Coronavirus (SARS-CoV2) has proven extremely challenging for the U.S. meatpacking industry. Meatpacking plants employ hundreds to thousands of employees at each facility who, because of the nature of the industry, often work in close contact. Additionally, in many packing plants, a multitude of languages are spoken, representing a diverse set of cultures. Taken in combination, these factors have presented unique challenges in limiting the spread of SARS-CoV2 within the packing plant workforce.

U.S. meatpackers have been extremely aggressive in identifying and adopting best practices to limit the transmission of SARS-CoV2 within their workforces. At the beginning of the outbreak in the United States, little was known about the routes of transmission and the best practices to prevent spread. This led to increased rates of transmission in individual packing plants as the virus was introduced into those communities. As scientists and doctors identified potential routes of transmission, packing plants utilized their extensive knowledge of infection control – which in the past had been primarily directed at food safety - to modify the environments and working conditions to prevent the spread of disease. While these strategies and changes have come at a tremendous financial cost, their results are promising.

When these strategies are implemented effectively, and before significant rates of infection are detected within the local community, infection rates within packing plant workforces have often been lower than within the community at large.

This data strongly suggests that the new plant measures have been highly effective.

The foundation of these control practices has been open communication with the workforce. This means that packers have identified a clear plan for testing, contact tracing, and isolation based upon guidelines published by the Centers for Disease Control and Prevention. The packing plants have made this information available to their employees, in their languages, and in their communities. This communication, plus effective collaborative work with local public health departments, has led to the workforce understanding the infection risks and what actions everyone needs to take to stay safe. Anecdotally, it appears that this communication effort to build workforce trust and confidence that their workplace is safe has been a critical step in not only maintaining adequate numbers of workers but also ensuring compliance with the surveillance and mitigation strategies.

Based on the CDC's guidelines, almost all packing plants have implemented daily temperature checks for all workers and visitors entering the plant. Temperature screening occurs before entry to the facility, and temperatures above 38° C - based upon U.S. CDC guidelines - result in individuals being denied entry to the facility. Combined with deep collaborations with medical doctors and local public health departments to provide adequate testing, this has been a cornerstone of control processes at packing plants. The goal of this strategy is to eliminate the entry of infected individuals, which would create the potential for viral transmission within the workplace.

Screening of employees for infection has been widely used and routinely successful. In some plants, the entire workforce has been screened. Much of this testing has been done by private laboratories with very rapid turnaround, allowing notification of employees, rapid contract tracing, and subsequent follow-up testing to ensure that the infection is not spreading. Anecdotally, it appears that mass testing with contact tracing and subsequent quarantine, when coupled with the other mitigation strategies, has essentially stopped transmission within the workplace.

Within individual plants, significant efforts have been made to stop both aerosol and fomite (physical object) based transmission. It has become the routine practice that all employees wear a mask while in the facility unless they are eating. These practices were adopted more rapidly within packing plants than by society at large in the United States. Again anecdotally, it appears that mask-wearing within the packing plants - when coupled with testing - has been very successful in eliminating within-workplace transmission. In addition, some plants have implemented face shield requirements to ensure that small droplets are not contacting the nose and eyes, although this is less universal than mask-wearing and its effectiveness is not yet known from scientific research.

Packing plants have been aggressive at increasing internal hygiene. In many cases, numerous employees have been tasked with cleaning and disinfection of all common areas. Per U.S. law, production areas of packing plants are cleaned and disinfected daily in a very robust manner. This was historically designed for food safety, but also eliminates SARS-CoV2 from the work floor and contact areas. Enhanced cleaning in common areas, including lunchrooms, break rooms, restrooms, hallways, and time clocks, of a minimum of three times per shift, has been adopted in many packing plants. Cleaning is being done with a variety of disinfection and cleaning agents which are food safe and have been documented to kill SARS-CoV2. The actual chemistry is not nearly as important as the frequency and completeness of the cleaning - wiping down all common surface areas to remove any dirt and debris, followed by disinfection of those surfaces.

Numerous plants have been aggressive in eliminating contact points to minimize the frequency of worker interaction. This includes:

- Placing dividers on all lunchroom tables. Masks cannot be worn while eating, and these dividers ensure that workers can only sit by themselves. These dividers are typically made of plexiglass and extend over three feet high above the tabletop to prevent airborne transmission.

- Plants have developed systems to ensure cleaning between uses, often with a red/green card - after an employee uses a station, they turn the card over to the red side, signaling that it needs to be decontaminated before its next use. Aggressive use of these dividers has prevented workers from facing each other at lunch tables, minimizing aerosol transmission across the table.

- Spreading out time clocks and other stations where employees are required to report has been common to minimize congregation.

- Tactics such as propping doors open to eliminate the need to touch door surfaces, as well as reconfiguring restrooms so that all facilities are non-touch (photocell operated), have helped minimize disease transmission.

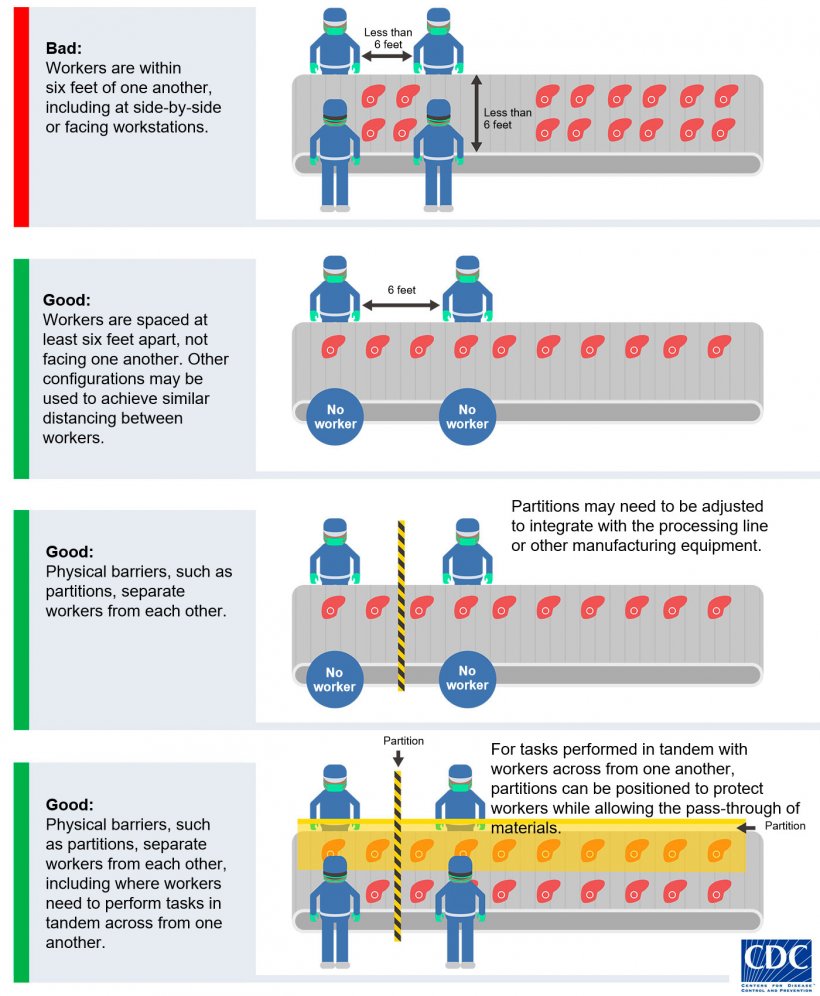

- On the packing floor, partitions between employees on the line have also been installed to isolate workers that are not able to stand six feet apart.

Based on the currently available research about the routes of pathogen transmission, it is not fully understood which of these practices are most important. Recent research from the human literature would strongly suggest that prolonged contact in small droplet aerosol transmission in close quarters is probably the most common way for SARS-CoV2 transmission to occur. Less likely transmission may be due to fomites that are contaminated with respiratory droplets. Until more is known about transmission, it is unlikely that any of the existing mitigation strategies can be removed.

The public media portrayal of U.S. packing plants has been that there are poor working conditions and high rates of transmission. Certainly, some of the initial outbreaks within U.S. packing plants were severe, and it now appears that packing plants were fortunate not to have infections within their communities early in the U.S. outbreak. Since the SARS-CoV2 outbreak began, U.S. packing plants have developed a set of reasonable mitigation standards to protect their workforce and allow continued operation of their facilities, minimizing bottlenecks within the meat supply chain. On a positive note, in the last three weeks, the United States packing industry has returned to pre-pandemic harvest levels. These numbers suggest that packing plants are back to nearly full staff and capacity. The low reported new cases of infection in the plants, and the promising harvest levels together indicates that current mitigation strategies, and more importantly employee confidence, are robust enough to return to work.