The key word for research and new development is bionics – learning from nature and achieving technical implementation. The manufacturer of energy systems, Roering GmbH in Vreden/Germany developed a new kind of high performance fermenter – the UDR fixed-bed fermenter. Therefore, farm animals were the example; their rumen and intestine structure shows lamellar intestinal villi and lobes, on which micro-organisms adhere and commute organic material within a very short period energetically. In the UDR fermenter appears the same method. The upflow- and downflow reactors (UDR) are each fitted with a fixed-bed register, which provide large surface areas for high concentrated settlement of bacteria. By the added retention of biomass (reflow tank) a rapid biological implementation process is possible. The patented UDR fixed-bed reactors guarantee high efficiency with a minimum of energy consumption.

The key word for research and new development is bionics – learning from nature and achieving technical implementation. The manufacturer of energy systems, Roering GmbH in Vreden/Germany developed a new kind of high performance fermenter – the UDR fixed-bed fermenter. Therefore, farm animals were the example; their rumen and intestine structure shows lamellar intestinal villi and lobes, on which micro-organisms adhere and commute organic material within a very short period energetically. In the UDR fermenter appears the same method. The upflow- and downflow reactors (UDR) are each fitted with a fixed-bed register, which provide large surface areas for high concentrated settlement of bacteria. By the added retention of biomass (reflow tank) a rapid biological implementation process is possible. The patented UDR fixed-bed reactors guarantee high efficiency with a minimum of energy consumption.Since November 2010 Roering GmbH is successfully concerned in a seminal pilot project, for which a modern biogas plant was constructed to generate biogas by fermentation of sugar-beets. The permanent supply of the plant is carried out by a new procedure: The automatic feeding of liquid ensiled sugar-beets. This venture is watched on the market with great interest. The fermentation of sugar-beets is due to the high digestibility and quick biomass conversion an effective option to common corn ensilage. Also for that special use, UDR fixed-bed fermenters ensure a maximum utilizsation at minimum required space and energy demand.

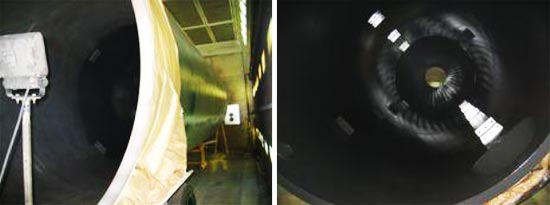

For the internal coating of the UDR-reactors our high performance product PROGUARD CN 100 LV-2 is used, which offers excellent resistance against the chemical attack of biogas and biomass. It also provides steady protection against various substances such as: ammonia gases, sulfuric acids, hydrogen sulfides and organic acids resulting from variable pH-value and oxidative effect of the fermenting mass in the biogas fermenter. The revolutionary development of Roering GmbH combined with PROGUARD CN 100 LV-2 feature outstanding effectiveness for the whole biogas-sector.

The PROGUARD product line of Ceram Kote International GmbH shows versatile physical properties and excellent chemical resistance. For specific requirements we generated high-value coating products for biogas plants with patented integration of special-biocide-crystals, which provide targeted protection against anaerobe bio corrosion and resulting pitting corrosion.

Ceram Kote International GmbH