Introduction

The purpose of a ventilation system is to remove excessive moisture and heat produced by animals in order to maintain an indoor climate within certain limits. Animals also produce carbon dioxide generated from metabolism. However, when the ventilation system is designed for controlling temperature and humidity carbon dioxide concentration is normally kept below the recommended maximum level of 3000 ppm. Yet, there are exceptions such as the first week after introduction of newly weaned pigs to a hot nursery. Under these conditions CO2 concentration might be much higher, which means that a higher ventilation rate is required.

Designing the ventilation system

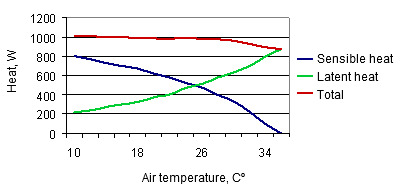

The ventilation requirement varies according to season, category of pig and feed intake. Moreover, an animal’s total heat loss at any given time is partitioned between sensible and latent heat fluxes. Sensible heat loss is determined by the temperature difference between the skin and the air temperature and heat is lost via convection, conduction and radiation. When air temperature and skin temperature are similar all heat loss is accounted for by evaporation of water from the lungs (hyperventilation) and from the skin. Thus, when environmental temperature rises, latent heat flow accounts for a progressively larger proportion of total heat loss (Figure 1).

Figure 1. Partition of total heat loss from pigs via latent and sensible avenues.

During cold conditions sensible heat produced by the animals is warming up the building, and is therefore part of the heat balance of the building. It might be necessary to add heat from an artificial source to maintain the temperature of the building. Heat (Q) is lost through the structure of the building and via ventilation. The heat balance of the building can then be defined as:

The building and ventilation heat loss is depending on the difference between outside and inside temperature. The greater the temperature differences the higher the heat loss. In Spain there are several climatic zones and climatic tables might be used for defining the design temperature that is used for calculating heat loss and ventilation rate. Normally, the 2.5 and 97.5 percent values for the temperatures are used as reference point meaning that in a normal winter or summer, respectively, temperatures are exceeded 97.5 or 2.5 percent of the time.

The winter design temperature is used as design criteria for building insulation and for calculation of building and ventilation heat loss during winter. If the sum of the two heat losses exceeds animal heat production – artificial heat must be added. The winter ventilation rate is designed for maintaining relative humidity below 70 percent. At this rate air quality is acceptable, heat loss is minimized while building quality is maintained.

Animal heat production

Animal heat production may be expressed in Watts (W) or heat producing units per animal. One heat producing unit is equal to the number of animals required to produce 1000 W at 20 C (Table 1.)

Table 1. Heat producing units per animal and recommended temperature.

| Category | Weight, kg/animal | Heat producing units/animal | Recommended temperature, C |

| Newborn pig | 1 | - | 30-34 |

| Piglet | 5 | 0.04 | 26-32 |

| Weaned pig | 15 | 0.08 | 20-22 |

| Weaned pig | 25 | 0.11 | 15-20 |

| Finishing pig | 50 | 0.17 | 15-20 |

| Finishing pig | 70 | 0.21 | 15-20 |

| Finishing pig | 90 | 0.24 | 15-20 |

| Gestation sow | 175 | 0.30 | 15-20 |

| Lactating sow | 175 | 0.44 | 15-18 |

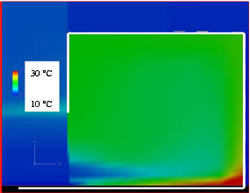

Figure 2. A cover above the creep area is raising temperature 6-8 C above the room temperature.

Animal heat production and temperature requirement vary with stage of reproduction, feed intake and environmental condition. Thus, finishing pigs and lactating sow are producing relatively more heat than any other category of pig. A covered creep area in a farrowing pen conserves heat and the effect is that the temperature of the creep area is 6-8 C higher than the room temperature. This means that it is possible to maintain a lower temperature in the room in order to accommodate the sow as compared to a farrowing room with open heat pads.

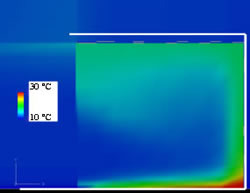

Figure 3. Effect of cover design on temperature (adopted from Danish Institute of Agricultural Science).

|

With lip |

Without lip |

Artificial heat

Artificial heat might be supplied via hot water pipes, such as delta-pipes and pipes with ribs placed below the air inlet, which means that the cold incoming air will be heated. This will prevent cold air currents in the animal zone. Heat is transferred to the air via radiation and convection. Delta pipes might be made of steel or aluminium. However, steel pipes are more efficient in providing heat due to a higher radiant emission rate. Local zone heating might be supplied via hot water pipes in the floor. Electric heaters or propane heater might also be used as artificial heat sources. Propane heaters are burning gas and will therefore produce water, which adds to the moisture load of the building. This means that ventilation rate and energy use is higher with this type of heat supply.

Summer ventilation

During the summer the temperature difference between inside and outside is low and animal heat production is just adding to the heat load of the building. This means that it is necessary to move a great amount of air through the building to remove excessive heat. Generally, it is not possible to maintain inside temperature less than 5 C higher than outside temperature unless cooling is applied. Cooling might be applied via cooling pads placed along the outside walls of the building. However, it will only be effective in climatic zones with low relative humidity during summer. In a dry hot climate like the interior of Spain the temperature might be reduced by 10-12 C by passing the ventilation air through an evaporative cooling pad, which is a cellulose pad that has water trickling through it. When the dry air enters the pad water is evaporated, which means that sensible heat is converted to latent heat in a so-called adiabatic process meaning that the process in itself is not requiring any energy. Another and more simple way of cooling the animals during the summer is via drip cooling, which is usually used in farrowing and gestation units. This system works by water that drips from a pipe onto the animal’s nose, which has many veins and therefore is quite efficient in removing heat from the body. Recently, high pressure cooling systems has been introduced as an alternative to evaporative cooling pads. This system works by spraying a mist of water in the room, which then evaporates and cools down the room. In a dry and hot climate it must be running continuously in order to reduce temperature and in that case relative humidity becomes too high.