We were asked to design what the "ideal" station for cleaning animal transport trucks would be like. The procedure itself and biosecurity were taken into account.

The plant has the highest standards, but each company can determine which design would best fit its costs and needs.

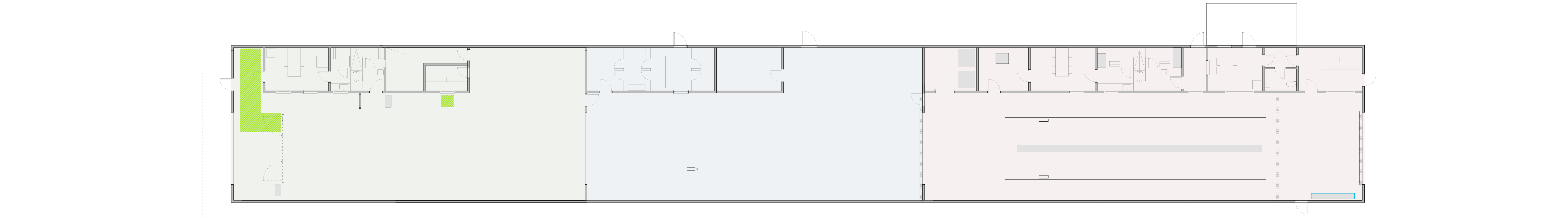

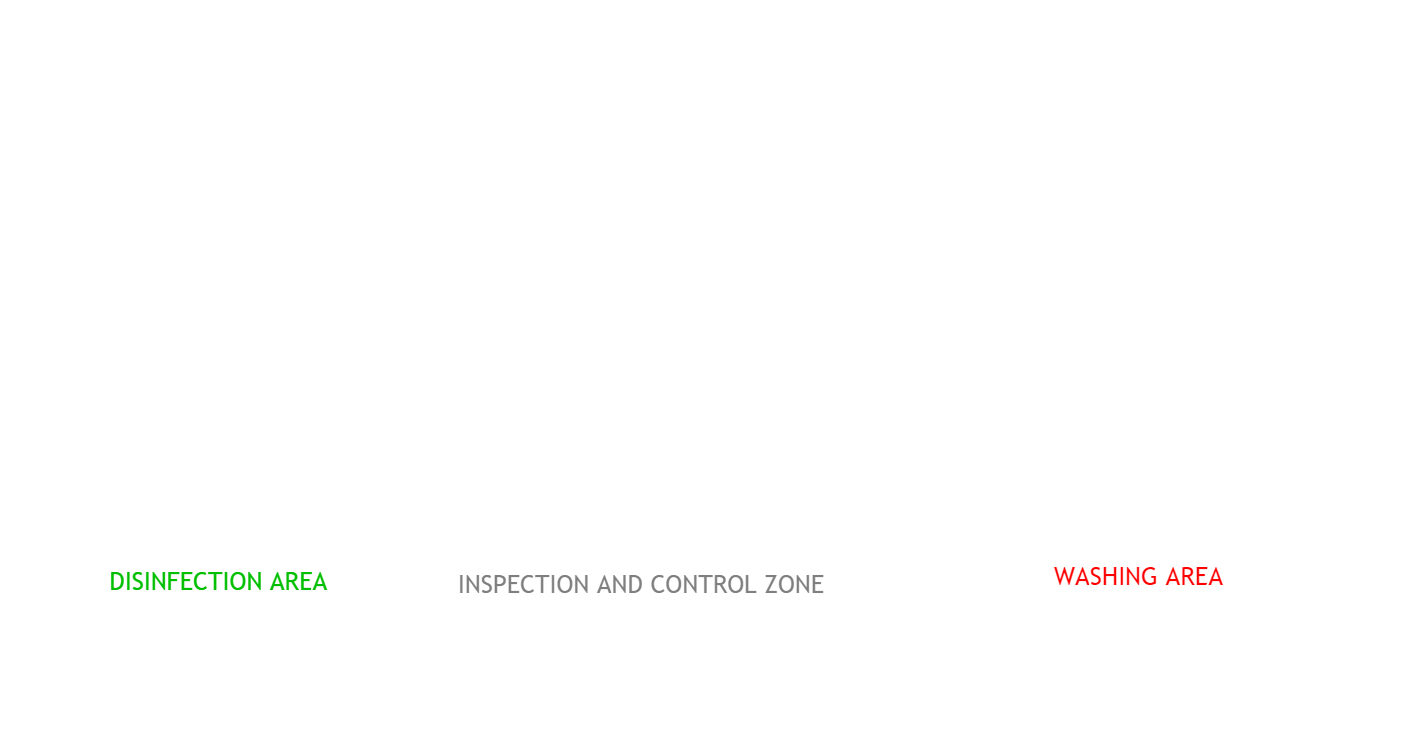

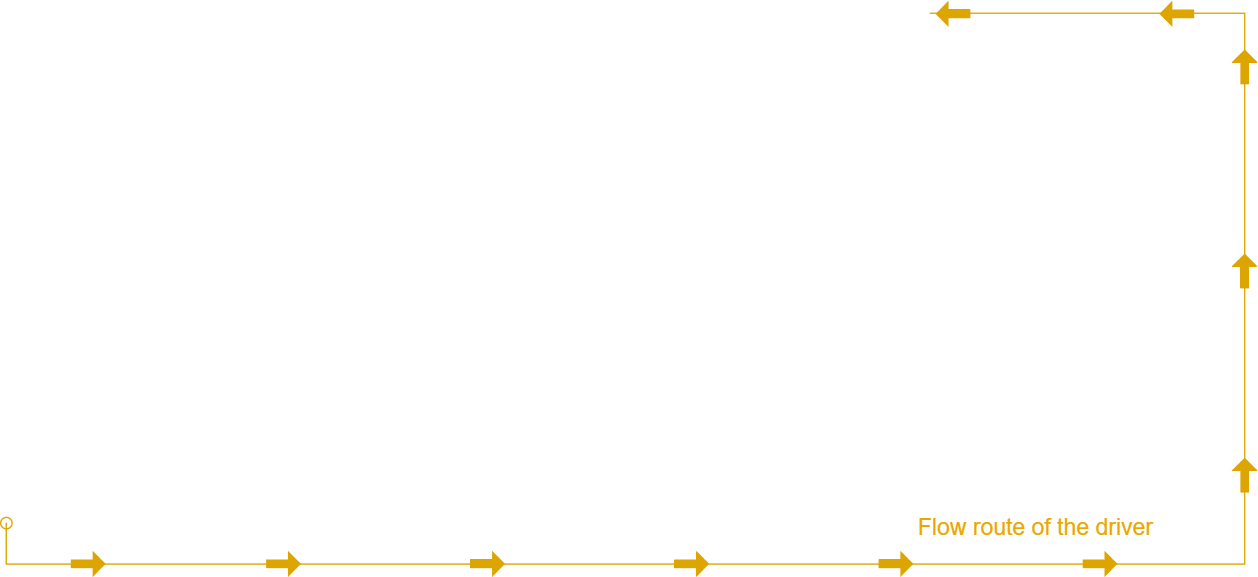

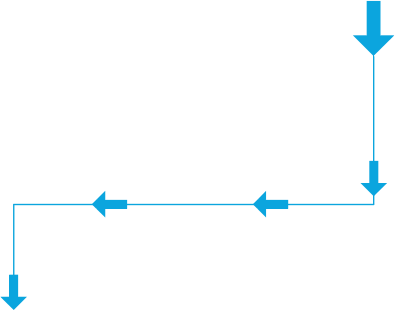

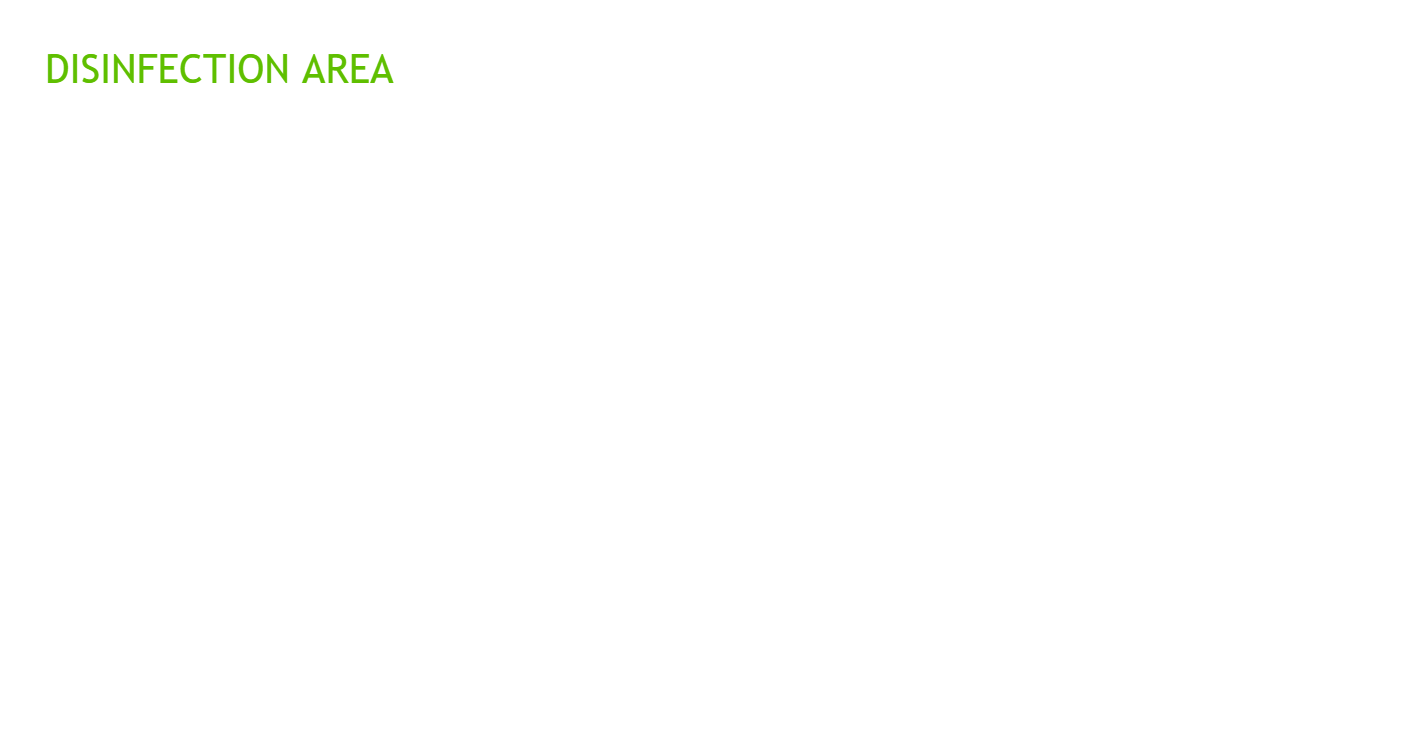

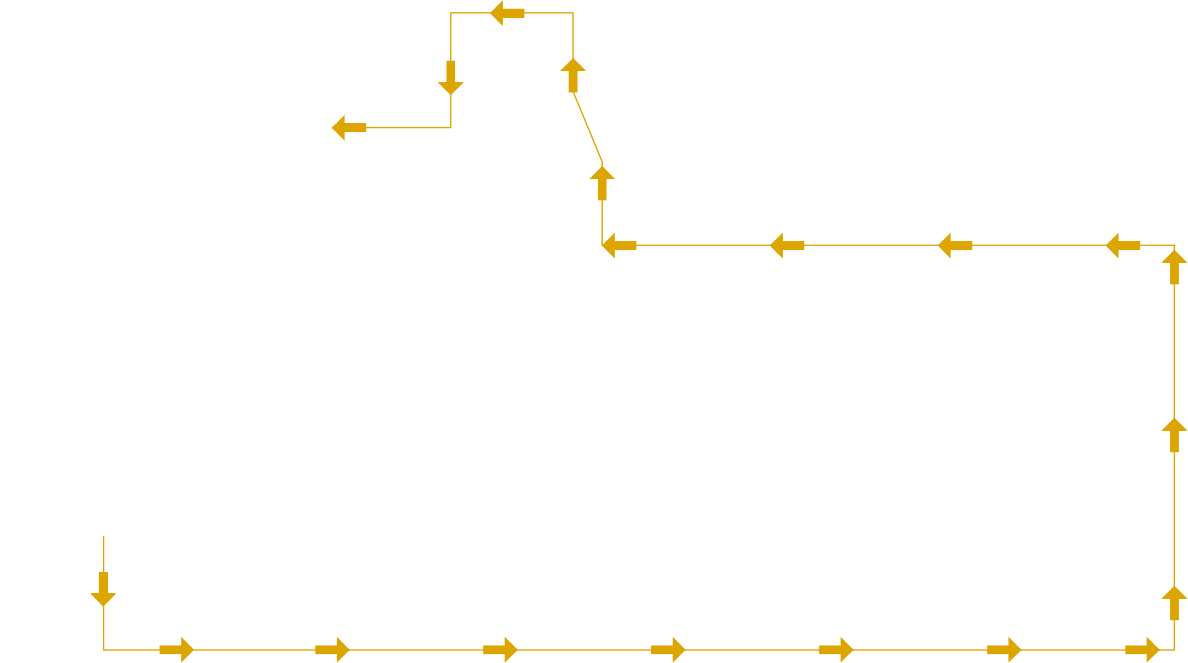

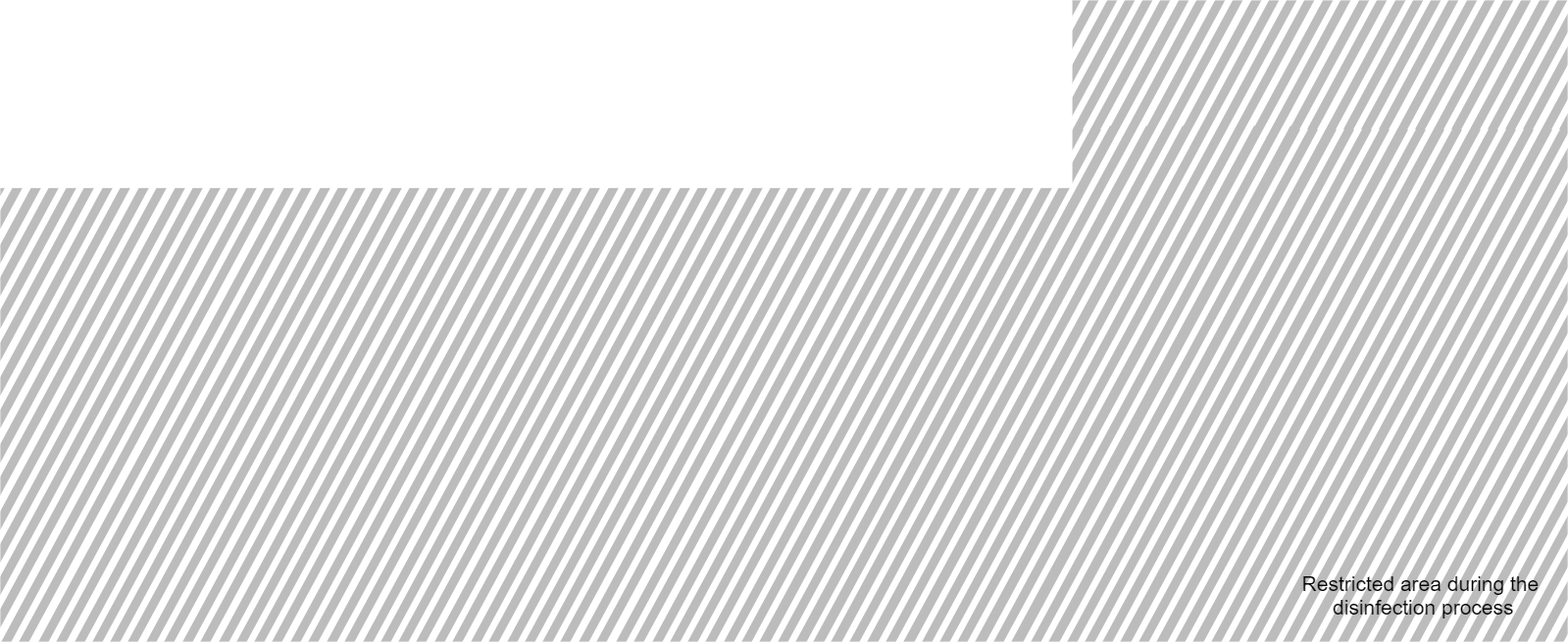

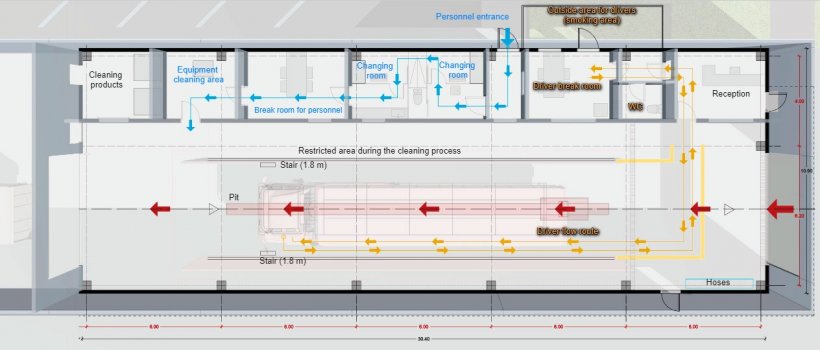

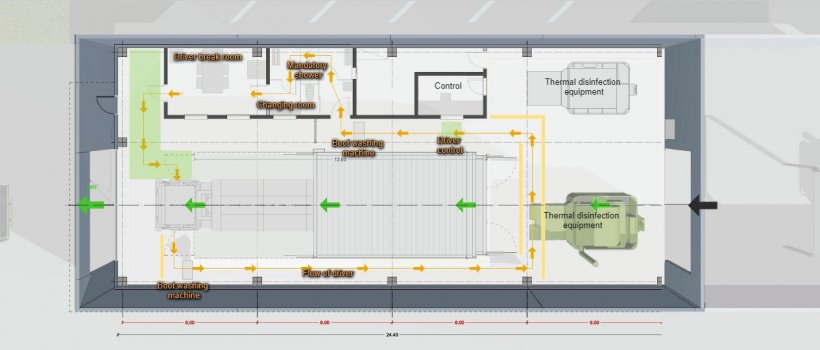

The plant has an independent entrance and exit, with a one-way forward flow, and has specialized personnel in each area to carry out the different procedures. The plant is divided into 3 areas: the washing area or dirty zone (in red), the area for checking the cleaning process (in grey) and the disinfection area or clean zone (in green)

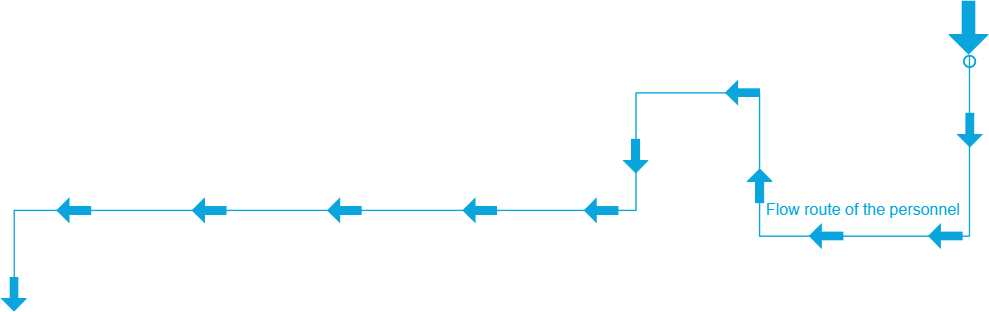

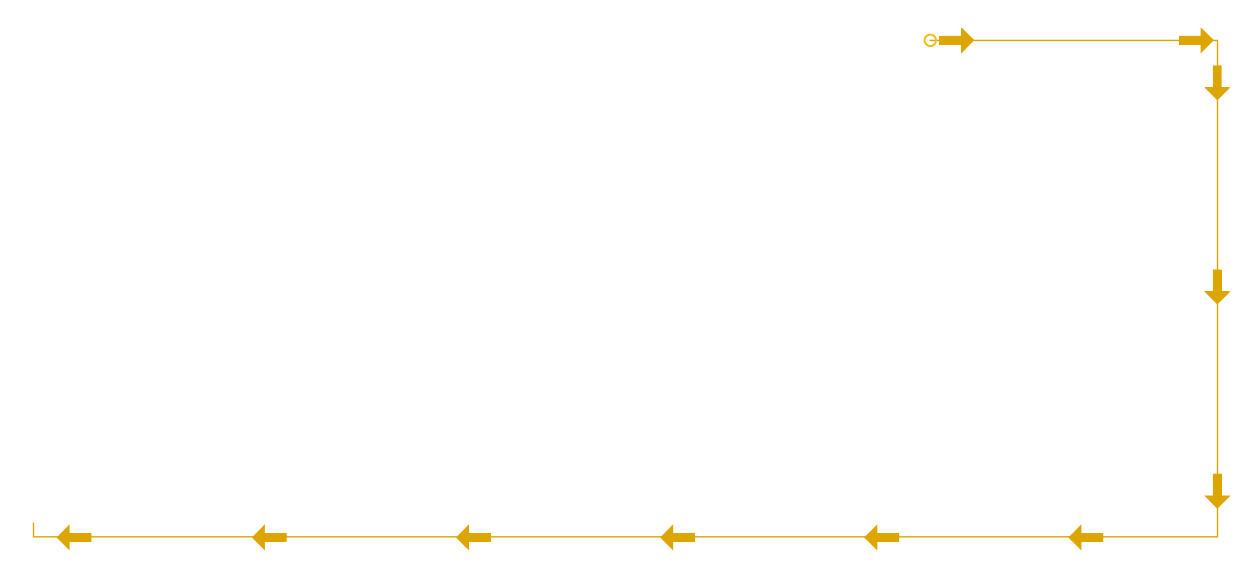

The flow of the truck, the flow of the plant personnel, and the flow of the driver who has to move the truck from one area to the next have all been taken into account. Due to the time required for the different tasks and the flow of the plant, the washing areas can be duplicated or triplicated with respect to the disinfection area(s).

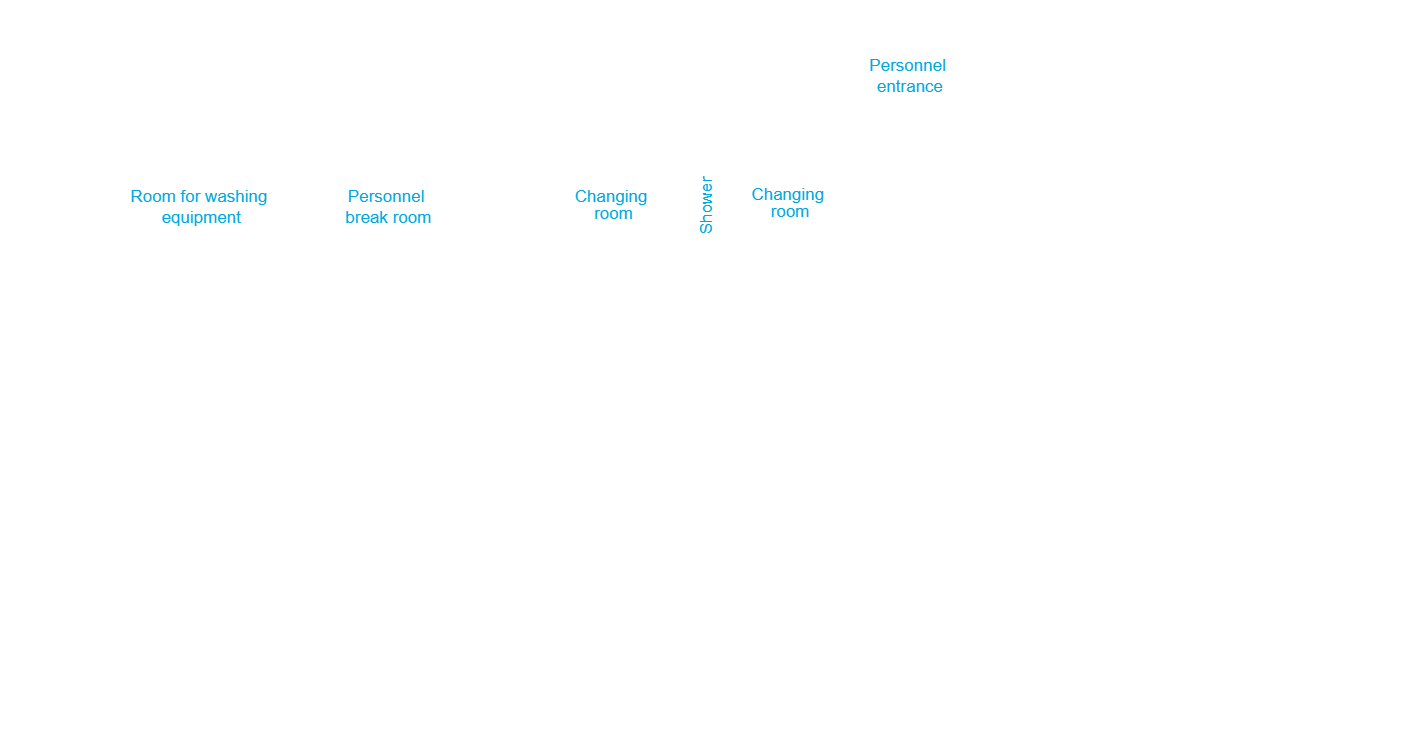

There are two changing rooms, one in the wash area and the other in the disinfection area with waiting areas and facilities so the station staff and drivers can shower and change its clothing.

The interior of the truck cabin is cleaned and disinfected in the disinfection area, except for the mats and removable elements which will be taken out at the dirty zone for cleaning and disinfection and will not re-enter the vehicle until it exits, once the whole process has been completed.

Critical points of the wash station

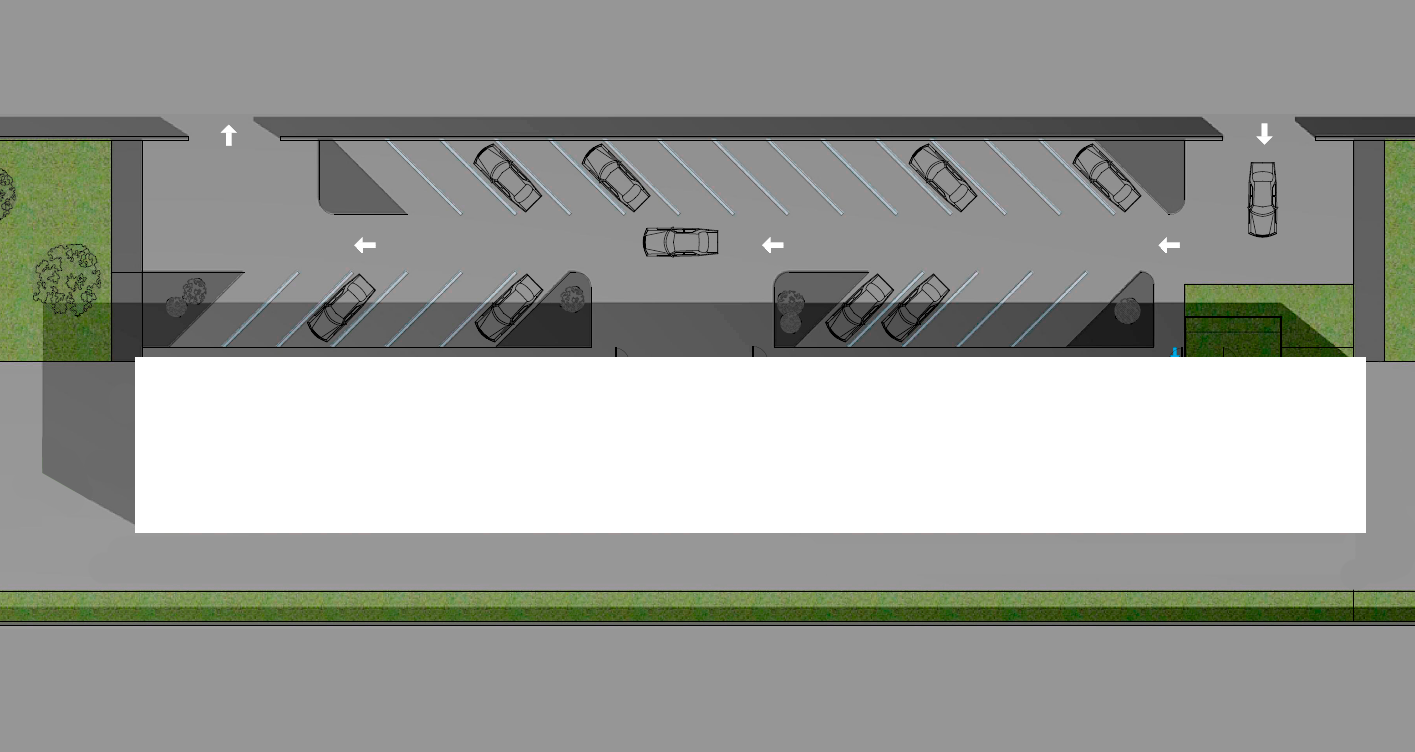

1. Waiting area for "dirty" trucks, at the entrance of the station.

2. Washing area or dirty zone:

- Before cleaning, a robot with hot water will take care of the truck's underbody (important if there is mud or snow) and remove the heaviest of the material from the underbody.

- Flow of drivers after leaving the vehicle parked in this area. They should go to reception and they have an area designated for resting or can exit to the outside.

- Flow of washing personnel: all personnel have access to the plant through a separate area where no intersection with lorry drivers occurs. They have changing rooms for a complete change of clothes and a shower to use upon exit. This changing room is connected to the break room and to the warehouse where the personal protective equipment (PPE) necessary for their work will be available (boots, waterproof suits, overalls, goggles, gloves and masks).

- Solids are removed either manually or with a low pressure, high flow hose.

- The mats and removable elements will be taken out to be cleaned and disinfected in an outside area, and then taken to the exit to be picked up.

- This area shall be equipped with a low-pressure but high-flow hose, detergent dispenser, and a high-pressure hose with hot water. There will also be a platform on the sides to allow for proper cleaning of the upper parts of the truck.

- In this area there will be a vacuum for cleaning the cab.

- It is important for the floor in this area to have the correct slope (2%-3%) to collect the water that was used for cleaning. It is also important for the area to have a good lighting system.

Washing area

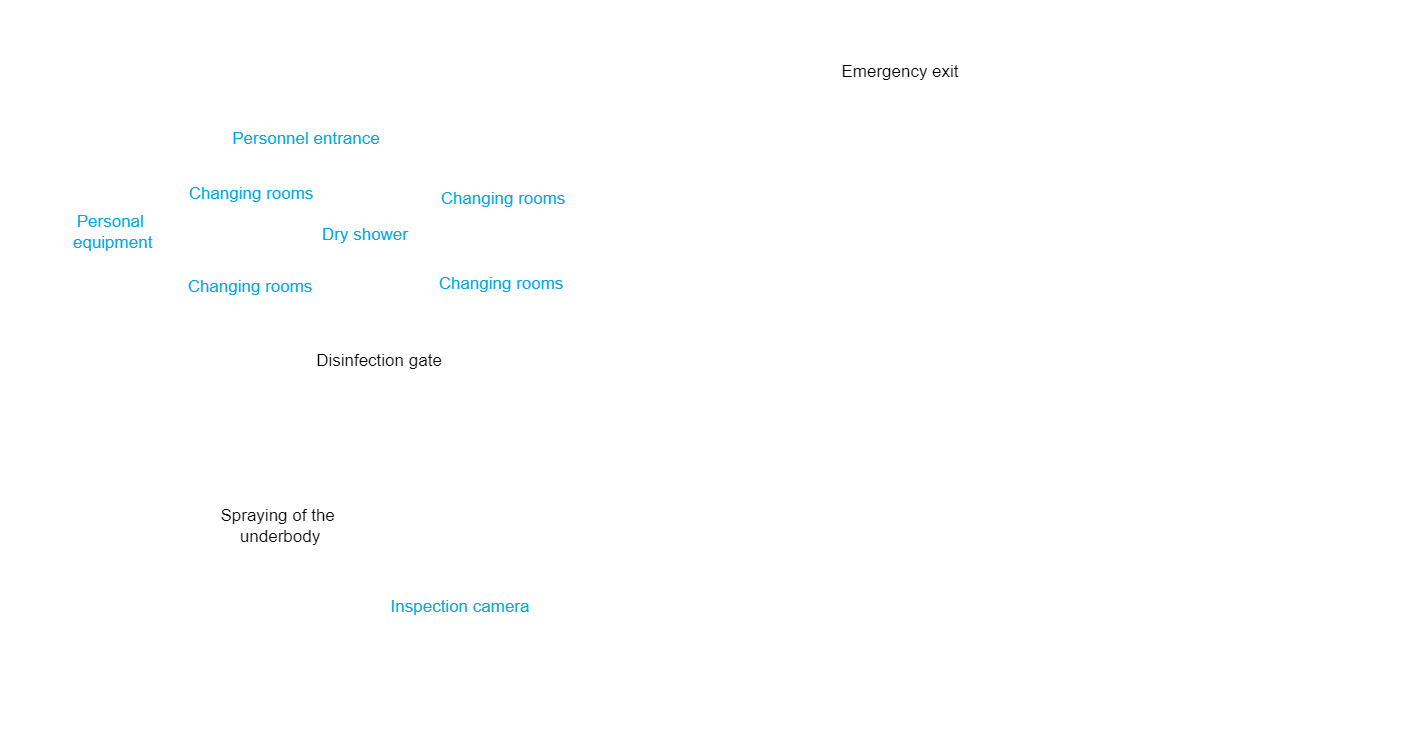

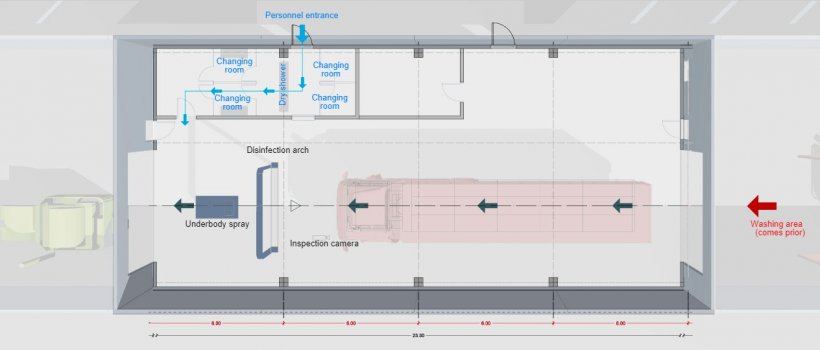

3. Intermediate area or grey zone:

- Once washing is finished, the driver will go through reception again and get into the cab to move the vehicle to the intermediate area. In this area, the driver will not leave the cabin.

- A visual or camera inspection of the state of the vehicle will be carried out before the truck is able to access the disinfection area or clean zone. The personnel in charge of the inspection will be the clean zone personnel, so as to not have the same operators who cleaned the truck.

- If given the OK from inspection, the truck will proceed through the disinfection gate and underbody disinfection, and will be allowed access into the clean area. If not approved, the truck must return to the cleaning area to make the necessary corrections.

- In this area there is the entrance and changing rooms for the personnel who work in the intermediate area and in the clean zone. Entrance will be by means of a "dry shower". A complete change of clothes and shoes will be required upon entrance and exit.

- The floor in this area will also have a 2-3% slope to allow the truck to drain.

Truck inspection area, after washing.

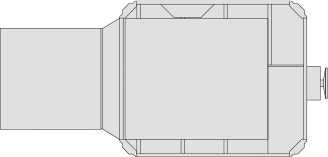

4. Disinfection area or clean zone:

- Upon arrival to the disinfection area, the driver will get out of the cab and go via a "dirty" route to his changing room where there will be a shower procedure and change of clothes and shoes (note that the driver will be entering a "clean" vehicle at the end). The dirty clothes can be bagged and sealed to take with (heat sealed), or, in the case of a company's private truck wash facility, be washed and disinfected. In addition, the driver will have access to a waiting area exclusively for drivers.

- The disinfection process can be done by heat, chemical disinfection, or both. In the case of this plant, a thermodisinfection system has been installed, but the machinery would only need to be modified in order to perform chemical disinfection.

- In this area, the cabin interior will also be disinfected.

- Once the disinfection process is complete, the driver will enter the cabin via a "clean" route, going up to the cabin through the passenger side door.

Truck disinfection area, in this case thermal disinfection.

5. Exit area:

- In this area there is space to park the clean trucks and at this time the removable elements (mats, pig boards, etc) that were taken out in the wash area and that have been washed and disinfected outside the truck wash, will be collected.

- In addition, the driver will receive a cleaning and disinfection certificate via e-mail.

- It is optional to have a sawdust storage area here.