It is known that feed cost represents more than 60% of the total costs in pig production. Among the alternatives currently available to improve the efficiency of feed use are, on the one hand, a wide variety of food additives and, on the other hand, the presentation of feed in liquid form that, as well as the use of by-products from the agri-food industry, has been shown to reduce feed costs.

The use of by-products has increased significantly in recent decades, and it will continue to increase throughout Europe because by-products are a source of nutrients at a much lower cost than conventional raw materials. However, the high demand for by-products is likely to lead to an increase in their cost, which could diminish the competitiveness they currently offer, with respect to raw materials.

Knowing the potential full value of a given by-product for animal feed is of great interest. Prior to using a particular by-product, it is desirable to consider, in addition to its potential nutritional value, both its logistical constraints —such as supply, seasonality of supply, variability in nutrient contents, water content, palatability, management, cost/benefit ratio— and the precautions associated with its use (Brooks et al., 2001, Braun and de Lange, 2004, Shurson, 2008)

By-products currently available for pigs

Currently available by-products include products originated from industries such as dairy, bakery, sweets, alcohol, potato, soybeans, nuts or candy ... (Braun and de Lange 2004, Llanes and Gozzini, 2013).

Generally, when there is not too much information on by-products and only their estimated nutritional value from dry matter is available, it is assumed that the maximum level of inclusion in order not to compromise productive performance, should not exceed 15% of the diet in fattening pigs (de Lange et al., 2006). However, animal trials are essential for evaluating their digestibility, palatability, animal performance, and potential risks associated with their use, as well as determining their maximum inclusion levels, which are derived from the results obtained for those factors and will provide, as a final result, the potential value of the by-product (Boucqué and Fiems, 1988).

By-products evaluation

After evaluating their proximal chemical composition at laboratory level, two different in-vivo digestibility experiments were performed to investigate the nutritional value of eight potential by-products for liquid feeding (Table 1). In the first experiment, four conventional by-products (liquid bakery by-products, brewers grains, hominy feed and high-moisture corn) were studied using the difference method, with a 50% inclusion of the by-products (based on dry matter) to the basal diet (2.7:1 ratio). A total of 30 fattening pigs weighing 86 kg were individually assigned to four by-products diet groups plus one control diet group, without any by-products (n = 6). The second experiment was divided into four trials for the study of four non-conventional by-products (mayonnaise, almond flour, cocoa flour and kiwifruit). Unconventional by-products were studied using the regression method, increasing inclusion levels (2, 4, 7 and 10% for mayonnaise, almond flour and cocoa flour, and 4, 8, 12 and 16% for kiwifruit) to the liquid diet (2.7:1 ratio ) with 16 fattening pigs of 40 kg LW individually assigned to every trial (n = 4).

Table 1. Proximal chemical composition of by-products used in in-vivo experiments (based on dry matter).

| % | Liquid bakery by-products | Brewers grains | Hominy Feed | High moisture corn | Mayon. | Almond Meal | Cocoa Meal | Kiwifruit |

| DM | 33.8 ± 0.02 |

22.5 ± 0.01 |

84.8 ± 0.04 |

68.0 ± 0.00 |

53.4 ± 0.06 |

94.5 ± 0.06 |

82.2 ± 0.04 |

6.1 ± 0.01 |

| OM | 98.5 ± 0.01 |

95.7 ± 0.02 |

97.6 ± 0.00 |

97.8 ± 0.00 |

97.8 ± 0.02 |

98.0 ± 0.04 |

95.5 ± 0.01 |

89.9 ± 0.19 |

| GE (Kcal/kg) | 4.544 ± 3.7 |

5.53 ± 44.1 |

4.604 ± 35.0 |

4.380 ± 13.4 |

8.737 ± 91.7 |

7.462 ± 0,75 |

4.851 ± 31.4 |

4.939 ± 66.8 |

| CP | 8.0 ± 0.00 |

27.0 ± 0.03 |

9.3 ± 0.02 |

8.7 ± 0.05 |

1.3 ± 0.89 |

16,9 ± 0,30 |

8.9 ± 0.00 |

13.8 ± 0.00 |

| EE | 6.6 ± 0.05 |

8.5 ± 0.04 |

3.3 ± 0.09 |

4.2 ± 0.02 |

83.1 ± 10.99 |

57.4 ± 0.61 |

13.6 ± 0.13 |

4.4 ± 0.21 |

| CF | 0.5 ± 0.02 |

14.5 ± 0.26 |

7.2 ± 0.10 |

2.0 ± 0.06 |

0.00 | 2.9 ± 0.25 |

6.9 ± 0.41 |

16.0 ± 0.15 |

| NDF | 2.2 ± 1.3 |

59.6±5.61 | 41.8±0.85 | 8.0±0.08 | 0.00 |

2.6 ± |

13.4 ± 0.21 | 19.9 ± 0.24 |

| ADF | 0.4 ± 0,09 |

19.5 ± 0.68 |

8.6 ± 0.26 |

2.3 ± 0.02 |

0.00 | 2.6 ± 0.22 |

13.4 ± 0.21 |

19.9 ± 0.24 |

| Lignin | 0.1 ± 0.04 |

3.6 ± 0.83 |

0.9 ± 0.07 |

0.1 ± 0.04 |

0.00 | 0.7 ± 0.08 |

6.0 ± 0.10 |

6.5 ± 0.20 |

EB, Gross energy; EE, Ether extract ; ADF, Acid Detergent Fibre; CF, Crude fibre; NDF, Neutral Detergent Fibre; OM, Organic matter; DM, Dry Matter; CP, Crude protein.

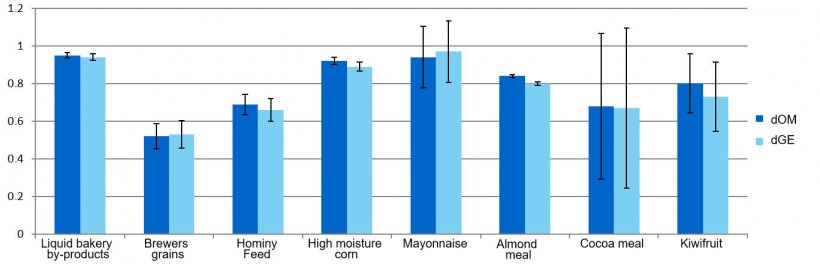

The results of dry matter digestibility (dDM), organic matter digestibility (dOM) and gross energy digestibility (dGE) were higher than 80% for high moisture corn, liquid bakery by-products, mayonnaise and meal almond, but did not reach 80% in the brewers grains, hominy feed, cocoa meal and kiwifruit (Figure 1).

Graph 1. Representation of organic matter (dOM) and energy (dGE) coefficients of by-products.

It was concluded that liquid bakery by-products, high moisture corn, mayonnaise, and almond meal have a high potential to be used in liquid diets for pigs. However, brewers grains, hominy feed, cocoa meal and kiwifruit, if used, should be included at low levels because of their high fibre content (Sol et al., 2016).