The overall prevalence of Salmonellosis in humans across the European Union is decreasing but much of this decrease has been ascribed to reduced Salmonella in eggs and poultry meat. There is now increasing emphasis on the role of pig meat as a source of human infection. The European Food Standards Authority (EFSA) estimates that, across the EU, up to 27% of human Salmonellosis cases may be attributed to pig meat (EFSA 2011), although other published estimates indicated lower rates in the order of 3-15% (EFSA 2010). European law (Regulation EC2160/2003) requires that National Control Plans are implemented in Member Sates and that controls need to be focused at all stages of pig meat production with increased emphasis on livestock production. This article provides a brief summary of the contribution of slaughter, processing and retail to the presence of Salmonella on pig meat. It reviews current control methods and other steps that could be included in the near future.

How big is the problem?

Recent surveys around Europe give a good idea of the prevalence of Salmonella in pigs arriving at slaughter, and on carcases leaving the abattoir, but there is less information on prevalence of Salmonella in pig meat at the retail stage. All stages of the supply chain contribute to the problem: an EU-wide survey found an average of 10.3% of pigs at slaughter harboured Salmonella in ileo-caecal lymph nodes (S. Typhimurium and S. Derby representing 40% and 14% of these respectively) (EFSA 2008). The same survey also studied external carcase contamination and found an average prevalence of 8.3% of carcases with Salmonella on the external surface – however, but only a subset of Member States contributed to this part of the survey. Surveys of the prevalence of Salmonella on pig meat cuts at retail have not been undertaken at EU-wide level but prevalence in Denmark was found to be 4.2% in 2006 (Hansen et al 2010) and similar levels have been reported in other EU States. The prevalence of Salmonella contamination, and number of organisms per positive sample, has been shown by several studies (including Hansen et al 2010) to be higher for butcher shop samples compared to supermarket samples. In Denmark, the potential importance of cutting plants in Salmonella cross-contamination of meat was suggested since a 4-fold increase in contamination prevalence of Butcher shop samples between 2002 and 2006 was linked to a shift in supplier base from direct slaughter house supply towards cutting plants.

How does Salmonella get onto the meat?

The routes of access for Salmonella onto pig meat differs according to stage of processing. At the abattoir, the most important factor is the supply of Salmonella-colonised pigs onto the slaughter line with subsequent contamination of the carcase after scalding and singeing. It is important to note that pigs from Salmonella-free sources can become infected during transport or lairage and also after slaughter (Kirchner et al 2011). Leakage from the anus, gut rupture at evisceration and subsequent cross-contamination of neighbouring carcases by splash, handling, and contact with contaminated surfaces are all important aspects of Salmonella contamination. At the cutting stage through to retail factors such as cross-contamination from handling, from equipment and surfaces are important. Bacterial growth will occur where chill temperatures are not maintained – this can be important at the retail stage and especially in the homes of consumers, since even initially low numbers of Salmonella will proliferate to reach an infectious dose. The Danish study above found that Salmonella positive samples from Butcher shops typically had higher numbers of organisms per gram compared to supermarket retailers, reinforcing this idea.

What is the basis of current controls?

Current controls puts emphasis on a full-chain approach. Food business operators along that chain, from farm to retail, have combined responsibility for the production of safe food (Regulation EC852/2001). Up until the present, farm-level monitoring and controls have been organized at Member State level and, although estimation of serological prevalence on pig infection by meat juice ELISA is widespread, different States have used different test methodologies so comparison of data is difficult. Producers are required to declare the results of Salmonella testing to abattoirs as part of Food Chain Information under food hygiene legislation. Abattoir-level controls fall under Hazard Assessment of Critical Control Points (HACCP) procedures also required under food hygiene law. These include scalding, dehairing, singeing, anal bunging, and the use of methods to avoid contamination at evisceration. Hygiene steps are taken to minimize contamination from splash and direct contact with contaminated equipment or hands. Hot water carcase rinsing is an effective, but under utilized, step that significantly reduces carcase contamination. Finally, rapid chilling down to <7C is a critical step in stopping bacterial proliferation. Similar, HACCP based, principles are applied to Salmonella control at the cutting, processing and retail stages. Microbiological sampling is required by law at all of these stages as an indication of process hygiene and the presence of Salmonella should trigger review and amendment of hygiene practices.

What lies in the future?

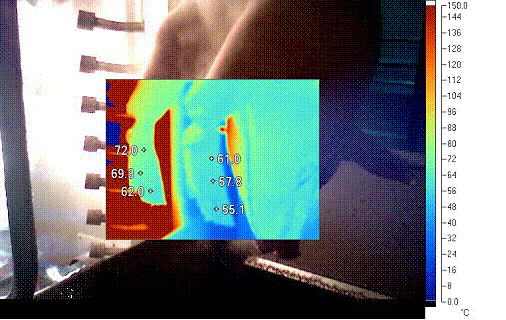

Policy for Salmonella control in pig meat is at a cross-roads. Based on successes achieved in the poultry industry, legislators are driving for enhanced efforts at farm level to reduce the prevalence of Salmonella in pigs arriving for slaughter. Consequently, regulation EC2160/2003 requires introduction of National Zoonosis Control Plans for target-based reduction of Salmonella in the EU pig population at farm level. However, cost benefit analysis suggests that the cost of on-farm controls will far outweigh the economic benefits to human health (EFSA). In addition, research shows that drastic reductions in the prevalence of Salmonella-positive pigs would be needed to obtain a significant reduction in the prevalence of Salmonella positive carcases (Baptista et al 2010) and also that there is a significant abattoir dependent effect (i.e. variation between hygiene standards at different abattoirs) on contamination, irrespective of the colonization status of incoming pigs. The value of focusing on enhanced abattoir-based controls such as hot water carcase rinsing is supported by cost benefit analysis (Goldbach and Alban 2005). Also, research has led to the development of an abattoir hygiene risk reduction tool that identified key areas for future focus in reducing contamination at slaughter (Howell and Hutchison 2009). The steps that could be exploited include anal bunging before scalding, optimization of scalding, optimization (by thermal imaging) of singeing to ensure all parts of the carcase are adequately heated, decontamination of de-hairing machines, and blast / rapid chilling. Moving along the food-chain to cutting and retails stages, the evidence described above indicates that there is opportunity to tighten up on hygiene steps and temperature control, particularly in butcher’s shops.

Ultimately, consumers must also play their own part in risk management by understanding the importance of storing, preparing and cooking pig meat (just like any other meat) in a way that minimizes bacterial growth, avoids cross contamination of cooked and uncooked foods, and destroys residual Salmonella through thorough heating.

Figure 1. A thermal imaging camera can be used for optimization of singeing to ensure adequate heating of all parts of the carcase, especially the front end – where Salmonella load is greatest. Photo is supplied by Hutchison Scientific Ltd.