A bit of history

In 1987, the founder of Yangxiang Co., Ltd., leading a group of enthusiast youngsters, launched a longan (a tropical fruit native to southern China) producing company, with which he obtained great results at an economic and social level.

In 1994, in accordance with the economy development trend, the company predicted that large-scale intensive farming would be one of the agricultural industries with great potential in China. It was then when Yangxiang launched its animal nutrition company and founded its first feedstuff company called “Guigang Yangxiang”.

Almost from the start, Yangxiang’s management team noticed that the business model in the animal nutrition industry was not comprehensive enough, and once the Guangxi Yangxiang Co Ltd was formally founded in 1998, it was decided to go a step further and combine feed, livestock (pigs) and meat processing to create a complete industrial chain model that has been characteristic of Yangxiang since then.

This development process made Yangxiang be considered in 2002 as the "Key national leading company for the agricultural industrialisation of China” and also to be considered, in 2005, one of the main 20 companies in the Chinese food sector.

In 2004, and as part of its definitive bet for a high-level pig production, the company made great investments in the building of high health status farms to produce GGP and GP genetic material and it also took the decision to introduce high-quality breeding stock from other countries. In this way, between 2005 and 2013, more than 2,000 SPF pigs from the USA and Denmark were introduced.

In 2014, Yangxiang completed what was, until then, one of the biggest and more advanced AI boar stud in the world: The Yajishan Pig Artificial Insemination Centre, co-built by China and Canada.

In 2016, the company, in its constant growth, invested large amounts in the building of farms, such as the Xinnong and Daliu farms in northeastern China. It was then when the building of the multi-storey farm on the Guifei mountain was started, making the number of sows of the company soar to 80,000.

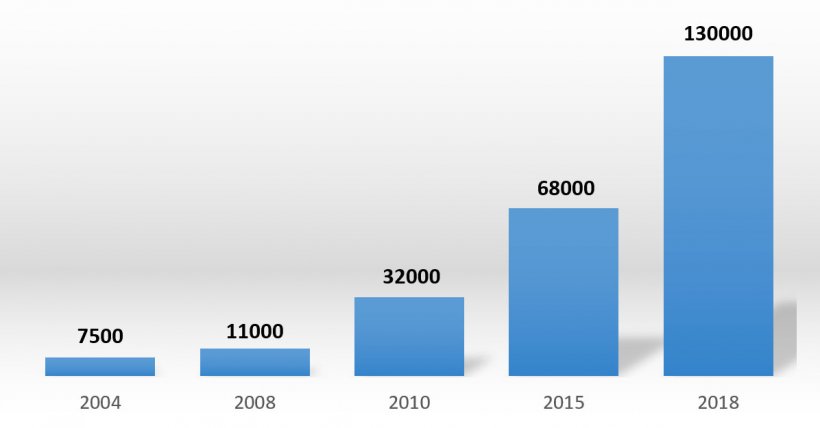

It is impressive to see the growth of Yangxiang on the graph, especially from the building of its multi-storey farms, going from 7,500 sows in 2004 to almost 130,000 currently.

Graph 1: Evolution of the number of sows of Yangxiang.

We met Yangxiang’s owner to understand a bit better the development of the project and what they have learned in the process:

333: How did this system come to your mind?

Yangxiang: We had a clear idea on the digitalisation of pig production and we found out that there was not an available system to analyse with data the 5 points that we think that are key in pig production: genetics, nutrition, biosecurity, the environment and production, so with this in mind, we decided to bet for the development of these systems in 2015.

Also, following the “technology changes the pig industry” principle, in 2018 Yangxiang and Yingzi Technology Co. Ltd signed a cooperation agreement for changing the way of understanding the pig sector in Asia through the digitalisation and the use of artificial intelligence and genetics.

333: It is a revolutionary system and we would like to know which have been the most important worries, difficulties or challenges that you have had to tackle when developing it:

Yangxiang:

- In a building like this, with the large number of animals that it houses, the erosion of the building due to the emissions worried us from the beginning.

- Fire is also something that worried us a lot, because a fire can ruin a very large production.

- Biosecurity is, without a doubt, one of the key pillars in the success of this system, and its complexity makes management not easy.

- Logistics also entail a great challenge, because understanding and organising a good flow of animals, people, supplies, etc. becomes a difficult task.

- Ventilation is, undoubtedly, the main challenge of a production system like this due to several reasons:

- Be able to assemble a filtered air system with guarantees.

- Assemble an air conditioning system that allows us to reach acceptable temperatures for most of the year.

- Distribute the air perfectly through a central corridor system.

- Design the perfect air extraction system through a negative pressure that allows us to take the residual air from each floor to the upper part of the building.

- Last but not least, we have the design of an air cleaning system before the air exits the system. In fact, since 2017.

- We have not exceeded 27ºC inside the farm whilst the temperature outside was 37-38ºC, so we think that the system is working well.

6. Lastly, the obtaining of the permits to build a facility like this, it has been a great challenge, because nobody has done a similar project before. I am convinced that, after the initial experience, we will see the advantages of these kind of systems and the legal processes will be easier.

333: After the experience gained, will Yangxiang still bet for a production model like this?

Yangxiang: Of course. We understand that this must be the model and what we are doing now is to perfect it.

333: Finally, what improvements are you considering for the future projects?

Yangxiang:The next units that we are building have 10 and 12 floors, because we have seen that this building model is more efficient.

Currently, Yangxiang and the multi-storey intelligent farms are at the forefront in the pig industry, and that has made the pig sector lay eyes on it, both at a national and an international level. In the future, Yangxiang will explore a newer and more efficient pig production model through intelligent systems and Big Data, and will constantly look for opportunities to reduce costs, helping the farmers to reach “an efficient pig production and a happy life”.