The once strenuous task of weaning, vaccinating, and, sometimes, sorting piglets by size or sex has been made easier for both farm staff and piglets with a new invention. Two employees of HyLife sow farms in La Broquerie, Manitoba, Robert Lafrenière and Barak Doell, have created what they call the “Hylife weaning ramp.” Typically, in the weaning process workers must repeatedly pick up piglets from floor level to bring them to another worker who administers the vaccine. This puts strain on the workers’ arms and back. The use of a weaning ramp solves this issue while improving animal welfare. While there are different thoughts and approaches to vaccinating at the time of weaning due to added stress, this is a common industry practice.

Here’s how the ramp works

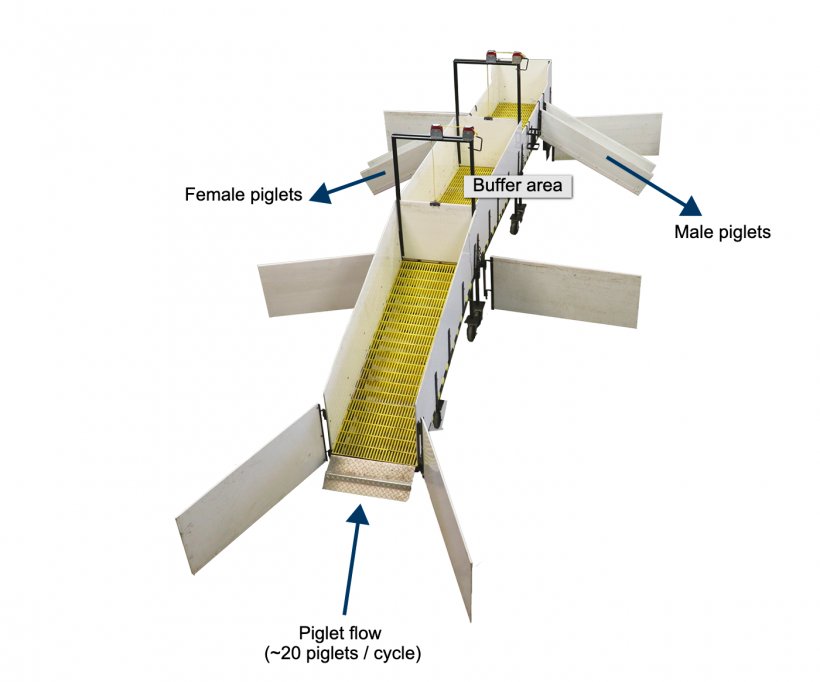

In the alleyway of the farrowing room, piglets move towards the ramp and continue up in groups. Once inside, a gate is lowered via a pulley system. From here at waist level, the farm staff can more ergonomically pick up the piglets and vaccinate them. The piglets can then be sorted, in the case of Figure 2, by sex, by placing them on the respective slide off either side of the station, bringing them back down to ground level safely and gradually.

The ramp received the F. X. Aherne Prize for Innovative Pork Production at the 2023 Banff Pork Seminar (BPS) and endorsement from renowned animal behaviorist Dr. Temple Grandin.“I was amazed how well those little pigs used the ramp; that's the kind of stuff that makes handling easier… It gets rid of the back-breaking work."

Editorial staff 333