Finding the most efficient method of feeding pigs has been a never ending quest for producers and equipment suppliers alike. Hand feeding and automatic, gravity-flow feeders dominated the industry until the development of mechanical-flow feeding in the 1980s. This development revolutionized the industry and the only mechanically-operated feeder, the Osborne Big Wheel® Feeder, quickly became the #1 selling hog feeder in the U.S. However, as the industry moved toward wean-to-finish, producers often found no commercially-available feeding systems were adequate in a wean-to-finish environment. The best gravity-flow feeders worked well for newly weaned pigs, but as pigs grew, play waste and overloading of the trough became a maintenance nightmare. Alternatively, mechanical-flow feeders provided never-before-seen feed savings, but sometimes required assistance to help pigs get started on the feeder.

Finding the most efficient method of feeding pigs has been a never ending quest for producers and equipment suppliers alike. Hand feeding and automatic, gravity-flow feeders dominated the industry until the development of mechanical-flow feeding in the 1980s. This development revolutionized the industry and the only mechanically-operated feeder, the Osborne Big Wheel® Feeder, quickly became the #1 selling hog feeder in the U.S. However, as the industry moved toward wean-to-finish, producers often found no commercially-available feeding systems were adequate in a wean-to-finish environment. The best gravity-flow feeders worked well for newly weaned pigs, but as pigs grew, play waste and overloading of the trough became a maintenance nightmare. Alternatively, mechanical-flow feeders provided never-before-seen feed savings, but sometimes required assistance to help pigs get started on the feeder.

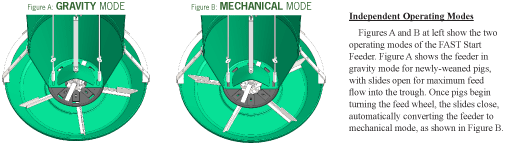

Now, Osborne Industries, Inc., the industry-leading innovator in pig feeding, is pleased to announce its latest advancement in their signature line of “no-waste” pig feeders. The new FAST Start™ wean-to-finish feeder features all the no-waste, feed saving aspects of the Big Wheel family of mechanical-flow feeders, but operates in gravity-flow mode for newly weaned pigs. The feeder then automatically converts to mechanical-flow as pigs grow. Osborne’s new feeder will be introduced at the World Pork Expo, June 7-9, 2017, in Des Moines, Iowa, USA, at booth V451.

Osborne’s President & CEO, Mr. George Eakin, said, “The FAST Start Feeder is an answer to the age-old problem of designing a feeder that is capable of feeding very young pigs, and yet, prevents the excessive feed waste that occurs when pigs grow. Traditional gravity-flow feeders start very young pigs easily, but adjusting them to prevent feed waste throughout the growing cycle is a management nightmare.”

Eakin continued, “The FAST Start Feeder combines gravity-flow feed delivery for newly weaned pigs with mechanical feed delivery for finishing pigs, which saves feed and ensures feed freshness. The conversion of the FAST Start Feeder from a gravity-flow feed delivery to the feed-saving mechanical-flow delivery is done automatically by the pigs. This automated feature allows pigs to grow from wean to finish on a single feeder without any adjustments, and yet save feed, ensure feed freshness, and grow animals efficiently.”

When weaned pigs are put on the feeder, small slides in the feed hopper bottom are open, allowing feed to freely flow into the trough. As pigs grow, they begin turning the multi-spoke feed wheel in the bottom of the trough, which closes the slides on the feed hopper bottom. A feed sweep, located in the bottom of the feed hopper and attached to the feed wheel, sweeps feed past the cone and out of the hopper to the trough. Feed falls through the center hole into the trough, where the feed wheel dispenses it to the pigs. Feed stops flowing when pigs stop moving the wheel, allowing for the automatic conversion from gravity to mechanical flow.

Based on numerous on-farm trials by users, the FAST Start Big Wheel Feeder has been observed to meet all the critical performance standards cited by leading veterinarians for wean to finish, but without losing any of the well-known Osborne “no-waste” feeding during finishing. Independent producer, Jeff Dohrman, Bushton, Kan., said, “The first thing I noticed after installing the feeder was that there was always feed in the trough. Then, within 10 days to two weeks, the pigs start spinning the wheel, automatically turning into a mechanical Big Wheel. There is no problem getting pigs started on this feeder. It’s done a really good job.”

Made of abrasion and corrosion-resistant RTM-molded plastic, a material Osborne developed and perfected over the past 30 years, the feeder operates with minimal maintenance for years. No other round feeder compares to the quality of the Big Wheel Feeders.

Osborne Big Wheel Feeders, manufactured and assembled in Osborne, Kansas, USA, are distributed worldwide. See Osborne’s new FAST Start wean-to-finish feeder at booth V451 at the World Pork Expo in Des Moines, Iowa, June 7-9, 2017.

May 30, 2017 - Osborne