Introduction

Rice (Oryza sativa) is an herbaceous cereal of the Poaceae family originating in Asia but is currently cultivated all over the world. It is the most produced cereal in the world, ahead of corn and wheat, and its production is mainly destined for human consumption. There are many varieties, although most are classified by type or organoleptic characteristics. The most common categories are identified by grain type, with short or round grains and long grains being the most common.

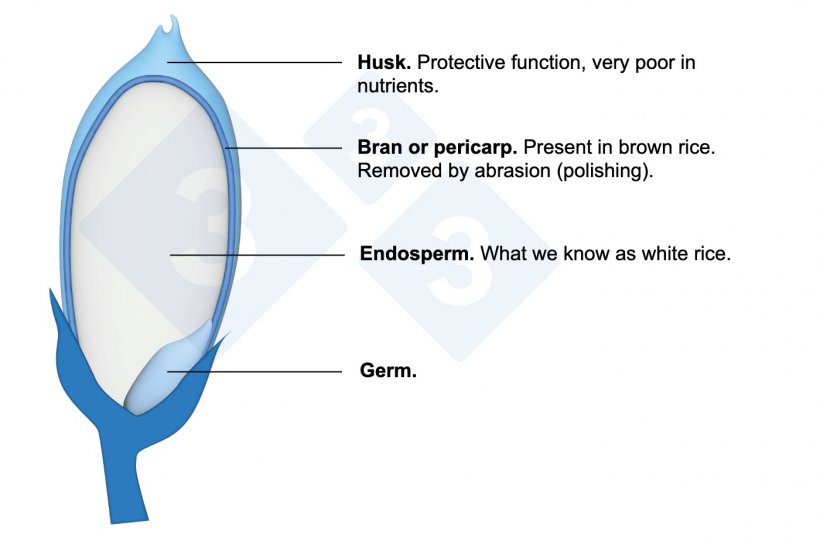

In the grain of rice, the ventral part, where the germ is located, and the dorsal part are well distinguished; the pericarp is wrapped by dense cellulosic-fibrous tissue (husk that represents between 20 and 22% of the weight of the freshly harvested grain). This husk is a hard layer that protects the grain and has high lignin and SiO2 content and is very poor in nutrients. Like most cereals, it has a pericarp, which is the wall that gives brown rice its name once the rice grain has been hulled. This pericarp represents about 2% of the total hulled grain. After elimination of the bran (pericarp) by physical processing (polishing), two fractions remain: the germ and the endosperm. Disregarding the proportional weight of the germ, a final fraction of endosperm remains, representing between 73-75% of the rice grain.

This remaining fraction contains the aleurone layer, which is the outer layer of the endosperm, composed of starch granules and a certain content of proteins and fats. It also contains the white endosperm, which is basically composed of starch granules. From the industrial point of view, it is the part that is marketed as white rice following the rice grain polishing process.

As a co-product of the rice industry dedicated to the preparation and processing of rice grains for human consumption, we find different fractions available that are commonly used for animal feed (rice bran, broken rice, etc.). Among these fractions, broken grains, known as broken rice, represent the major ingredient as a high-quality energy source due to their high starch content (>80%) and negligible content of anti-nutritional factors, which make them an interesting ingredient for feeding young animals and, in particular, in diets for weaning piglets (milk replacers and prestarters). Furthermore, compared to other energy sources, the mineral fraction has a good digestibility. In spite of its low protein content (7.5%), the lysine content is acceptable (3.8%) with good amino acid digestibility in pigs (estimated ileal digestibility coefficient >95%). Polished rice is a highly digestible and palatable ingredient for piglets and heat processing (extrusion, cooking, or steaming) can further contribute to the improvement of intestinal health. The use of brown or partially processed broken rice is not recommended because the fat fraction (basically linoleic acid) becomes rancid very quickly causing palatability to decrease greatly for young animals. Even so, there are different presentations, semolina and rice flours with different amounts of fiber on the market.

Comparative study of nutritional values

The systems used in the comparison are: FEDNA (Spain), CVB (the Netherlands), INRA (France), NRC (United States), and Brasil (Brazil).

| FEDNA | CVB1 | INRA1 | NRC1 | BRASIL | |

| DM (%) | 87.2 | 88.5-91.2 | 87.4 | 89-87.9 | 88.4 |

| Energy value (kcal/kg) | |||||

| Crude protein (%) | 7.5 | 7.8-13.9 | 8-7.1 | 7.9-8.0 | 8.34 |

| Ether extract (%) | 1 | 0.8-17.6 | 1.2 | 1.3-1.4 | 1.2 |

| Crude fiber (%) | 1.0 | 0.7-6.0 | 0.5-1.1 | - | 0.6 |

| Starch (%) | 71.8 | 72.5-28.5 | 75.9-77.1 | 75.2-83.6 | 74.9 |

| Sugars (%) | 1.8 | 0.9-4.8 | 1.3-0.4 | - | - |

| DE growth | 3560 | - | 3670-3540 | 3565-3681 | 3572 |

| ME growth | 3510 | - | 3680-3460 | 3511-3627 | 3489 |

| NE growth | 2780 | 2727-2646 | 2860-2810 | 2778-2881 | 2778 |

| NE sows | 2780 | 2727-2646 | 2860-2810 | 2778-2881 | 2811 |

| Protein value | |||||

| Digestibility of crude protein (%) | 88 | 95-66 | 90-89 | - | 85.8 |

| Amino acid composition (% CP) | |||||

| Lys | 3.8 | 4.20 | 3.70 | 3.80-4.45 | 3.62 |

| Met | 2.4 | 2.10 | 2.30-2.40 | 2.28-3.18 | 2.42 |

| Met + Cys | 4.67 | 4.30 | 4.70 | 1.84-2.73 | 4.49 |

| Thr | 3.51 | 3.70 | 3.40 | 3.29-2.92 | 3.34 |

| Trp | 1.3 | 1.10 | 1.10 | 1.27-1.40 | 1.21 |

| Ile | 3.7 | 3.70 | 4.00 | 4.30-4.07 | 4.07 |

| Val | 5.47 | 5.50 | 5.90 | 6.20-5.34 | 5.71 |

| Arg | 7.4 | 7.80 | 8.20 | 6.58-5.59 | 7.34 |

| Standard ileal digestibility (% CP) | |||||

| Lys | 90 | 94-62 | - | 77-89 | 84.8 |

| Met | 96 | 95-71 | - | 85-87 | 86.5 |

| Met + Cys | 92 | 92.5-61.5 | - | 75-82 | 79.8 |

| Thr | 90 | 93-61 | - | 76-85 | 82.4 |

| Trp | 93 | 93-75 | - | 77 | 82 |

| Ile | 96 | 96-68 | - | 81 | 87.8 |

| Val | 93 | 95-66 | - | 78-86 | 85.5 |

| Arg | 92 | 96-77 | - | 89-93 | 92.8 |

| Minerals (%) | |||||

| Ca | 0.04 | 0.01-2.49 | 0.01-0.05 | 0.04-0.09 | 0.05 |

| P | 0.1 | 0.09-1.70 | 0.2-0.21 | 0.21-0.34 | 0.18 |

| Phytic P | 0.06 | 0.08-1.53 | 0.16-0.12 | 0.14-0.18 | 0.13 |

| Available P | 0.02 | - | - | - | 0.06 |

| Digestible P | 0.01 | 0.01-0.02 | 0.0 | 0.08-0.11 | 0.0648 |

| Na | 0.02 | 0.01 | 0.02 | 0.04 | 0.02 |

| Cl | 0.03 | 0.03-0.04 | 0.01-0.04 | 0.07 | 0.05 |

| K | 0.12 | 0.09-1.00 | 1.49-0.31 | 0.13 | 0.2 |

| Mg | 0.08 | 0.02-0.67 | 0.14-0.15 | 0.11 | 0.08 |

1For the CVB, INRA, and NRC systems, we present the ranges of values (minimum and maximum) resulting from the integration of 3, 2, and 3 different classifications, respectively, which these evaluation systems consider basically according to the physical processing in rice industry and mills (which, according to market availability, are available as ingredients for pig feed).

Unlike the rest of the tables, FEDNA and BRASIL are the only rice evaluation systems that present only one category of rice, as it is the most commonly used for swine feed (broken rice). However, the CVB, INRA, and NRC valuation systems differentiate between qualities that are basically classified by rice milling and differentiated by starch, fiber, and ash content. In this sense, INRA and NRC basically differentiate according to the degree of processing (polishing), which represents the greater or lesser presence of the bran (pericarp), which can also affect the fat and fiber content. On the other hand, CVB, apart from polished rice, considers different flours and semolinas from rice milling and processing in its evaluation system, two qualities that are differentiated by their high content in ash, protein, and ethereal extract as well as by a low starch content. These fractions from rice milling and processing considered rice flours or middlings correspond to the fractions resulting from polishing which have carried over starch and which also contain all the pericarp and germ, hence the higher protein, fat, and fiber values. In addition, the ash content associated with these rice flours usually responds to the incorporation of CaCO3 to facilitate fluidity, handling, and transport in the processing plant and feed mill.

The range of dry matter between evaluation systems is not very variable (CV<1%), with NRC having the maximum value (89% DM) and FEDNA the lowest (87.2% DM), and CVB and BRASIL being intermediate with very similar values (+/-88.5%). In any case, the two rice flours proposed by CVB have the most extreme DM ranges with 91.1% and 92.2%, respectively, which are in contrast to the broken rices, regardless of the degree of polishing.

The average protein content is 7.8%, ranging from 8.34% (BRASIL) to 7.1% (INRA). These values, with so little variation, clearly differ from the high protein contents proposed by CVB for rice flours (CP of 13.7% and 13.9%, respectively), possibly because they contain the germ fraction and part of the aleurone wall. These differences can be practically associated with the type of processing (basically polishing) and reconstitution of fractions in the case of rice flours. A marked inversely proportional relationship is observed between protein or fiber content and starch content (R2>0.95). However, if the rice flours proposed by CVB are not considered, this relationship is insignificant since the polishing process minimizes this interaction.

The variation in starch content (CV=4.75%) largely explains the estimation of the NE content. A slight contribution of the fibrous fraction that negatively affects the energy estimation (R2>0.15) can also be appreciated which, together with the contribution of the fat content due to its high variability due to processing (CV=15%), is determinant in explaining the difference of >150kcal/kg of NE (representing >5%) observed between the different more extreme evaluation systems (2881 kcal/kg; NRC whole grain vs. 2360 kcal/kg; CVB broken grain). While starch content is the most important factor for energy value, it can be observed that, apart from processing and polishing that can affect fiber and fat content, grain quality (whole vs. broken) and the different varieties that may reach different destinations, as is the case for other cereals such as corn, can largely explain these differences in energy value.

In terms of total amino acids, taking lysine (mean 3.9%; CV=7.5%) as a reference, rice has good content despite its limited protein content, which does not show the same variability (CV<5%). The values for the rest of the total amino acids are quite proportional to lysine and even less variable, with the exception of sulfur-containing amino acids (methionine and cysteine) and arginine that present extreme values by CVB and NRC above (+31% sulfur) and below (-22% arginine) with respect to the mean of the rest of the considered titration systems, respectively. The protein and lysine digestibility coefficient presents a range between 77 and 94%, with an average value of 87%, but is basically attributable to the lower value of 77% attributed by NRC as a penalty to broken rice, being the lowest value with respect to the rest of the evaluation systems even at equal product categories.

Recent findings

1. Potential use of ground brown rice for weanling pigs

The effects of substituting corn with ground brown rice on growth performance, immune status, and gut microbiota were studied in weanling pigs. The control pigs were fed a typical diet for weanling pigs based on corn and soybean meal diet (control diet: CON), and the other pigs were fed a formulated diet with 100% replacement of corn with ground brown rice for 35d (treatment diet: GBR). Growth performance, immune status, and gut microbiota of weanling pigs were measured. Growth performance was not affected when corn was replaced with ground brown rice at weaning. Furthermore, immune status and gut microbiota of pigs increased on beneficial microbial communities and reducing harmful microbial communities. Overall, ground brown rice-based diet is a potential alternative to corn-based diet without negative effects on growth performance, immune status, and gut microbiota changes of weanling pigs.

2. Rice as an alternative feed ingredient in swine diets

The aim of the present work is to look for functional alternative ingredients for traditional feed ingredients in pig diets, considering the stress of pigs and their sensitivity to diseases. Although the nutritional quality of rice varies depending on the degree of milling, rice, except whole grains (paddy rice), contains more starch than corn and its structure and granule size are easier to digest than corn. In addition, the fact that rice has fewer non-starch polysaccharides (NSP) and anti-nutritional factors (ANFs) is also effective in improving digestibility and various polyphenols in rice can help modulation of immune responses, which can be beneficial to the gastrointestinal environment and health of the pig. Many studies have been conducted on rice focusing on things such as degree of milling, substitution rates of corn, granule size, and processing methods. Most results have shown that rice can be partially or completely used to replace corn in pig diets without negatively affecting pig growth and production. It was confirmed that the use of rice could reduce the use of antibiotics and pig removal and protect pigs from gastrointestinal diseases including diarrhea.

3. Influence of extrusion of corn and broken rice on energy content and growth performance of weaning pigs

Two experiments were conducted to study the effects of extrusion on the energy content of corn and broken rice and on growth performance of weaning pigs. In experiment 1, the effects of extrusion of corn and broken rice on the values of digestible energy (DE) in weaned pigs were studied. The DE content in extruded corn (17.45 MJ/kg dry matter (DM)) was significantly greater (P < 0.05) by 5.54% compared with that in corn (16.48 MJ/kg DM), while no significant difference in DE content was observed between extruded broken rice (17.66 MJ/kg DM) and broken rice (17.76 MJ/kg DM). In experiment 2, the influence of substituting corn and extruded corn by different proportions of raw and extruded broken rice on growth performance of pigs was evaluated. The inclusion of broken rice in the diets improved growth performance of pigs during the first week and the 2 weeks post-weaning but not thereafter. However, there was no significant difference in growth performance between treatments in other periods.

4. Ileal amino acid digestibility of broken rice fed to postweaned piglets with or without multicarbohydrase and phytase supplementation

Twenty-five weaned pigs were used to determine the apparent total tract digestibility (ATTD) of nutrients, energy, and apparent ileal digestibility (AID) and standardized ileal digestibility (SID) ileal AA digestibility of broken rice (BR), with or without multicarbohydrase (MC) and phytase (Phy) supplementation in weanling pigs. A completely randomized experimental design was used to determine the effects of MC and Phy. Reference diets (RD, 5% casein) were replaced by 30% of BR with or without MC, Phy, or MC+Phy. Standardized amino acid digestibilities of BR, without enzymes, were lower than those values reported in the literature. The MC and Phy improved the digestibility of some nutrients and energy of BR in post-weaned piglet diets.

5. The effects of extrusion processing of carbohydrate sources on weanling pig performance

Three experiments were conducted to study the effects of extrusion processing on growth performance of weanling pigs fed diets based on the effects of various carbohydrate sources (corn, corn-starch, broken rice, wheat flour, and grain sorghum), with or without moist extrusion processing. The three processing conditions were 1) pelleted only (control); 2) corn that was moist-extruded and then the complete diet was pelleted (extruded); or 3) the complete diet was expanded and then pelleted (expanded). Finally, piglets fed pelleted diets containing nonextruded corn (14.5% gelatinization; control) or corn extruded to provide 38.7, 52.7, 64.4, or 89.3% gelatinization. The results obtained indicate that moist extrusion processing of carbohydrate sources has variable effects on growth performance of early-weaned pigs and that the degree of gelatinization does not seem to be a major factor in explaining this variation.

References

FEDNA: http://www.fundacionfedna.org/

FND. CVB Feed Table 2019. http://www.cvbdiervoeding.nl

INRA. Sauvant D, Perez, J, y Tran G, 2004, Tables de composition et de valeur nutritive des matières premières destinées aux animaux d'élevage.

NRC 1982. United States-Canadian Tables of Feed Composition: Nutritional Data for United States and Canadian Feeds, Third Revision.

Rostagno, H,S, 2017, Tablas Brasileñas para aves y cerdos, Composición de Alimentos y Requerimientos Nutricionales, 4° Ed.