Emissions (II): How to minimize GHG and ammonia emissions on pig farms

This article describes different techniques that can be applied, in order of priority, to prevent NH3 and CH4 emissions.

The pig sector events all around the world

Weekly newsletter with all the pig333.com updates

Swine industry news in your email

Pig health: news and articles on PRRS, PCV2, biosecurity, etc, Pig disease guide, atlas of pathology, clinical cases…

Biocheck.UGent is an independent, risk-based, scientific scoring system for assessing the quality of your on-farm biosecurity.

A visual and practical step-by-step guide on how to perform a necropsy on a pig.

All the information about ASF: how to recognize the disease, how it is transmitted, pictures of lesions, latest news, guides, etc.

All the information on Foot and Mouth Disease in pigs: how to recognize the disease, how it is transmitted, images of lesions, latest news, guides,...

Description of the most important diseases and conditions in pigs

Images of major swine diseases

Pig disease diagnostic tool

Definition for the most commonly used pig terms

Simulator that calculates the amount of drug to add to the water when using a flow dispenser.

Weekly newsletter with all the pig333.com updates

Pig Prices by countries. Pork production and trade. News of the pig market and the raw materials

The latest slaughter pig prices in the most important pig markets. Check the evolution of the historical prices in charts and in several currencies.

Latest quotations for the main commodities used in pig feed. Historical graphs with the pig price and estimated feed price.

Figures & trends in pig numbers, pork production and pork trade.

Global production and trade data for the most important raw materials

Weekly newsletter with all the pig333.com updates

Articles on nutrition and pig feeding, characteristics of raw materials and additives for pig feed. Prices of raw materials

Latest quotations for the main commodities used in pig feed. Historical graphs with the pig price and estimated feed price.

Technical sheets of the main raw materials and additives used in swine feed. They include a comparison of nutritional values from various sources, product

Global production and trade data for the most important raw materials

Definition for the most commonly used pig terms

Use this tool to diagnose problems with the feed conversion ratio. Click on the flowchart or on the buttons within the text to navigate through the different parts of the tool.

A biweekly newsletter with the latest developments in swine nutrition

Articles on genetics and pig reproduction: genetic improvement, genomics, artificial insemination, use of hormones

Compare production data, calculate the number of sow, nursery, and finishing spaces, and visualize your tasks on the work schedule by type of BMS.

Tool that allows you to calculate the replacement rate in your farm

Definition for the most commonly used pig terms

Use this tool to find out why your farrowing rate is less than ideal. Click on the flowchart or on the buttons found within the text to navigate through the different parts of the tool.

Weekly newsletter with all the pig333.com updates

Management, pig farm management, work planning in each production stage: management in gestation, grow finish, batch farrowing

Compare production data, calculate the number of sow, nursery, and finishing spaces, and visualize your tasks on the work schedule by type of BMS.

Tool that allows you to calculate the replacement rate in your farm

Definition for the most commonly used pig terms

Weekly newsletter with all the pig333.com updates

Design of facilities and equipment for pig farms: building design, climate control, feeding systems, etc.

Biocheck.UGent is an independent, risk-based, scientific scoring system for assessing the quality of your on-farm biosecurity.

Environmental Footprint Calculator along the pork value chain.

Definition for the most commonly used pig terms

Simulator that calculates the amount of drug to add to the water when using a flow dispenser.

Use this tool to explore which slurry management strategy best fits your situation. Click on the flow chart or on the buttons within the text to navigate through the different parts of the tool.

Weekly newsletter with all the pig333.com updates

What makes us stand out is the quality and independence of our contents. Find out about the authors who make it possible. Our goal is to generate a virtual community of advanced users in the sector.

Xavier Flotats Ripoll is a doctor of industrial engineering.

Project Engineer of TApS (Solar Harnessing Technology) from 1981 to 1986

Professor of environmental engineering at the University of Lleida (UdL) until 2005

Director of the Technological Centre GIRO (Integral Management of Organic Waste) from 2005 to 2012

Professor at the Universidad Politécnica de Cataluña (UPC) since 2009.

Currently he is a professor emeritus.

His academic and professional activity has focused on organic waste management and the study, development and mathematical modelling of transformation processes, especially anaerobic digestion and biogas production from livestock manure. His professional activity includes the biogas plant at the Mas El Cros pig farm (Santa Pau, Girona), which he designed in 1981 and operated from 1983 to 2003 (energy saving award 2002). He is an honorary member of AEBIG (Spanish Association of Biogas).

Updated CV 14-Nov-2019

This article describes different techniques that can be applied, in order of priority, to prevent NH3 and CH4 emissions.

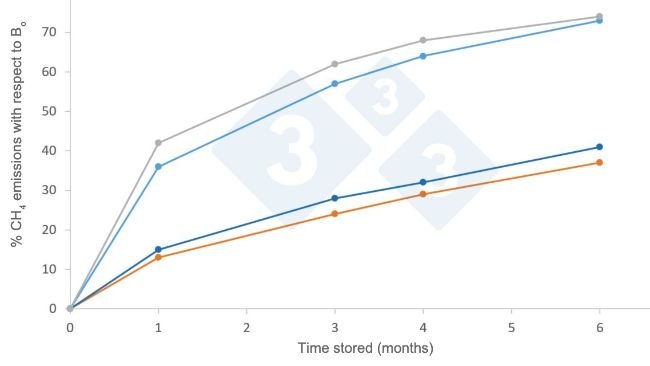

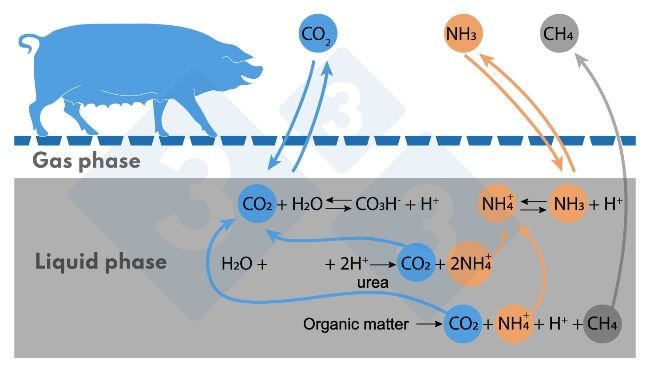

In this first article on emissions, Xavier Flotats explains how the main greenhouse gases and ammonia are generated on our farms.

Using solar energy to evaporate part of the water from the slurry can be of interest, avoiding volatization of ammonia. Solar drying can be combined with other strategies.

Removing nitrogen from slurry by transforming it into N2 can be done biologically or by physical-chemical methods, the latter of which are in the experimental phase for slurry.

Although these strategies do not include anaerobic digestion in the combination of processes and therefore do not take advantage of its benefits, they do provide a higher organic matter content in the recovered effluents.

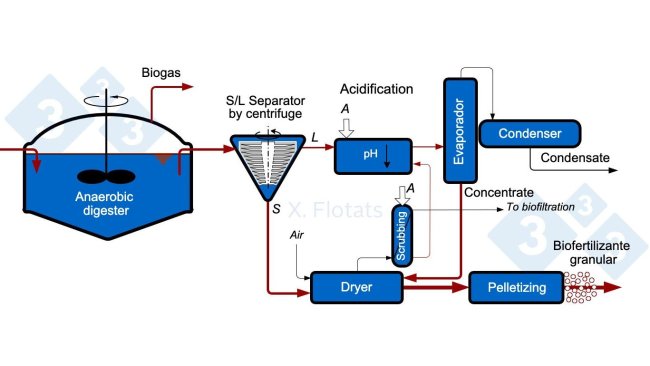

In a surplus situation, the best option is to export the digestate obtained following anaerobic digestion. If the cost of transportation is not affordable, other alternatives should be considered. Here we explain which ones.

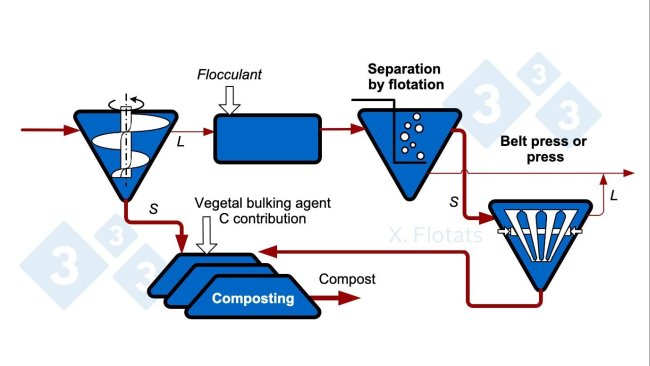

Composting pig manure results in a product that can be sold in the organic amendment, horticulture, and gardening market.

Among other things, anaerobic digestion improves the fertilizer quality of slurry and reduces odors and GHG emissions. The choice to use this or not will also depend on the justification of the cost, i.e. whether it allows for energy savings on the farm or whether it provides an income from the sale of the energy generated.

Solid/liquid slurry separation systems improve the subsequent management of the slurry, such as its transport or further treatment of each fraction.

Acidification of slurry prevents the formation of ammonia and its loss by volatilization, reducing the loss of fertilizer value of the slurry.

In a situation with a nutrient surplus, the cost of transport is often the most important limiting factor to consider when deciding on the best manure management system for the farm.

In a situation of nutrient balance between the nutrients produced and the needs of the crops, priority is given to the transport and application management and the fertilizer quality of the slurry. Which systems allow me to optimize these?

The complexity of our situation and the objectives to achieve will depend on the results of the nutrient balance. Where do I stand? We'll help you answer this question.

Slurry lagoons, and manure holdings in general, are fundamental tools for regulating the balance between the virtually continuous production of manure and its seasonal application to fields as fertilizer.

Fertilization is the most direct and simplest way to give value to our slurry. Here we explain several points to take into account for proper fertilization of your soils and crops.

Reducing slurry at the source means modifying production guidelines to reduce environmental effects and improve the subsequent management of slurry.

Welcome to 333

Connect, share, and interact with the largest community of professionals in the swine industry.

Celebrating 195501Users on 333!

Sign upAlready a member?