This indicates customers are valuing from AusScan's world first calibrations for pig digestible energy (DE), poultry apparent metabolisable energy (AME) and ruminant metabolisable energy (ME) for cereal grains, as well as all amino acids, including reactive lysine in soybean and canola meals.

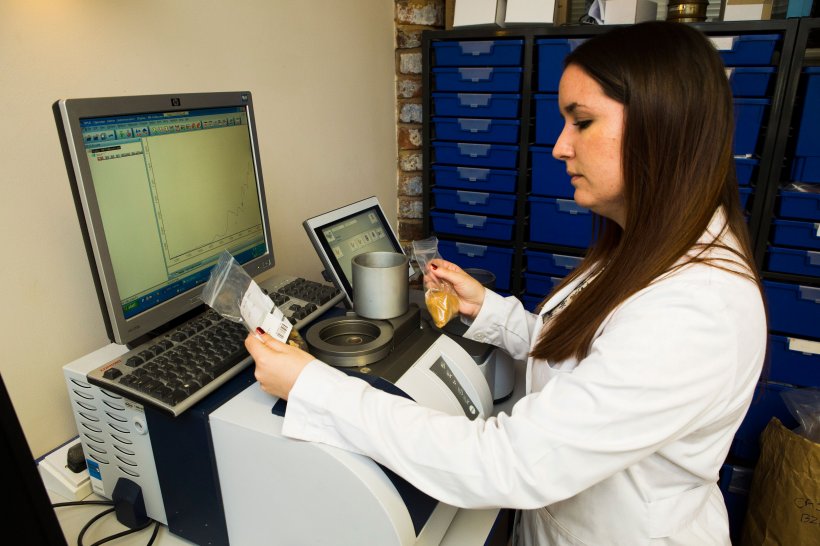

AusScan uses unique near infrared reflectance spectroscopy (NIRS) calibrations.

According to globally respected animal nutritionist Tony Edwards, principal of South Australia based ACE Livestock Consulting, the undersupply or oversupply of energy in diets can result in further increased costs due to reduced performance of livestock.

“Accessing AusScan calibrations provides nutritionists with the digestible energy of grains before feeding livestock, allowing more accurate formulations,” he said.

With current high grain prices, one MJ DE/kg can cost $25-30 per tonne.

“AusScan energy calibrations can also help producers confidently select the correct parcels of grains for composite diets,” Mr Edwards said.

AusScan has scanned more than 10,000 soybean meal samples and the reactive lysine content is shown to vary due to differences in processing.

When evaluating the amount of reactive lysine in feedstuffs as a measure of heat damage it is important to consider reactive lysine as a proportion of the total lysine.

Most global soybean samples surveyed have shown reactive lysine as a proportion of total lysine above 72%. However, there were samples as low as 65% reactive lysine.

Notable variation was observed across these samples, with total lysine levels (as is) ranging from 21.0 to 31.5 g/kg.

Tony Edwards believes that feeding animals reduced reactive lysine content can have negative effects on daily gain, feed efficiency and days to slaughter.

“Using the reactive lysing calibration from AusScan allows for a rapid cost effective analysis of the reactive lysine content and provides a better understanding of the variation of reactive lysine due to heat damage found in oil seeds,” he said.

“Further, nutritionists now have the opportunity to formulate diets with more precision and cost savings.”

November 10, 2017 - Pork CRC.