Since I published the first article in 2007 about planning of pig units in 333, many design parameters have changed. Animal welfare has become even more important in directing design of pig facilities and development of new technology. Moreover, genetic evolution has resulted in huge variation in reproductive output and growth between different breeds which must be considered while designing facilities. The nutritional needs of high productive breeds will lead to further developments of feeding systems that might finetune the feed allowance for such animals. Lately, demand for and shortage of labour has led to increased automation of certain labour tasks such as cleaning that might be handled to some extent by robots. Some of the main changes affecting design of pig facilities are presented below.

Animal welfare

From 2003 until 2013 the EU legislation regarding housing of gestation sows led to intensive development of new housing methods of pregnant animals. Most development happened in EU countries while North America has followed slowly without legislation. Asia and South America are still newcomers to group-housing of sows but financial institutions such as the World Bank are starting to demand that sows are housed in groups to provide finance.

Several European countries have moved beyond the general EU requirements. Thus, in some North European countries, sows must be loose or in groups in the whole period from weaning until the next farrowing with only a few days in stalls permitted. Moreover, loose housed sows in the lactation period are now required in Germany in new facilities and in several countries new farms already included this system. Last year EFSA’s (European Food Safety Authority) panel on Animal Health and Welfare published a large report on the welfare of pigs on farm in the EU suggesting that sows be loose housed in the future. If the EU Commission is following the recommendations a lot of changes in future legislation regarding housing and management of pigs might be expected.

Group-housing in mating period

Increasing the duration of group-housing to cover the whole period after weaning until farrowing has some serious implications for design of the facilities and as always it is essential to ensure biological demands be met by:

- Controlling individual feed intake since this determines the litter size and body condition.

- Preventing aggression and bullying must as much as possible to reduce risk of abortion and loss of foetuses.

- Must include space for sows to escape in the group area and a kind of stall protecting the sow while eating.

- Solutions to keep the sow protected during the sensitive time around insemination might include individual pens allowing the sow to turn around or free access stalls. Theoretically, conventional stalls might also be used if the legislation allows sows to be crated for 3 days – however this solution should then be used in combination with a feeding system providing control of individual feed intake such as an ESF system.

- Designing the group pens according to the batch size and if possible, keeping gilts separately from sows.

Loose housed lactating sows

With respect to loose-housed sows in lactation a lot of trials have been done but there is still not complete consensus about the requirements for design based on research. In Germany the legislators have made several demands that are now directing design of facilities also in other countries such as Denmark and the Netherlands exporting millions of pigs to German finisher farms. On the other hand, German demands are changing continuously and right now the final demands are not clear.

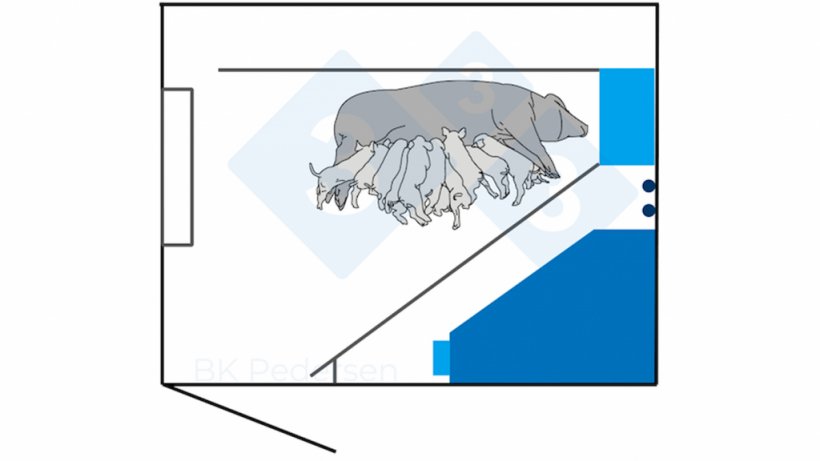

Previously, German requirements were as depicted in Figure 2. For now, German rules permit a farrowing crate that can be opened a few days after farrowing allowing the sow freedom to move. Since 80% of piglet mortality can be attributed to the first few days after farrowing and research shows that crating the sow around farrowing is reducing piglet mortality then hopefully this option will be allowed in future legislation.

It should be noted that pens for loose housing include 1 m high pen walls in the sow zone and a covered creep area with an area of roughly 1 m2. Of course, it is important that the sow cannot escape from the pen and worker protection is also important while considering pen design. EFSA suggests a minimum space requirement for the sows of 6.6 m2 which equates to 7.8 m2 pen space. It is still too early to conclude what future requirements will look like, however it is likely that the EU Commission will follow EFSA’s recommendation.

In Denmark square pens have been popular. See Figure 4. Rectangular pens similar to German ones are also installed.

New installations include fully slatted flooring and, in some cases a solid or drained part in the centre where defecation is less likely to occur. Many existing farrowing pens are 2.6-2.7 m long and 1.6-1.8 m wide. Unless the floor is fully slatted retrofitting might be difficult since the existing solid floor might be an obstacle for maintaining a good pen hygiene.

Another constraint is environmental requirement demanding reduction of methane and ammonia emission. Since the farrowing pen is larger so is the pit surface area as compared to a conventional pen. Therefore, Danish research is currently investigating how to include partly slatted flooring and different pit configurations to reduce emission of gasses. Since nest building materials are also required scraper systems are starting to be popular again as they both reduce emission rate significantly (up to 90%) and handle leftover straw.

Prolific genetics

Since the late 1990s the Danish pig producers genetics organisation started focusing on increasing litter size and other genetic companies have followed. The output of total and liveborn pigs have increased tremendously since then and today 18-20 liveborn is becoming the standard with the most prolific Danish breeds while others are still at 12-13. These developments must be considered in the farm strategy. If the output of a certain number of pigs is the target then consider the fact that if a prolific breed produces +10 PSY as compared to a less prolific breed then around 30% less sows are needed. In addition, sow feed requirement is comparably less.

If a certain number of sows is the target, then farrowing, weaner and finisher facilities must be designed according to the expected output. Considering the sow unit alone, design for high prolific breeds requires more farrowing crates – typically up to 20% more than is needed for the sow batch alone. Since sows generally might handle 14 piglets, surplus pigs must be placed at nurse sows that are moved from a farrowing section where they farrowed a week earlier. Moreover, space is needed for piglets weaned from nurse sows. So, in a pure sow herd without weaners it is necessary to include nursery sections for these piglets. Typically, three sections are required, and the design must include a comfortable warm environment since the piglets from nurse sows are usually very young and small. Handling high prolific genetics therefore also requires highly skilled managers – which must be considered as part of the overall farm strategy.