Solid/liquid separation equipment allows the separation of slurry into two phases, a solid and a liquid fraction, with the objectives of improving management, facilitating the transport of the solid fraction, enabling treatment processes for each phase separately, or reducing emissions from the phase that is volumetrically greater- the liquid phase- as it contains a lower concentration of organic matter, or enabling precision irrigation systems with the liquid phase.

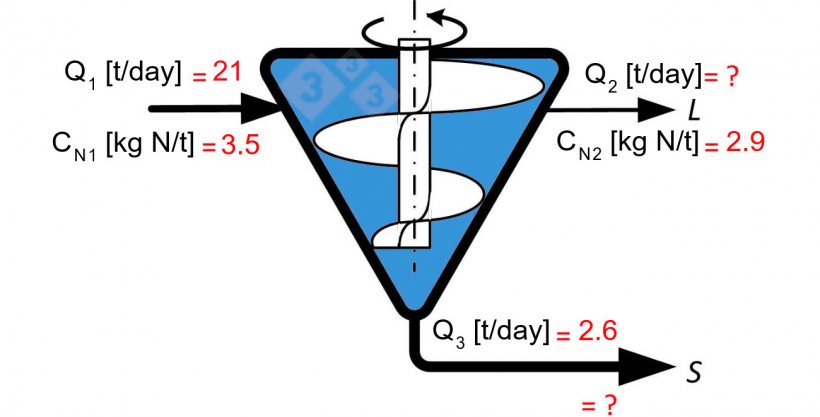

The efficiency of a separator is quantified by at least two values: the separation efficency of flows rates (ηQ) and the separation efficiency of mass flows rates such as nitrogen (ηN) or phosphorus (ηP). Each of these efficiencies is defined as the proportion of the mass flow from the input that is transferred to the solid fraction; the remainder goes to the liquid fraction, since the principle of mass conservation must be fulfilled. To illustrate these concepts, the nomenclature in Figure 1 will be used below to calculate the unknown values from hypothetical measured data for a given equipment and slurry.

Figure 1. Diagram of screw press, indicating the nomenclature and data used to calculate efficiency.

Q2 = Q1 - Q3 = 18.4 t/d ⇒ ηQ = 2.6/21 = 0.124 → 12.4%

Q1CN1 = Q2CN2 + Q3CN3 ⇒ CN3 = (Q1CN1 - Q2CN2)/Q3 = 7.75 kg N/t

ηN =Q3CN3/Q1CN1 = 0.274 → 27.4%

If the separated solid fraction is exported, in this example, 27.4% of the nitrogen in the slurry is exported, with a concentration of 2.2 (what is exported has a nitrogen concentration 2.2 times higher than the original concentration). Obtaining high levels of concentration (by combining several separators in a series, for example) implies reducing the overall separation efficiency, i.e., less nitrogen percentage is exported, but it is more concentrated, which may be of interest depending on the subsequent use of the solid fraction.

Table 1 shows the efficiency ranges for the three main types of S/L separation systems. By using coagulants (iron or aluminum salts) or flocculants (organic polymers), the efficiency of the equipment can be improved, although this effect is not possible to generalize and depends on the slurry composition. When the slurry is very dilute, separation with flocculants can be improved by flotation through the addition of air bubbles. Coagulants can be replaced by an electrocoagulation system, in which an electric current solubilizes an electrode, usually iron, to achieve the same particle aggregation effect.

Table 1. Efficiency ranges (% of the indicated parameter transferred to the solid fraction), of mass flow rates (Q), nitrogen (N), and phosphorus (P), for different types of solid/liquid separators.

| Separation system | Separation technology | Separation efficiency (%) | ||

|---|---|---|---|---|

| ηQ | ηN | ηP | ||

| By particle size and gravity | Static or rotating screen, mesh, drum screen, decanting | 10-20 | 15-25 | 15-40 |

| By pressure | Screw press, filter press | 10-25 | 15-30 | 20-80 |

| By centrifugation | Centrifuge | 10-20 | 25-50 | 40-80 |

In general, centrifugation is more efficient than separation by pressure, and the latter is more efficient than separation by size, even though in Table 1 the wide ranges of the efficiencies do not demonstrate this. The reason is that the efficiency depends on the composition of the slurry and, above all, on its age at the time of separation; the less old the slurry the higher the efficiency, being higher when the slurry is separated a few hours after its excretion. This is due to the fact that in the decomposition processes, which start almost immediately, many solid compounds are solubilized that can no longer be separated by mechanical methods. It is difficult for a supplier of this equipment to guarantee a certain efficiency since this depends more on the previous handling of the slurry than on the quality of the separators.

To improve separation efficiency, the cooperative Cooperl (France) developed the TRAC© system (Traitement par RAclage Cooperl), which consists of separation in the pits under the slats every few hours. A system of scrapers circulates upwards on the floor of the pit, which has a slight slope; the solid fraction is compressed upwards while the liquid drains downwards so that the solid fraction is obtained on one side of the barn and the liquid on the other. Nitrogen separation efficiencies of around 55% have been measured with this system, efficiencies not achievable with conventional separation systems. This system has the additional advantages of fewer respiratory problems, lower mortality rates, and higher productivity, due to the prevention of decomposition processes and gas emissions in the barn itself.

It is interesting to note in Table 1 that the phosphorus separation efficiency is usually higher than that of nitrogen. This implies that in the liquid fraction the N/P ratio will be higher than in fresh slurry, and that this ratio will be more suited to the demand of many crops.

Figure 2. Static screen type solid/liquid separator.

What role does S/L separation play in situations with no excess?