Tip description

The entry & exit points for the movement of people, pigs, and supplies into and out of swine production facilities are often located closely to each other. This increases the potential for cross contamination and the tracking of unwanted disease into your herd. Studying the pattern of traffic flows for your production site is important when designing your “bioexclusion” game plan.

Applying the tip

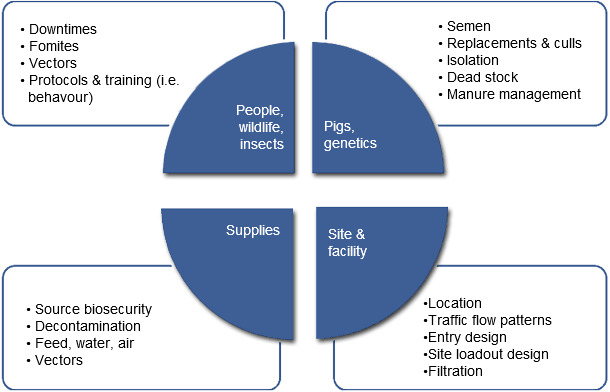

Properly managing of the movement of pigs, people, and supplies can decrease the risk of 'tracking' unwanted disease into your herd. Figure 1 is a common list of factors that are reviewed when a biosecurity program is being created or audited.

The site layout design and location of entry and exit points will directly affect the facility’s traffic patterns. If these patterns promote the crossover and contamination of incoming traffic with materials that contain infectious organisms, the likelihood for the ‘tracking’ of disease into the herd rises. The goal should be to minimize or eliminate these unwanted points of contact.

An approach that could be used to understand these traffic patterns and where the risks of cross-contamination are the greatest could include the following steps:

- Create a map of your site,

- Identify the exact locations where the pigs, people, and supplies enter and exit,

- Identify each individual type of movement,

- List the frequency of each movement and when it occurs,

- Note important biosecurity related comments, and

- Create an prioritized action plan.

The following example shows a scenario where a farm was using the same trailer to transfer cull sows every two weeks on Wednesdays to a commercial transport company and replacement breeding gilts every month from their own isolation unit on Thursdays. From the same loading chute, they were hauling dead stock out with the farm tractor directly to the dead stock bin. Possible corrective actions to manage the risk of cross contamination are listed in the table.

| What? | Entry point | Frequency | When | Comment/Concerns | Actions | Priority |

| Gilts in | Load out/in | Once per month | Thurs | Transferred from isolation unit | Change trailer, chute, date | High |

| Cull sows out | Load out/in | Every 2 weeks | Wed | Transferred to a commercial hauler | As above | High |

| Dead stock out | Load out/in | As needed | As needed | Picked up with the front end loader and hauled to a dead stock bin for pick up. | Build cement pad at a separate door and move exit point | High |