Pigs per sow per year is certainly one of the most important economic factors to look for on a farm, as well as one of its main components, pig weaned per sow.

Over the course of my career, I had the opportunity to manage different sow farms where huge differences were seen in pig weaned per sow and preweaning mortality even though the genetic line, feed, and infrastructures were the same or extremely similar, proving that some producers are just better than others (graph 1).

Saving piglets is an art. The more you refine it, through observation, correction of mistakes, and new techniques, the closer you come to perfection. Some are true artists, others need more work.

Personally, piglet management was learned from experts around the world, but my knowledge also grew from farm employees. The best ones will implement the science we taught them, nonetheless, their day to day work and observations will bring it to a higher level. This paper will show four cases where farm people made differences on results.

Case 1: Farrowing induction

Many years ago, following the visit of specialists, I suggested to several farm managers to stop farrowing induction. The procedure was simple: let the sow farrow at her due date, no use of hormones except for major problems, and minimal interventions (sleeving). I call it "Natural farrowing", meaning to let the sow do her natural work and behavior. Few farm managers took the risk to try it, only the more adventurous and progressive ones did. The results were astonishing.

Here were the first comments from managers who tried it:

- Smooth farrowing without sleeving

- Sows are quicker to eat after farrowing

- Less antibiotic and anti-inflammatory used

- Better clean out of the placental membranes

- Less cannibalism

- Fewer piglets crushing

- Calmer sows

- Vigorous piglets drinking the colostrum faster after birth

- Better milking pattern of the sows

In short, the overall view of it was described as "less work and better results". With the help of technology, it didn’t take long before the word spread out through farms, and other managers started implementing this new method. We then realized that gestation length was much longer than before, that it varies over time and between different genetic crosses. This change in farrowing clearly showed sows were induced too early, that it disturbed their natural hormonal pattern and bring consequences with it.

At the same time, teeth clipping was completely stopped at birth as well as any other interventions. The idea behind it was to trigger the piglet’s survival instinct resulting in them drinking their colostrum.

Ten years later, "Natural farrowing" is still being used and results are better than ever with minimum stress to the sows and their piglets.

Case 2: Piglets cross-fostering and PRRS

In the early ‘90s, piglets cross-fostering was a very popular technique. Up to 75% of piglets were transferred between sows, classified by weight. Every piglet had to be the same size in every litter, mixing many litters together.

The venue of PCV2 and PRRS virus changed the face of swine production. Two great researchers inspired me in the research of reducing mortality and the impact of PRRS. Started from the main idea of Madec’s rules and McREBEL procedures, "cross-foster piglets only within the first 24 hours of life", I extended the rules to: leaving the maximum piglets to their mother, cross-foster only between 2 litters, piglets from parity 1 sow to another parity 1, and transfer the piglets only after colostrum have been ingested; no nurse sows, no fall-behind of lightweight piglets and runt or sick pigs being sacrificed. I called it the "minimal cross-fostering technique".

Again, conservative producers barely applied the technique at first, but the more progressive ones implemented it right away. The results were amazing. Suddenly, they realized that when you leave piglets to their mother, even in the situation of health challenges and differences in weight within the litter, the number of piglets weaned increased as well as their quality and size.

Another proof of "less work and better results", just by believing in the potential of the sow to save all her piglets whatever the number.

This technique is still widely used on farms and helps reducing many bacterial and viral diseases impact.

Case 3: Aptitude of people and preweaning mortality

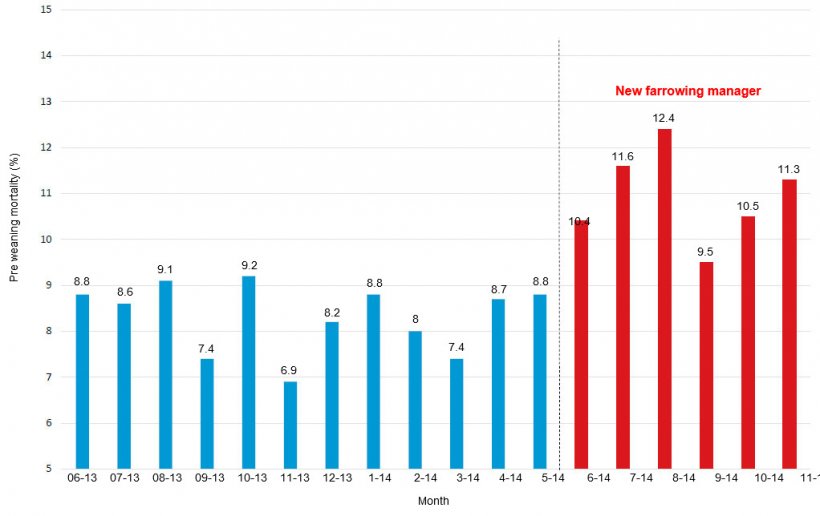

A few years ago, I was tasked to hire a new technical advisor. The job consisted of supervising seven sow farms, so the importance of choosing the right person was critical. From ten applications, one really caught my eyes, a young farm manager of a 1500 sows barn. Not especially the best interview, but what really struck me was her farm results. Year after year, she was always one of the managers with the lowest preweaning mortality. Her will for the job as well as her results really was what made me choose her. However, the interesting fact is that shortly after her departure, preweaning mortality from her farm increased by 2.5% (graph 2).

Seeing this, I was very curious to see what are qualities that differentiate the best farm managers from the rest. Certain characteristics are constantly coming back: their attention to detail, good observation skills, and judgment, calm, organized, well structured, preventive, do the most valuable work first, and finally, are quick to intervene in a problematic situation. As mentioned earlier, producers weaning a high number of quality piglets are like magicians, they get the most out of their primal resources.

Case 4: Weaning weight and weaning age

Weaning age and weaning weight vary very much over the years, going from 21 to 14-15 days with the event of early weaning and back to 18-19 days in the early 2000s.

In the mid-2000s, very good researches from Kansas State University and inspiration from the European movement for better welfare suggested that the best weaning age for better returns was 21 days and higher.

As a part of an integrated system in Canada, it was decided to remodel barns and bring back weaning age at 21 days minimum. New goals were set: 21 days or higher of weaning age and a minimum weight of 6.2 kg. Most producers reached these goals and some more ambitious went way over it.

However, one employee took pride in pushing the results to an extreme level. With a very similar number of farrowing crates per sow, she weaned week after week piglets of 25 days and 8 kg while the average of all other farms was about 21 days and 6.5 kg (graph 3). A weekly report of all weaning weights from all different farms was published so that every team could compare each other.

That employee was always at the top of the list. The more I valued her, the better her results were, producing high-quality piglets. She was the type of producer who understood sow lactation, nutrition, and piglet’s management so well that she really attained the gold standard.

Conclusion

Finally, throughout my career, I had many great examples where the results of a farm were really the product of one person pushing for excellence. Those people are much needed. Their will to always improve results and learning new skills bring others with them in their quest to be the best. The more you teach them, give them new information, push them, the more they answer to your demands. I always have had an enormous pleasure working with these people, and in return, I learned a lot from them and made my days much more stimulating.