The growing demand for animal-derived products calls for a more efficient utilization of key resources. For this reason, it is necessary to constantly re-evaluate the nutritional requirements of animals and improve feeding systems to minimize waste. In recent years, several research groups have been working on so-called precision feeding systems. These systems aim to feed a group of animals or the individual with a specific feed composition with the objective of improving the efficiency, profitability, and sustainability of livestock production (Pomar and Remus, 2019). However, the use of these systems in a generalized way would currently imply an additional cost that could not be afforded by conventional livestock farming.

It is well known that the nutritional requirements of finishing pigs basically depend on their lean tissue growth potential as well as feed intake capacity (van Milgen et al., 2008). For this reason, differentiated feeding of groups of animals with different lean deposition or intake potential is a feasible option between conventional phase feeding and electronic precision systems. The application of this feeding system involves grouping pigs according to the criterion that leads to maximum differentiation in nutritional requirements. In the following articles we will analyze feeding differentiated by live weight (LW) at the start of the growing phase, (30-60 kg LW) and by sex in the finishing phase (70-100 kg LW).

Differences due to live weight variability

The variability of live weights in all-in all-out systems is an inconvenient reality because of its negative effects on the timing to empty the barn, as it reduces the number of cycles per year and represents an inefficiency for phase feeding systems. Previous studies have shown that small pigs benefit from differentiated feeding, as they routinely have a lower consumption of starter feeds (López-Vergé et al., 2018). Table 1 shows the differences in intake capacity and growth in pigs classified into three categories according to their LW. We can see how the lower intake capacity of the small ones is the reason for the increase in the differences in LW throughout finishing, since in the same period of time they are even more efficient.

Table 1. Effect of weight category on productivity from 28 to 63 kg average LW (Aymerich et al., 2020). Distinct letters indicate significant differences. ADG = average daily gain, ADC = average daily consumption, FCR = feed conversion ratio. SEM= standard error of the mean.

| Small | Medium | Large | SEM | P-value | |

|---|---|---|---|---|---|

| Starting weight, kg | 23.4c | 27.5b | 32.1a | 0.13 | <0.001 |

| ADG, kg | 0.683c | 0.750b | 0.807a | 0.017 | <0.001 |

| ADC, kg | 1.34c | 1.49b | 1.66a | 0.020 | <0.001 |

| FCR | 1.96c | 2.00b | 2.06a | 0.018 | <0.001 |

Differential response to dietary lysine

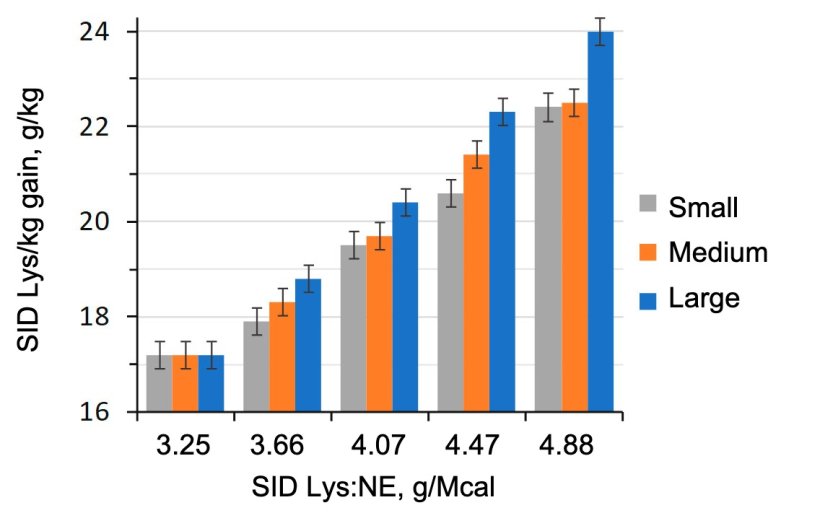

The same study showed a differentiated response mainly between small and large pigs to increased dietary lysine (SID Lys). As an example, small pigs showed a greater increase in growth (ADG) and decrease in feed conversion ratio (FCR) when increasing the SID Lys to net energy ratio (SID Lys:NE). Similarly, SID Lys utilization for weight gain was similar in diets with a low lysine to energy ratio, but increased linearly more in large pigs than in small and medium sized pigs (Figure 2). Therefore, pigs in these two weight categories were able to utilize more lysine in diets with high amino acid concentration.

Figure 1. Effect of dietary lysine to energy ratio in finishing pigs (28-63 kg LW) sorted by starting weight. (Aymerich et al., 2020).

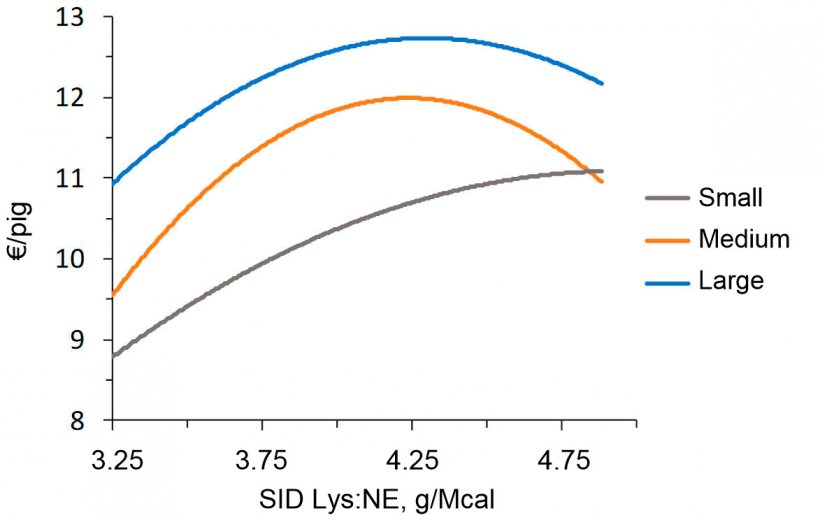

Data from the first 26 days of the same trial were used to model Income over feed and facility (IOFFC; Menegat et al., 2019) in a fixed-time simulation. Figure 2 shows how the revenue from pig sales gradually increases in small pigs up to the diet with the highest SID Lys:NE ratio (4.88 g SID Lys/Mcal NE), while in the medium and large categories it peaks around 4 g SID Lys/Mcal NE and thereafter there is a drop.

At this stage (30-60 kg LW), a differentiated feeding strategy would consist of feeding a diet of ≥4.5 g SID Lys/Mcal NE to the smallest third of pigs and a diet of 4.0 g SID Lys/Mcal NE to the remaining pigs, increasing the profit per small pig by €0.5-1.0.

In summary, differentiated feeding for small pigs within a finishing batch allows us to maximize the revenue from the sale of small pigs by reducing the difference in LW between them and the larger pigs. In addition, we can maximize revenue for the larger pigs by decreasing feed cost by using diets with lower SID Lys concentration as they respond more narrowly to the increased lysine to energy ratio. The implementation of these types of measures entails investments such as the installation of an extra feeding line for part of the pens, which is a moderate cost compared to precision feeding systems.

Figure 2. Economic modeling (IOFFC) of the effect of lysine:energy ratio in finishing pigs (28-63 kg LW) classified by their starting weight (from Aymerich et al., 2020)