welfare, also for the sake of transparency towards the consumer and society in general.

What were the first challenges you encountered?

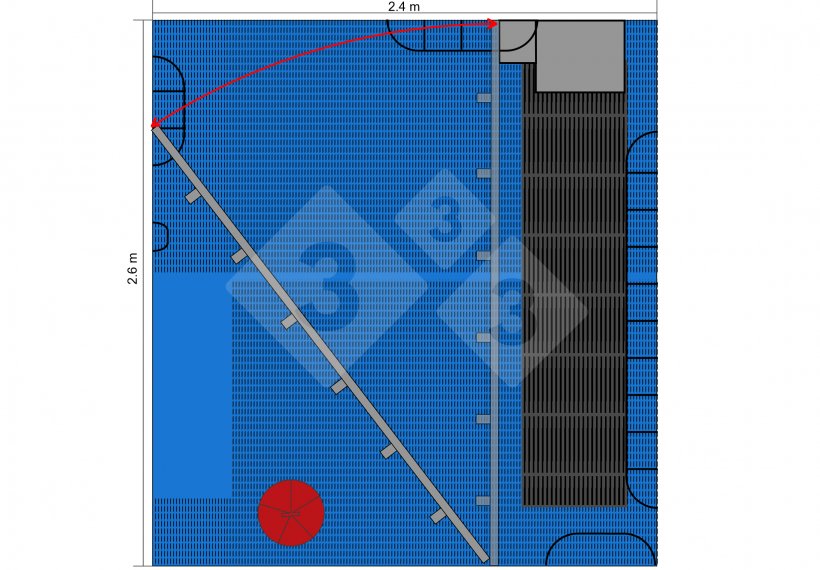

Repetti: First of all, it must be said that in 2016 there was not much experience with this type of facility and we opted for a farrowing pen with a design inspired by the experience of northern European countries. Over time, and based on the experience we were gaining, we made some changes. Already in the initial set-up we made some modifications related to farrowing care and we moved the feeder, which was initially on the aisle side, to the wall side. We are currently moving the entire "crate" inside the pen to a slightly diagonal position by installing a second fixed side panel.

Giuliano: We prefer to prioritize farrowing assistance since, being a farm with a high health status with an internal microclimate management system (we also control the maximum temperature), we do not have to modify the feeding curves of individual sows, nor clean the feeders of leftover feed, so we do not need frequent access to the feeders. A critical problem with the current layout that needs to be resolved is the excessive distance between the nest and the rear end of the sow, which increases the risk of crushing when newborn piglets tend to stay close to the mother. Another critical point, which we would like to correct by installing a second fixed panel at least 40 cm from the farrowing pen wall and, consequently, moving the entire crate (we have already done this in some pens and it seems to work), is the problem of colostrum intake, because accessing the udder is difficult when the sow lies down against the side of the crate with her legs towards the wall.

When do you confine the sow?

Giuliano: When they enter the farrowing room, we leave them crated. Contrary to what we expected, when let out before farrowing, the sows were more agitated and tended to slip on the plastic slat when there was a non-slip metal slat in their crate. At this stage, they are calmer in their crate. We have done several tests: letting them out at 5 days, at 10 days, and more. Finally, we chose to let them out after the 11th day. We do not let them out earlier because it is easier to capture the piglets with the crate closed and day 11 is the day when we identify the future breeding females and boars.

How do you clean the pen?

Giuliano: Before farrowing and the day of farrowing the area behind the sow is cleaned. After that.. nothing more. The piglets make the feces fall down the slat when they step on them and it doesn't get dirty because there is plenty of space. At weaning the pen looks washed. There is nothing left, the sow and the heavy piglets do the cleaning job.

How do you manage the temperature in the summer?

Repetti: We have taken special care with this aspect. We have installed roof coolers, which are placed at the apex, which corresponds to the central aisle; this cold air enters the rooms through the air vents. We have found that, in the height of summer, with outside temperatures above 35°C, we reach maximums of 25-26°C. It helps that the farm is about 550 m above sea level, which means that the air has a low enough relative humidity for our cooling system to be efficient. In addition, the sows, when they are loose, change places and look for the coolest surfaces or those with the most air circulation. Another important factor is the structure's high degree of insulation and the thermal inertia of the concrete.

Have you encountered any issues with vaccinating sows or treating piglets?

Giuliano: Not at all. We use a long syringe and there are no problems, on the contrary, the loose sows are very calm. We also treat the piglets without problems entering the pen; if necessary we could also confine the sow for specific handling procedures.

How is the production data from the farrowing room?

Repetti and Giuliano: Unfortunately, we do not have previous data; the farm was newly built and started with this system. The average born alive and piglets weaned from the last 6 months (January-June) are 13.8 and 12.4 respectively. Remember, all animals are purebred and we are convinced that these data can be improved with pen design modifications. Weaning weights range from 7.5 to 8 kg at 27 days of lactation on average. Piglets that suckle unhindered get more milk and, as a consequence, the sow also produces more: all teats are available and stimulated. We have uniform weaning weights. We don't even use nurse sows. After evening out the litters we wean the biggest piglets from the sows with the most piglets at 21 days, but this does not exceed 5% per batch in any case. These piglets then go to a free pen and if we do not have any available, they go to the weaning area of the gilt development unit (we do self replacements).

Is it more complicated to wean sows and clean the farrowing room? Does it take longer? How long?

Giuliano: I dare say that weaning is even faster. More than 50% of the sows come out on their own (not to mention the piglets!). It takes 4 people 1 hour to wean and bring 90 sows to gestation. For each weaned batch, which corresponds to 4 farrowing rooms - about 96 sows - it takes about 30 hours to wash the pit (only 1 operator), as they are shallow (30 cm) and very easy to clean. In the weaning area, several groups are separated to be loaded the following day (breeding female weaners, breeding male weaners, non-tattooed not selected weaners, and self-replacement weaner gilts that remain on the farm). We mix them in the aisle with all the pens open, so they can move around and socialize (in fact, they fly onto the truck the next day!)

From what I see in your data, farrowing room mortality is 10.1% (the last 6 months) and, from what you tell me, mortality after 15 days of life is practically zero. Normally there are still considerable losses between 15 days and weaning on conventional farms. What do you think is the reason for the lower mortality at this stage?

Giuliano: I do not have the mortality per day of lactation, but I can tell you that in each batch of about 80 farrowings, a maximum of 3 to 5 older piglets die per batch. In addition to the good health status of the farm (PPRS negative), which allows us to have very few losses due to streptococcus or coli, the fact that the pen is very spacious eliminates mortality by crushing. Traditional farrowing crates are not adapted to the increase in the number of piglets born nor to the increase in age at weaning, which implies heavier piglets, which contributes to more crushing, even of large piglets.

We could joke that 40 years ago we invented farrowing crates to prevent crushing and now we are getting rid of them... for the same reason!