Anaerobic digestion consists of a set of microbiological processes in the absence of oxygen by which biodegradable organic matter is decomposed to produce biogas, a combustible gas consisting mainly CH4 (methane) and CO2, with a CH4 content between 55% and 75% by volume and small concentrations of other gases. This process can be carried out at room temperature (although with low yields), around 37 ºC (mesophilic digestion), or around 55 ºC (thermophilic digestion).

Apart from producing biogas for energy use, anaerobic digestion has other advantages

- Improves the fertilizing quality of the slurry by reducing particle size and viscosity, which favors infiltration into the agricultural soil, and reduces the content of readily biodegradable organic matter, which prevents episodes of soil anoxia.

- Reduces emissions of unpleasant odors, since part of the volatile organic compounds has been transformed into biogas.

- Inactivates insect eggs and larvae, weed seeds, and animal parasites

- Reduces greenhouse gas (GHG) emissions

- Promotes good efficiency of downstream nutrient recovery processes, due to mineralization during digestion

The above advantages alone may provide justification for adopting the process, but the economic justification usually depends on the farm's energy costs (if it provides energy savings) or energy prices (if it provides revenue from the sale of energy).

An important factor in the swine industry is the high concentration of hydrogen sulfide in the biogas (H2S), mostly from lysine sulfate or other feed additives in the form of sulfates. H2S is corrosive and reduces methane production, so it is necessary to substitute the amino acids in the diet that are in sulfate form with their anhydrous forms.

As with other systems, for any evaluation, the mass balance must be fulfilled and, in this case, it is important to measure the COD (chemical oxygen demand), which is conservative, that is, the COD of the slurry input is the sum of the COD of the products, biogas, and digestate. This property allows the COD balance of the digesters to describe the efficiency of CH4 production. Anaerobic biodegradability is defined as the fraction of COD of a substrate that is transformed into CH4 (0.35 m3 CH4/kg COD, under normal conditions of pressure and temperature - Nm3), volatile fatty acids, and microorganisms, under ideal laboratory conditions.

For pig slurry, biodegradabilities have been measured from 32% to 70%, or biogas yields (~65% CH4) from 5 Nm3/t to 18.1 Nm3/t, corresponding respectively to 0.062 Nm3 CH4/kg COD and 0.210 m3 CH4/kg COD. This large difference in yield is basically due to the storage time prior to digestion, with the lowest values being obtained when the CH4 has already been released to the atmosphere during storage, contributing to greenhouse gases (GHG). Therefore, it does not make sense to try to produce biogas from aged slurry.

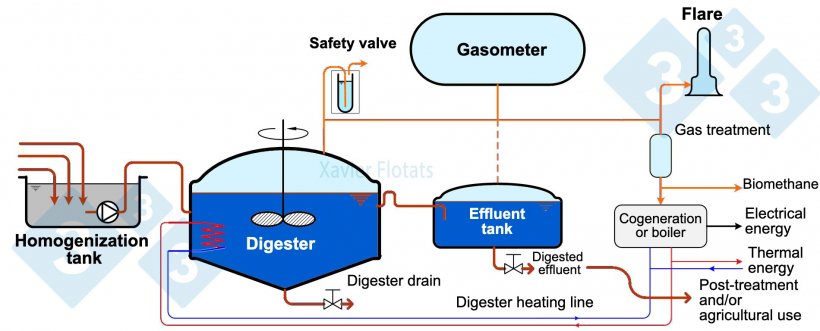

An installation consists of the systems illustrated in Figure 1, with a degree of complexity depending on the objectives to be achieved.

Figure 1. General diagram of an anaerobic digestion plant.

The core of the installation is the digester, of which there can be different designs. The simplest is the covered anaerobic lagoon (see Figure 2a), in which it is useful to add a pressurized biogas recirculation system at its base to avoid the accumulation of settled solids. This is a low investment system that allows the biogas that would be produced in the lagoon to be recovered and used for energy purposes on the farm. Performance improves if the temperature can be controlled, for example by using the residual heat from electricity production; otherwise, biogas production varies throughout the year depending on the ambient temperature.

The most common design is the CSTR (continuous stirring tank reactor) (see Figure 2b), in which a controlled temperature is maintained and an agitation system ensures homogeneity. The retention time can be around 20 days, but the need for co-digestion suggests that this time should be around 60 days.

Co-digestion consists of the joint anaerobic digestion of two or more co-substrates in order to achieve enough production of biogas and energy to make the investment profitable. Due to the low biogas productivity of pig slurry, it is recommended to mix it with waste from the food industry in order to achieve a minimum production of 50-60 m3 biogas/ton. This implies that the farmer must have administrative permits as a waste manager.

Biogas can be used for heating, by boiler, electrical and thermal production, by cogeneration, and as fuel for vehicles. Each of these uses requires an appropriate biogas treatment system, either to remove impurities or to enrich the CH4 content, in which case it can be injected into the natural gas grid.

What is the role of anaerobic digestion in a non-surplus situation?

What are the strategies based on biogas production in a surplus situation?